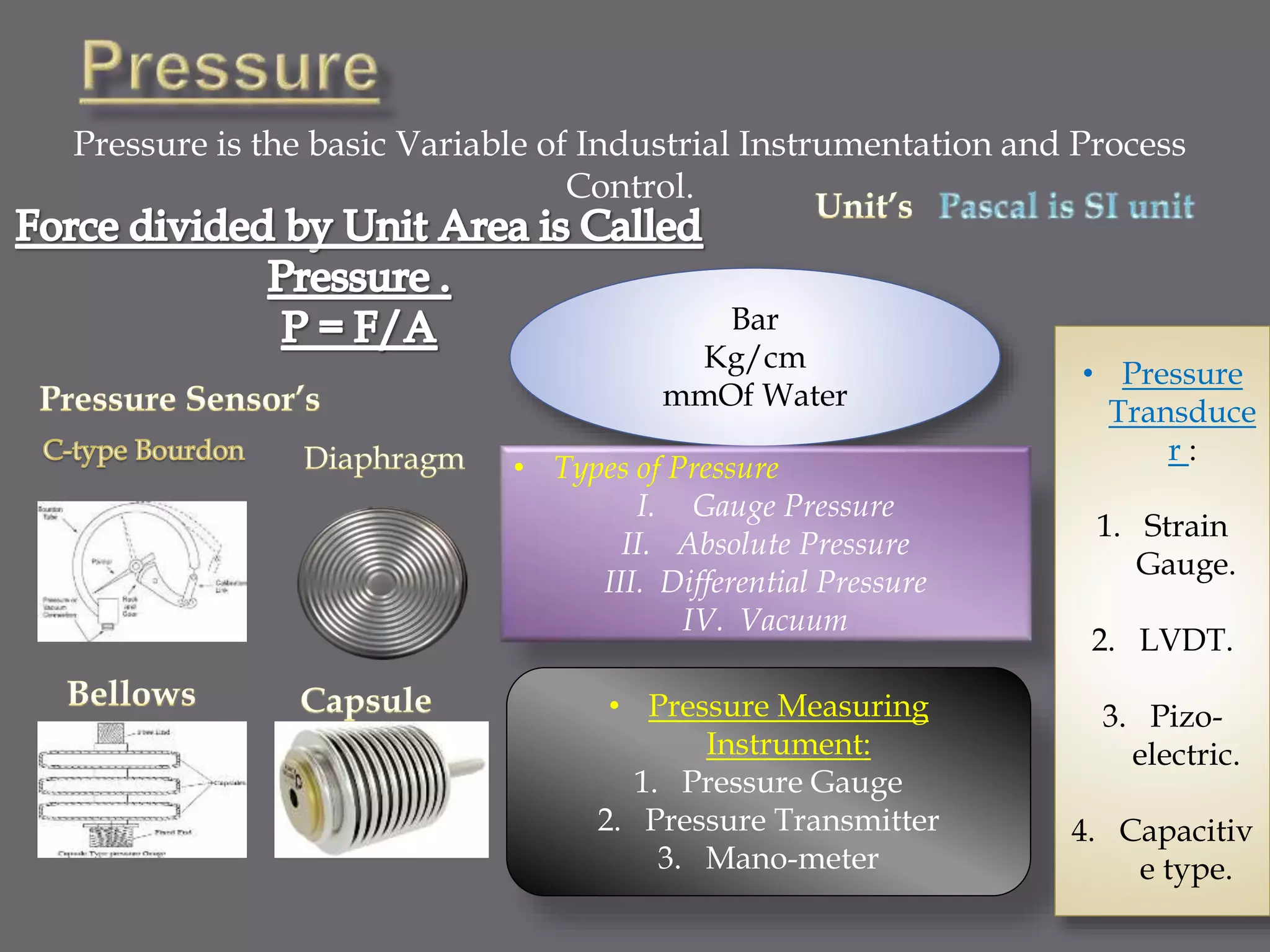

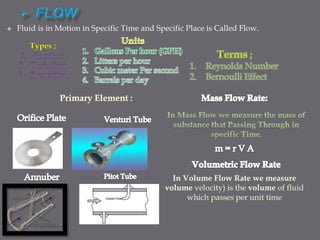

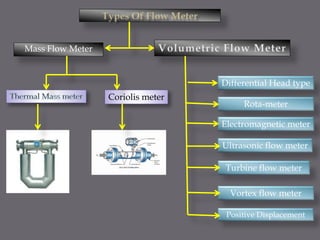

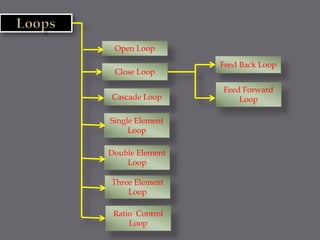

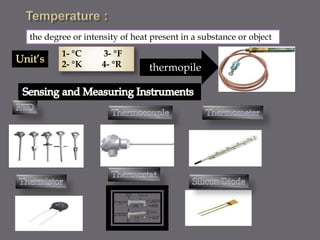

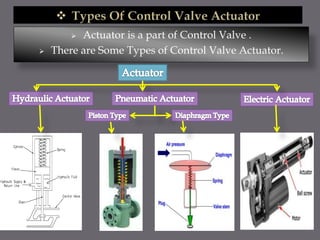

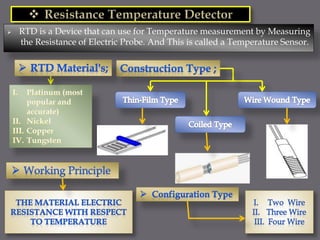

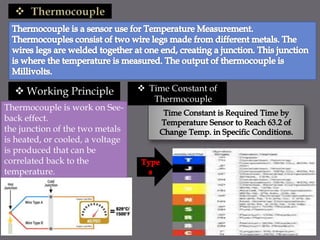

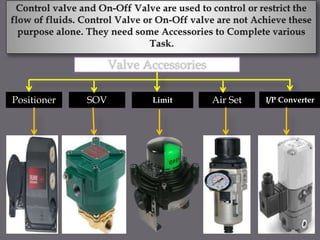

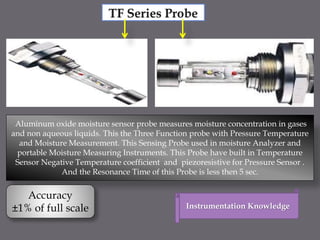

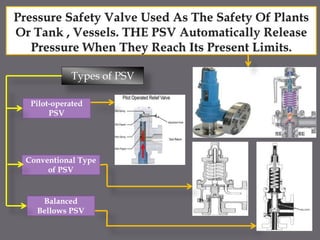

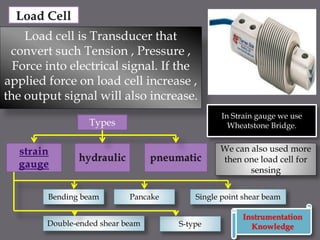

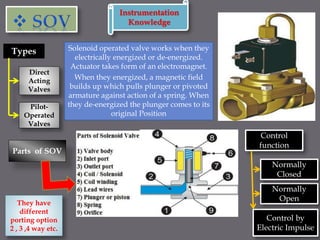

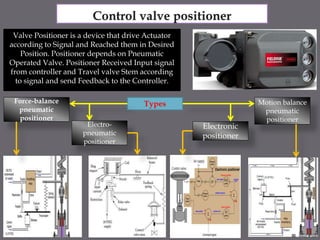

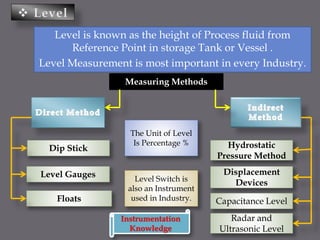

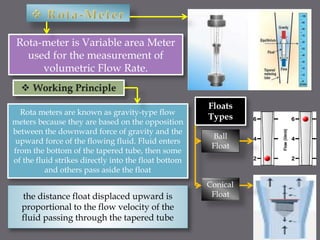

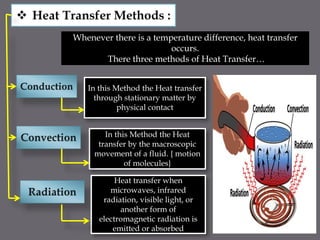

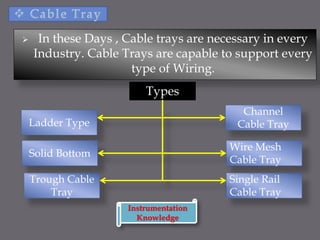

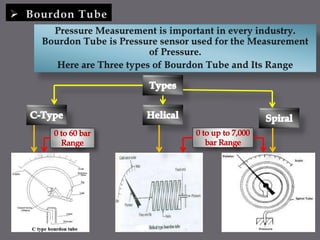

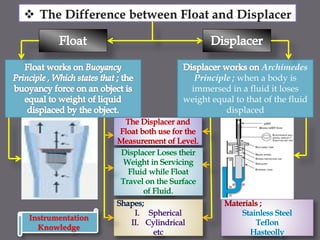

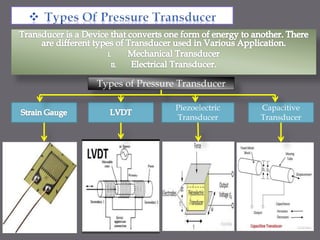

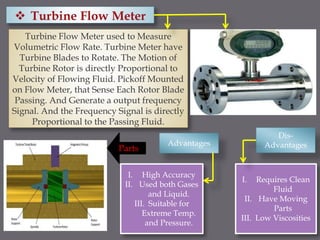

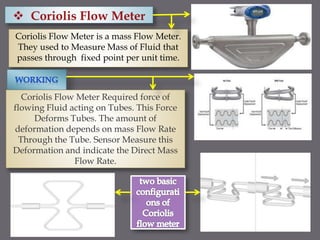

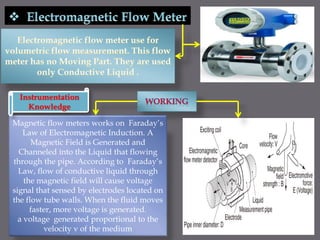

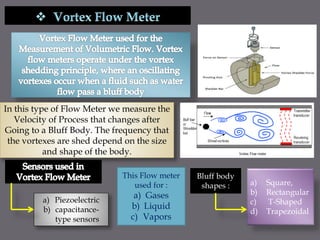

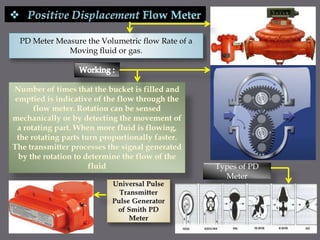

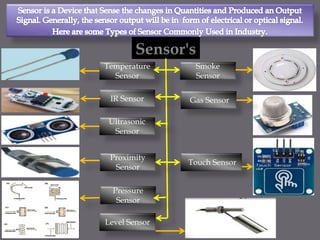

The document provides an overview of various industrial instrumentation and process control components, including types of pressure, flow measurement, temperature sensors, level gauges, and control valves. It details different methods and devices used for measuring and controlling pressure, temperature, flow rates, and levels in industrial settings, as well as safety devices like fire alarms. Additionally, it covers electronic components, types of flow meters, and principles related to their operation and accuracy.