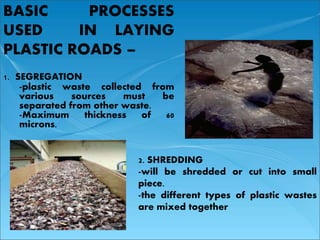

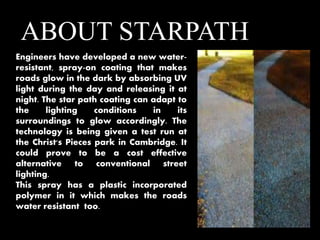

The document compares two innovative road construction methods: India's use of plastic waste combined with bitumen for durable, water-resistant roads, and the UK's Starpath, a spray-on coating that glows in the dark and serves as a streetlight alternative. While both innovations offer environmental benefits and improved road conditions, India's method addresses significant plastic waste issues and is economically advantageous in developing regions. Starpath, although more modern and energy-saving, is considered less feasible in India due to its higher costs and the pressing need for effective waste disposal.