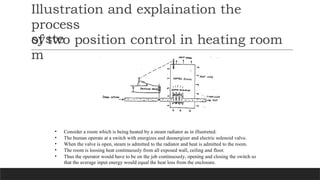

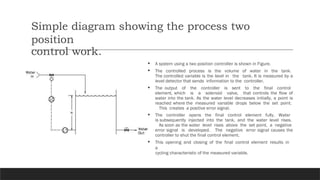

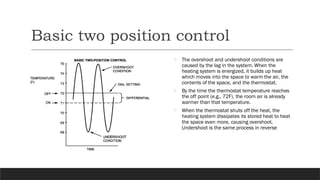

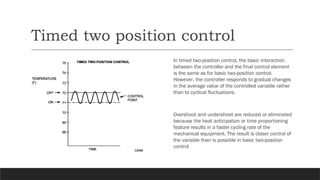

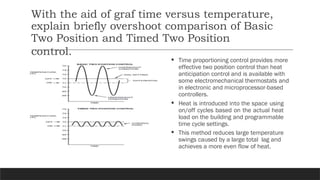

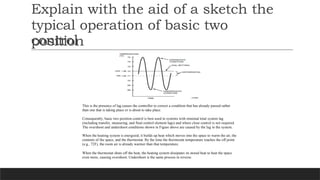

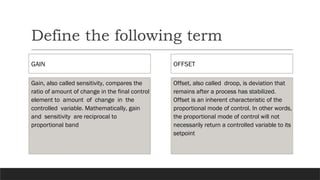

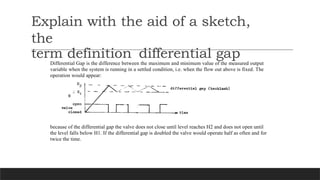

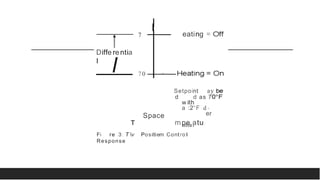

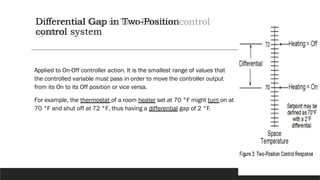

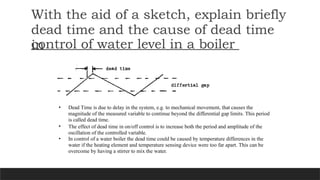

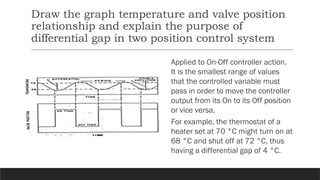

The document discusses two-position control systems, which are on-off controllers used for managing devices like heaters and water levels in tanks through simple control loops. It explains the operation, advantages, and limitations of both basic and timed two-position controls, highlighting concepts such as overshoot, undershoot, differential gap, gain, and offset in control systems. Additionally, it addresses factors affecting control response, like dead time and system lag.