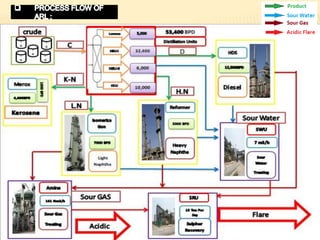

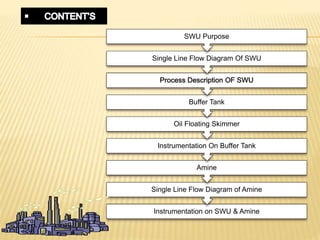

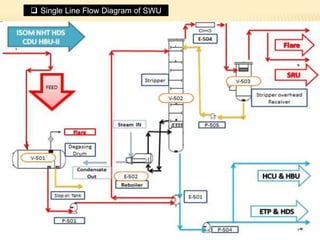

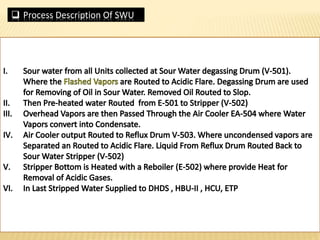

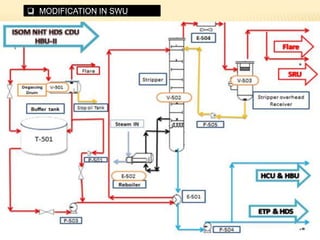

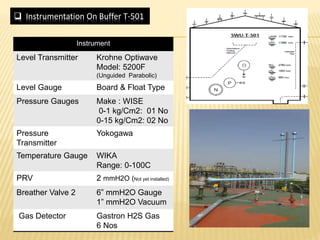

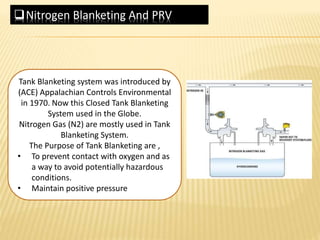

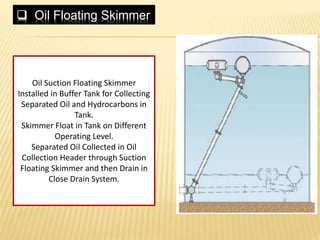

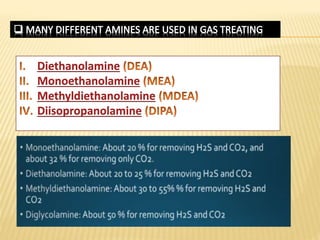

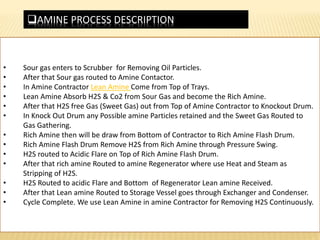

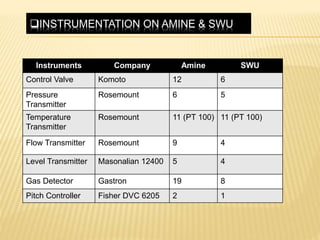

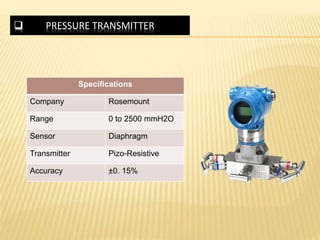

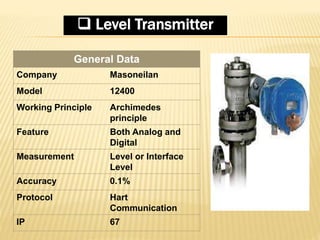

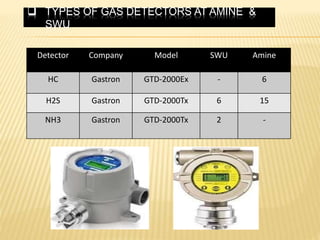

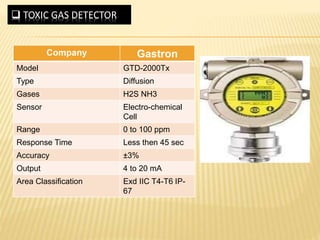

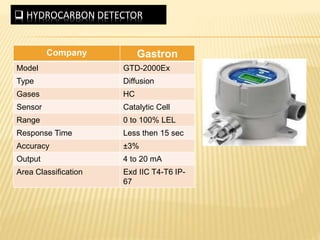

The document provides a comprehensive overview of the Sour Water Stripping Unit (SWU) and the Amine Unit, detailing their processes, instrumentation, and purpose. It outlines the removal of toxic components like hydrogen sulfide (H2S) and ammonia (NH3) from sour water and gas, as well as the modifications and equipment used in both units. Additionally, it includes specific details on various control systems and gas detection technologies employed to ensure safety and efficiency.