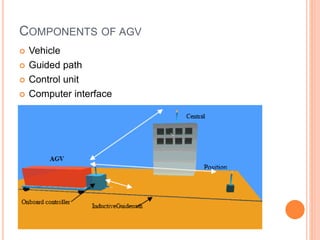

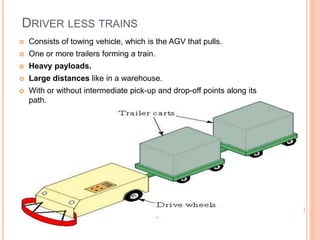

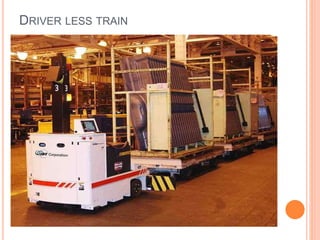

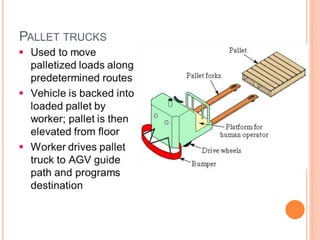

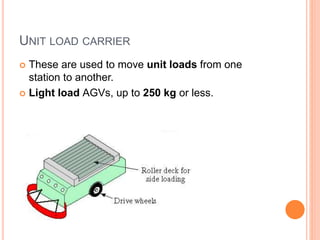

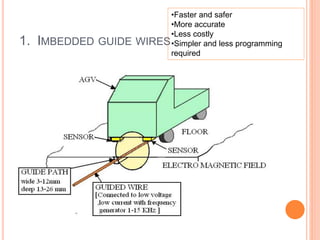

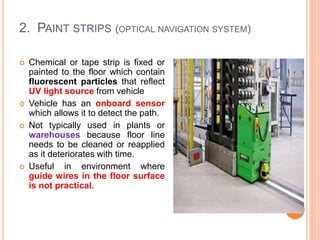

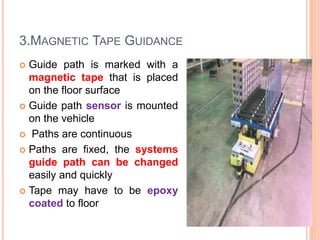

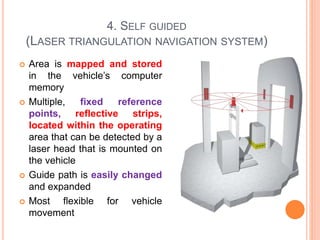

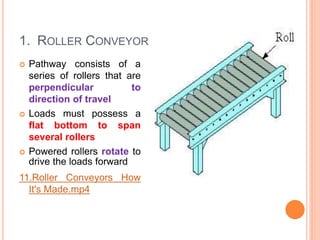

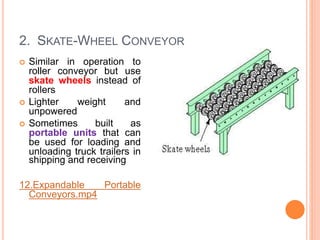

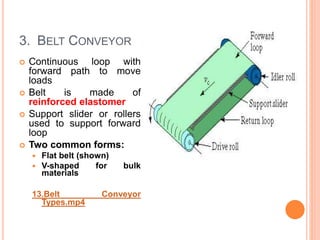

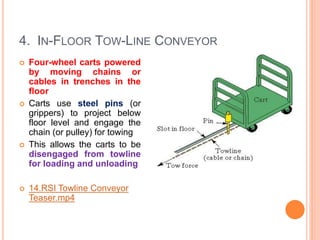

The document discusses automated material handling, including its definition, types of equipment, and benefits of automation such as increased productivity and improved safety. It details various automated guided vehicles (AGVs) and conveyor systems, outlining their components, types, and guidance technologies. Additionally, it mentions limitations of automated systems, including costs and maintenance requirements.