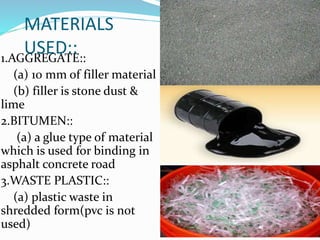

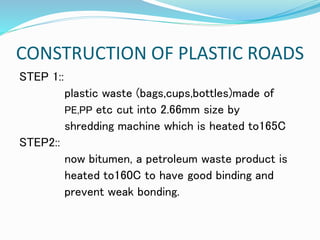

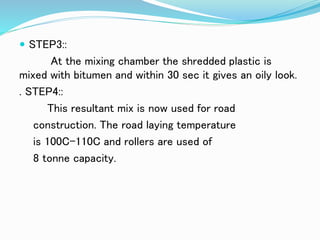

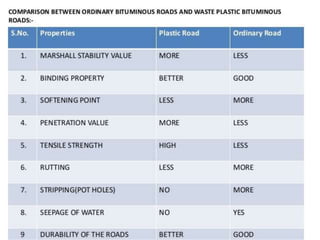

Plastic roads offer advantages over traditional asphalt roads. Plastic waste is shredded and mixed with bitumen to form a material that is more water resistant than traditional mixes. This allows plastic roads to last longer without cracks forming. Construction involves heating plastic waste and bitumen then mixing them to form an oil-like substance added to aggregate and laid like traditional roads. Using plastic waste in roads provides a way to reduce plastic disposal problems while saving money on road construction and maintenance over time.