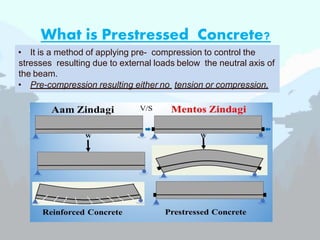

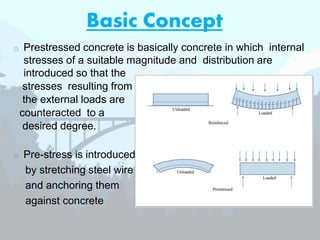

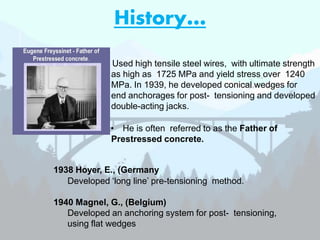

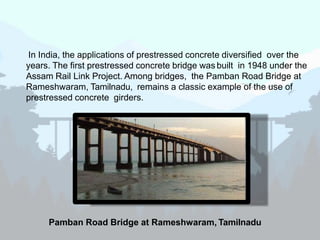

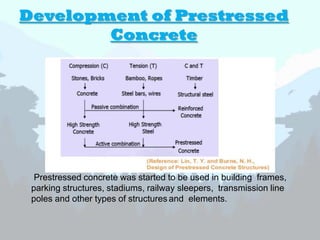

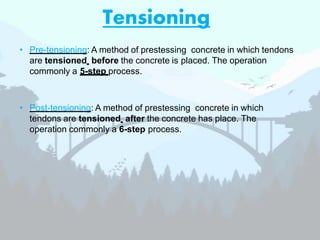

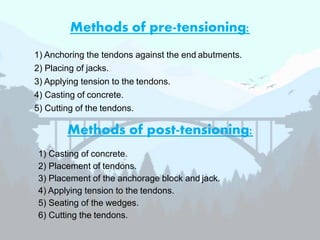

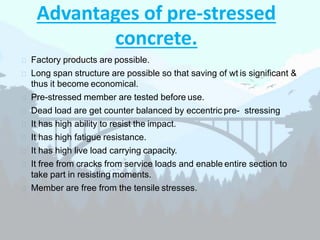

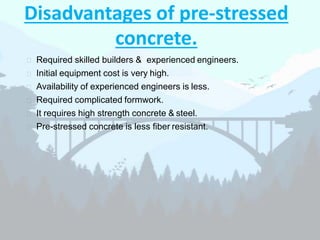

This document discusses prestressed concrete bridges. It begins with definitions of prestressed concrete as concrete with internal stresses introduced to counteract external loads. It then provides a brief history of prestressed concrete, noting key innovators. Examples of prestressed concrete bridges in India are given, including the famous Pamban Road Bridge. The document goes on to explain the basic principles, terminology, types, and methods of prestressing, as well as the advantages and disadvantages of prestressed concrete.

![DEPARTMENT OF CIVIL ENGINEERING

[2020-2021]

TRANSOPRTATION ENGINEERING

T.A.E. 2A

PRE-STRESSED CONCRETE BRIDGE

SUBJECT :-BRIDGE ENGINEERING

SUBMITTED BY :-

SHUBHAM DAS [TRE-I-A-18]](https://image.slidesharecdn.com/tae2a-210227033606/75/Pre-stressed-concrete-Bridge-1-2048.jpg)

![“Engineers like to solve problems. If there are no

problems handily available, they will create their

own problems.”

― Scott Adams

THANK YOU !!!

SUBMITTED BY :-

SHUBHAM DAS [TRE-I-A-18]](https://image.slidesharecdn.com/tae2a-210227033606/85/Pre-stressed-concrete-Bridge-14-320.jpg)