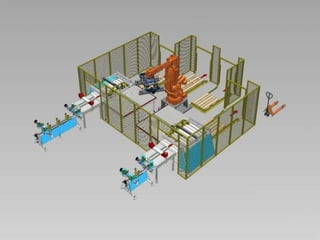

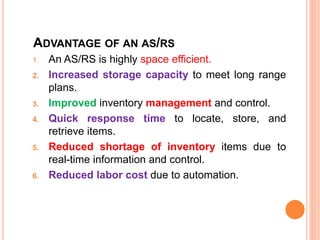

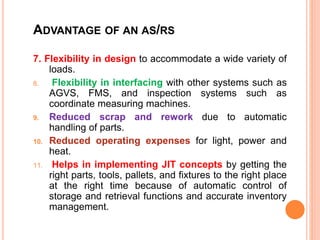

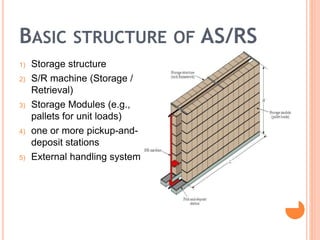

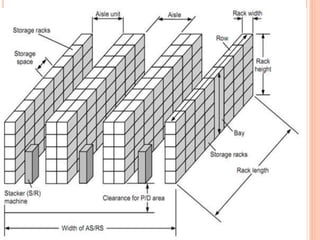

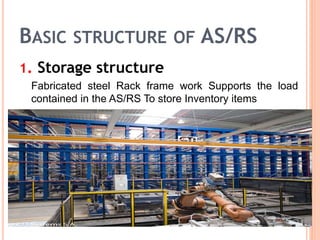

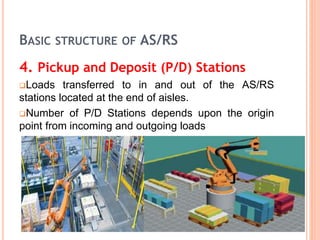

The document defines Automated Storage and Retrieval Systems (AS/RS) as systems that automate material handling processes, performing operations such as item removal, transportation, and storage without human intervention. Advantages of AS/RS include space efficiency, improved inventory management, reduced labor costs, and support for Just-In-Time (JIT) concepts. It outlines the basic structure of AS/RS, which consists of storage structures, storage/retrieval machines, storage modules, pickup and deposit stations, and external handling systems.