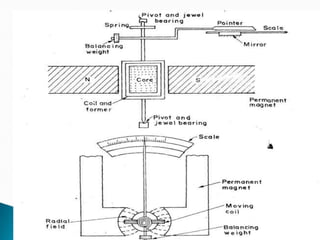

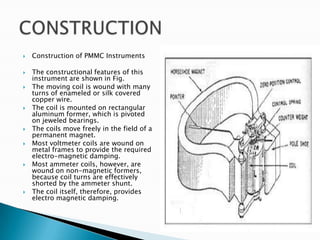

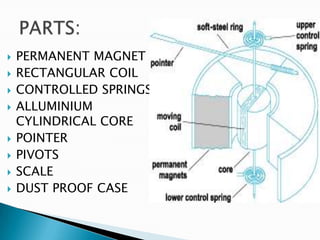

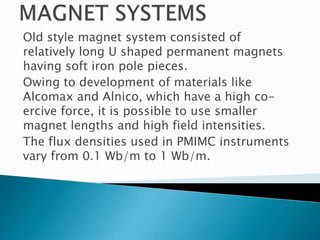

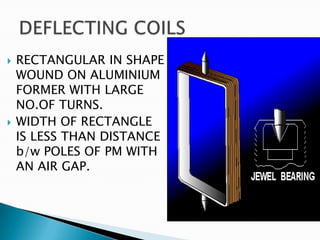

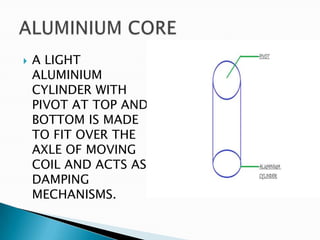

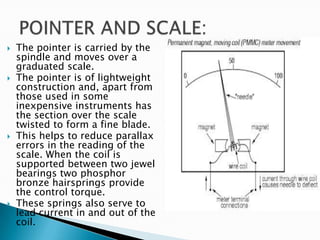

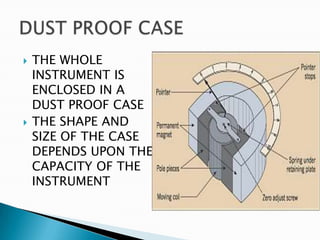

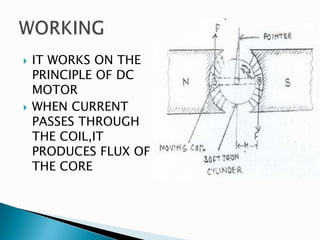

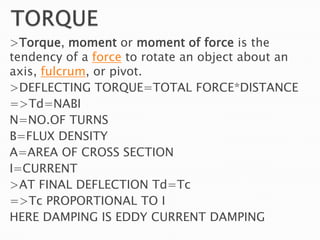

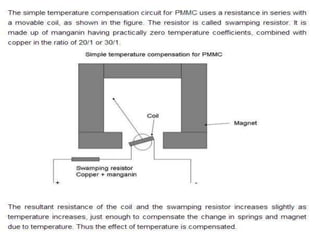

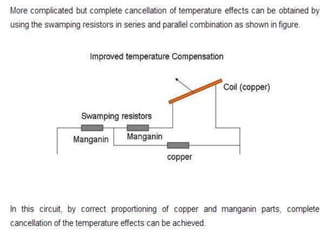

The document describes the construction and working of a permanent magnet moving coil (PMMC) instrument. It has a rectangular coil wound with copper wire that is mounted on a pivoted aluminum former and moves freely in the field of a permanent magnet. The coil is controlled by springs and damped using eddy currents produced in an aluminum cylinder. Current passing through the coil experiences an unbalanced magnetic field that produces a torque proportional to the current.