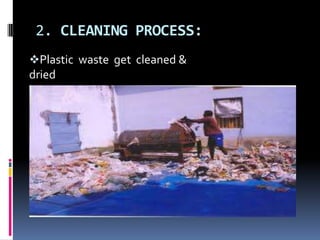

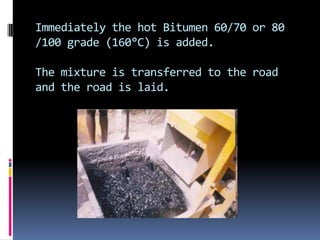

This document discusses using plastic waste in road construction. Plastic roads involve mixing shredded plastic waste like plastic bags and bottles with hot bitumen. Field trials show plastic can increase road strength and reduce costs. Advantages include using more plastic waste, reducing bitumen needs, and increasing road strength and lifespan. However, there are also disadvantages like toxic chemicals potentially leaching from the plastic and noxious gas releases during construction. The conclusion is that plastic roads could help strengthen infrastructure while improving the environment if the disadvantages around leaching and emissions can be addressed.