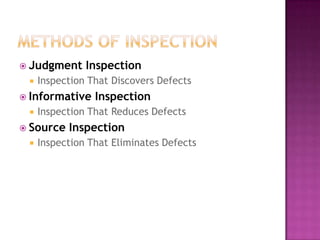

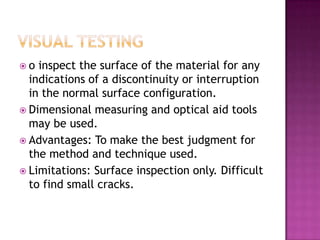

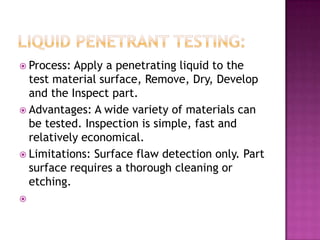

This document discusses different types of inspections used during the manufacturing process. It outlines floor inspection, fixed inspection, key point inspection, and final inspection. It then describes various inspection methods like visual testing, liquid penetrant testing, magnetic particle testing, ultrasonic testing, and radiographic testing. The objective of inspection is to check that a component works as intended, check the acceptability of manufactured products, and measure quality against predetermined standards. Inspection helps reduce defects, eliminate defective components, and ensure product quality.