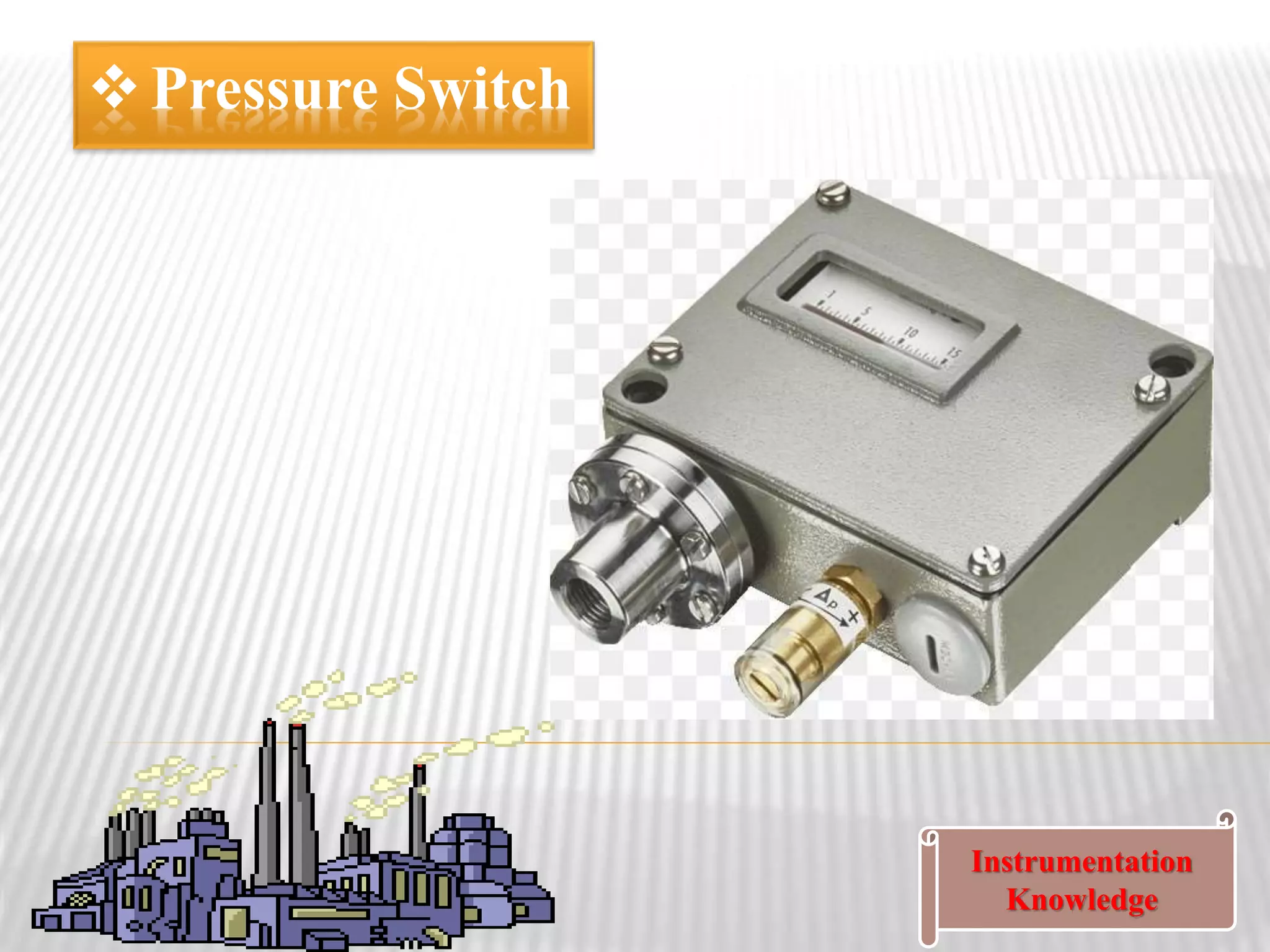

Pressure switches are used to detect the presence of pressure in industrial systems using pressurized fluids. Pressure switches contain a piston or diaphragm that moves when pressure reaches the switch's set point, triggering electrical contacts to open or close. There are normally open and normally closed contacts, such that when pressure reaches the set point the normally open contact closes and normally closed contact opens. Pressure switches can be calibrated by connecting them to an air source and pressure gauge and adjusting the tension spring to set the trigger point for contact switching at the desired pressure level.