- Inventory constitutes a significant part of current assets for many companies, often around 60% of current assets. Effective inventory management is important to avoid unnecessary costs and ensure profitability.

- There are different types of inventory including raw materials, work in progress, and finished goods. The objectives of inventory management are to maintain optimal inventory levels for smooth operations while minimizing costs.

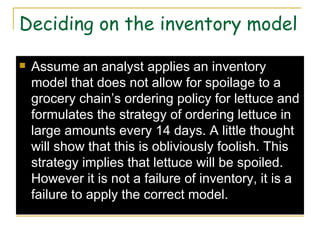

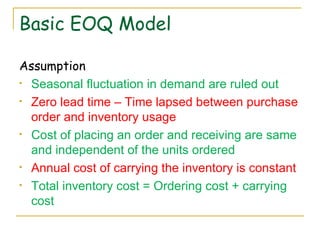

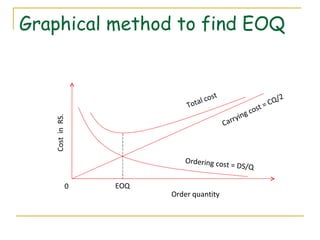

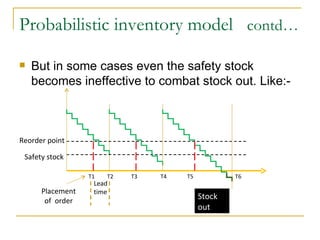

- An optimum inventory level balances ordering costs, carrying costs, and stock-out costs. Both over-investment and under-investment in inventory can be dangerous for a company. Effective inventory management tracks inventory levels and determines when and how much to order.