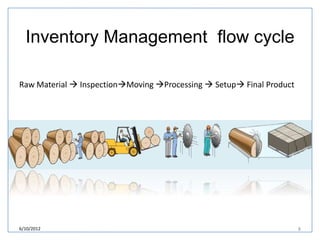

This document discusses inventory management. It defines inventory as stock held to meet future demand. There are different types of inventories like raw materials, work in progress, and finished goods. Inventory management involves tasks like tracking inventory levels, determining how much to order and when to order. It describes the inventory management flow cycle and different models used like economic order quantity and production order quantity. Maintaining inventory provides benefits like decoupling production processes, ensuring variety for customers, and taking advantage of quantity discounts. Reasons for keeping stock include time lags in the supply chain, variations in demand and lead times, and achieving economies of scale.