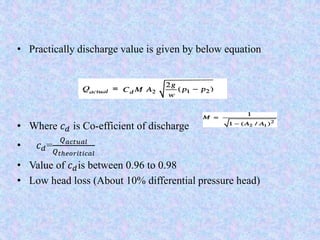

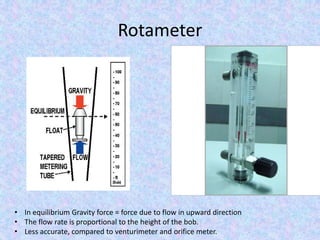

The document discusses various instrumentation techniques used in oil refineries for measuring key parameters such as pressure, temperature, flow rate, and level. It details different flow measuring devices including venturimeters, orifice plates, pitot tubes, and ultrasonic flow meters, along with their principles of operation and advantages. Additionally, it covers temperature and level measurement methods, highlighting the importance of selecting appropriate sensors for improved accuracy and safety in industrial processes.