The document discusses inventory management concepts including:

1. Types of inventory like raw materials, work in process, and finished goods.

2. Inventory functions like meeting demand, smoothing production, and protecting against stockouts.

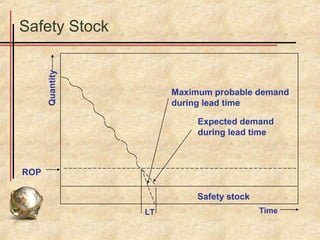

3. Effective inventory management requires tracking inventory levels, forecasting demand, and estimating costs of holding, ordering, and shortages.

4. Classification systems help prioritize inventory items for control based on factors like importance, value, or demand pattern.