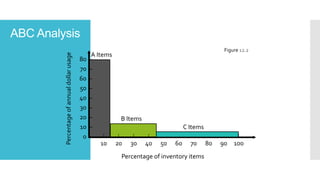

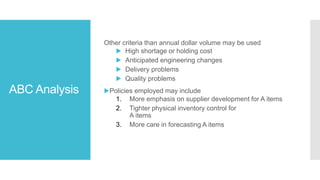

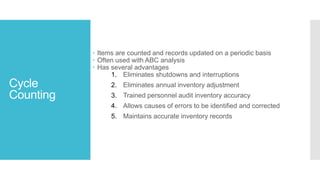

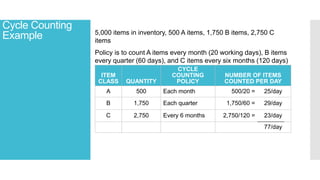

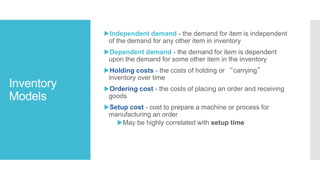

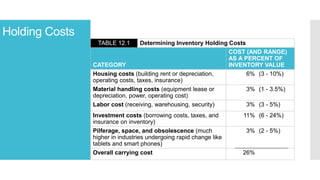

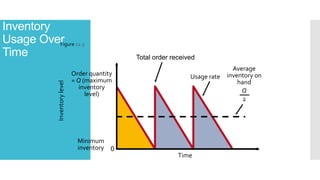

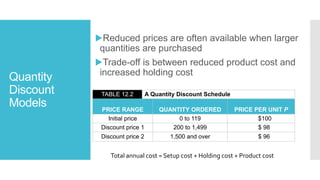

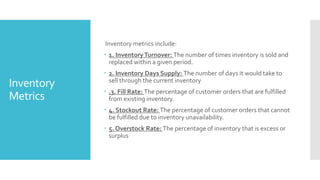

Chapter 6 focuses on inventory management, emphasizing the balance between inventory investment and customer service. It discusses various types of inventory, functions, and critical inventory management techniques such as ABC analysis, cycle counting, and risk pooling. Key inventory metrics like inventory turnover and carrying cost are highlighted to assess efficiency and profitability.