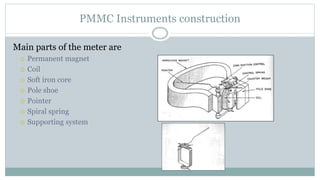

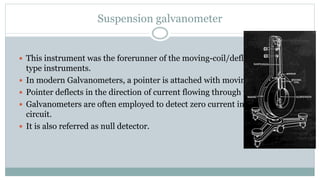

Electromechanical instruments measure electrical quantities using a moving coil within a magnetic field and a pointer to indicate the measured value on a calibrated scale. Permanent magnet moving coil (PMMC) instruments are a common type of deflecting instrument. They contain a permanent magnet that produces a magnetic field, a coil that moves within the field, and a pointer attached to the coil. Three forces act on the moving coil: deflecting force from current in the coil, controlling force from a spiral spring, and damping force from eddy currents induced in the core. Together these forces allow the pointer to indicate the measured value while damping oscillations.