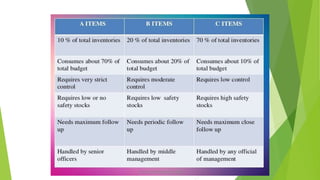

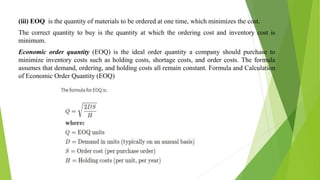

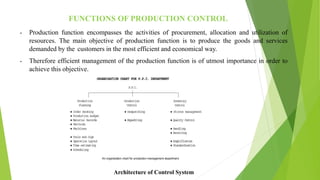

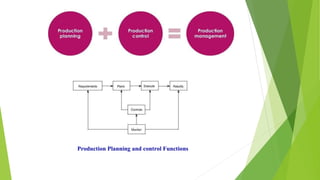

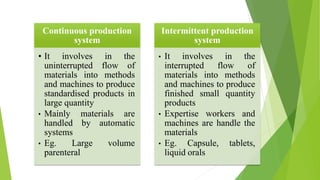

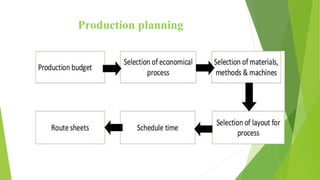

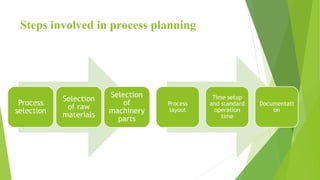

This document provides an overview of inventory management, production planning, and control. It discusses key objectives like minimizing costs and ensuring adequate supply. Inventory management techniques include ABC analysis, VED analysis, EOQ, lead time, and buffer stock. Production planning determines facility requirements and layout, while production control monitors plan execution and addresses deviations. The perpetual inventory system uses bin cards, store ledgers, and continuous stock taking to regularly check and prevent stockouts.