Metal casting processes

•Download as PPT, PDF•

3 likes•348 views

The document discusses various metal casting processes and techniques. It covers topics like sand casting, pattern making, molding sand, cores, melting furnaces, and special casting processes. Sand casting is introduced as one of the most common casting methods where a sand mold is used. Key aspects covered include pattern materials and allowances, molding sand properties and testing, core types and testing, and common casting defects. Special casting techniques like shell mold casting, investment casting, and die casting are also summarized.

Report

Share

Report

Share

Recommended

Manufacturing technology unit 1(CASTING)

casting introduction, steps involved in casting,gating system,gates,pattern, patterns allowances, advantages and disadvantages of casting process and applications of casting process

Unit 1-METAL CASTING PROCESSES

1. The document discusses various metal casting processes and sand casting in particular. It describes the basic steps in sand casting including mould making, pouring, cooling, and removal.

2. Sand is commonly used as the mould material due to its low cost. It requires binders like clay to give it strength and hold its shape. The properties of ideal moulding sand and types of sands for different applications are explained.

3. Key aspects of sand casting like advantages, disadvantages, and factors affecting the properties of moulding sand are summarized. Common tests to evaluate moulding sand quality are also mentioned.

MANUFACTURING TECHNOLOGY-I

The document discusses manufacturing processes and sand casting. It defines manufacturing as making goods by hand or machinery. Manufacturing processes are classified into casting, joining, forming, sheet metal work, plastics processing, machining, powder metallurgy, heat treatment, and assembly. Sand casting is described as producing metal parts by pouring molten metal into sand molds. Molds are made using patterns, cores, and molding machines in a foundry. Sand casting can make complex shapes and is used to produce parts in large quantities.

Metal casting ppt1

Metal casting processes involve making a mold cavity using a pattern, melting and pouring metal into the mold, and allowing the metal to solidify. Key steps include preparing molds, melting and pouring metal, solidification, and inspection. Casting allows intricate shapes and wide material selection. Advantages are dimensional accuracy and surface finish can be limitations but new processes address these. Patterns are models of the final casting and come in various types depending on shape, size, and molding method. Careful pattern preparation helps minimize defects in the final casting.

MANUFACTURING TECHNOLOGY-I

The document discusses metal casting processes. It provides an overview of casting technology and classifications of solidification processes. Specifically, it describes sand casting processes including mold materials, open and closed molds, gating systems, risers, heating metal, pouring, and solidification of pure metals and alloys. Sand casting involves using expendable molds made of sand to form a cavity that shapes molten metal.

Casting process

The document discusses manufacturing technology and metal casting processes. It defines manufacturing as making goods by hand or machinery. Manufacturing technology is the study of processes to produce parts and assemble them. Metal casting involves pouring molten metal into a mold to make components. The key steps are pattern making, mold preparation using sand, and gating systems to pour the molten metal. Casting is used to make components for various industries like automotive, machinery, defense, and household appliances.

METAL CASTING PROCESSES

This document discusses metal casting processes and patterns used in sand mold casting. It provides information on the basic steps of the casting process, including melting metal, pouring it into a mold, allowing it to solidify, and removing the casting. It classifies casting processes and describes sand mold casting in detail. This includes the use of patterns to form cavities in molds, common pattern materials like wood and metal, and different types of patterns such as single-piece, two-piece, loose-piece, and multi-piece patterns. Gating systems and cores are also discussed.

Unit 1 manufacturing technology I Metal casting process

This document discusses various metal casting processes and techniques. It covers topics like sand casting, pattern making, molding sand properties, core making, and casting defects. Sand casting involves pouring molten metal into an expandable sand mold and allowing it to solidify. Different types of sand and patterns are used depending on the application. Properties of molding sand like permeability and strength are important. Cores are used to create internal cavities and angles in castings.

Recommended

Manufacturing technology unit 1(CASTING)

casting introduction, steps involved in casting,gating system,gates,pattern, patterns allowances, advantages and disadvantages of casting process and applications of casting process

Unit 1-METAL CASTING PROCESSES

1. The document discusses various metal casting processes and sand casting in particular. It describes the basic steps in sand casting including mould making, pouring, cooling, and removal.

2. Sand is commonly used as the mould material due to its low cost. It requires binders like clay to give it strength and hold its shape. The properties of ideal moulding sand and types of sands for different applications are explained.

3. Key aspects of sand casting like advantages, disadvantages, and factors affecting the properties of moulding sand are summarized. Common tests to evaluate moulding sand quality are also mentioned.

MANUFACTURING TECHNOLOGY-I

The document discusses manufacturing processes and sand casting. It defines manufacturing as making goods by hand or machinery. Manufacturing processes are classified into casting, joining, forming, sheet metal work, plastics processing, machining, powder metallurgy, heat treatment, and assembly. Sand casting is described as producing metal parts by pouring molten metal into sand molds. Molds are made using patterns, cores, and molding machines in a foundry. Sand casting can make complex shapes and is used to produce parts in large quantities.

Metal casting ppt1

Metal casting processes involve making a mold cavity using a pattern, melting and pouring metal into the mold, and allowing the metal to solidify. Key steps include preparing molds, melting and pouring metal, solidification, and inspection. Casting allows intricate shapes and wide material selection. Advantages are dimensional accuracy and surface finish can be limitations but new processes address these. Patterns are models of the final casting and come in various types depending on shape, size, and molding method. Careful pattern preparation helps minimize defects in the final casting.

MANUFACTURING TECHNOLOGY-I

The document discusses metal casting processes. It provides an overview of casting technology and classifications of solidification processes. Specifically, it describes sand casting processes including mold materials, open and closed molds, gating systems, risers, heating metal, pouring, and solidification of pure metals and alloys. Sand casting involves using expendable molds made of sand to form a cavity that shapes molten metal.

Casting process

The document discusses manufacturing technology and metal casting processes. It defines manufacturing as making goods by hand or machinery. Manufacturing technology is the study of processes to produce parts and assemble them. Metal casting involves pouring molten metal into a mold to make components. The key steps are pattern making, mold preparation using sand, and gating systems to pour the molten metal. Casting is used to make components for various industries like automotive, machinery, defense, and household appliances.

METAL CASTING PROCESSES

This document discusses metal casting processes and patterns used in sand mold casting. It provides information on the basic steps of the casting process, including melting metal, pouring it into a mold, allowing it to solidify, and removing the casting. It classifies casting processes and describes sand mold casting in detail. This includes the use of patterns to form cavities in molds, common pattern materials like wood and metal, and different types of patterns such as single-piece, two-piece, loose-piece, and multi-piece patterns. Gating systems and cores are also discussed.

Unit 1 manufacturing technology I Metal casting process

This document discusses various metal casting processes and techniques. It covers topics like sand casting, pattern making, molding sand properties, core making, and casting defects. Sand casting involves pouring molten metal into an expandable sand mold and allowing it to solidify. Different types of sand and patterns are used depending on the application. Properties of molding sand like permeability and strength are important. Cores are used to create internal cavities and angles in castings.

Metal casting process

Metal casting involves pouring liquid metal into a mold to produce parts of a desired shape. The key steps are melting metal to create a liquid, pouring it into a mold to achieve a solid shape as it cools and extracts heat, and then removing the solidified part from the mold. The quality of castings depends on factors like the flow of molten metal into the mold, the solidification and cooling process, and the type of mold material used. Common casting methods include sand casting, die casting, and investment casting.

Mp (casting)

each concept is explained in brief. starting from very basics coming to practical applications followed by its operations, pattern making and defects

Introduction to Casting

This document provides an introduction to casting processes. It discusses the basic steps involved, which include pouring molten metal into a refractory mold to take on its shape upon solidification. Different types of casting processes are classified, including sand casting where a sand mold is used. Patterns, properties of molding sand, and common molding techniques like bench, floor, pit and machine molding are also overviewed. Key advantages of casting include the ability to produce complex shapes from various metals in small or large quantities.

Casting process

Casting is a process where molten metal is poured into a mold and solidifies to form the desired shape. There are two main types of casting processes - those using expendable molds like sand, and those using permanent metal molds. The mold contains the cavity that defines the external shape of the part as well as any internal cores. Direction solidification is important to prevent shrinkage defects and is controlled using features like risers and chills. Properties of the final part are dependent on factors like alloy composition and solidification rate.

Manufacturing Technology unit 1

This document summarizes various metal casting processes and techniques. It discusses sand casting and the key components of sand molds like the flask, pouring basin, sprue, runners, and risers. It also covers cores, moulding sands, patterns, moulding machines, melting furnaces, and common defects in sand casting. Testing methods for moulding sands like moisture content, clay content, and permeability are also summarized.

3.expendable mold casting

The document discusses various metal casting processes that use expendable molds. It describes sand casting as the most common casting method, where a sand mixture is packed around a pattern and then melted metal is poured in. Different types of patterns are discussed, including one-piece, split, match plate, and cope and drag patterns. The key molding sand ingredients and their properties are also summarized.

Metal Casting - Manufacturing Technology 1

The document discusses manufacturing technology and focuses on sand casting. It defines key terms like manufacturing, technology, and manufacturing technology. It then discusses the history and process of metal casting. The main focus is on sand casting, including its definition, the 6 step process, and types like green sand and dry sand. Pattern materials and allowances are explained. Finally, it touches on moulding sand constituents, properties, core making, and sand testing methods.

Unit 1 casting processes

THIS STUDY MATERIAL IS RELATED WITH ONE OF THE TYPE OF MANUFACTURING PROCESSES CALLED CASTING.THIS IS VERY GOOD MATERIAL . CASTING IS BASIC MANUFACTURING PROCESS.EVERY MECHANICAL ENGINEERING STUDENT MUST KNOW CASTING PROCESS,ITS TYPES ,PATTERN ,PATTERN TYPES,PATTERN MAKING ALLOWANCES,DIE CASTING INVESTMENT CASTING.ALL THESE POINTS ARE COVERED IN THIS PPT.

Casting of metals and alloys

Casting is a manufacturing process where liquid material is poured into a mold and solidifies. Advantages include low cost for complex parts and reduced weight. Vacancies in casting include shortage of skilled technicians and need for more capable simulation software. Simulation software allows for predicting cast structure, properties, defects and reducing costs. Aluminum and magnesium alloys are increasingly used in automotive parts like suspension parts and dashboards. New developments in casting include squeeze casting and lost foam casting. Shell molding uses sand and resin to form thin shells. Counter gravity casting and differential pressure casting produce parts like camshafts and crankcases. Flaskless molding avoids flask transport and repair. Freeze casting forms ice patterns for casting. Semisolid

TYPES of moulding processes used in casting-MP2

- There are four main types of moulding used in casting processes: floor moulding, bench moulding, pit moulding, and machine moulding. Floor and pit moulding are used for large heavy castings, bench moulding for smaller light items, and machine moulding for mass production.

- The main moulding sands used are green sand, dry sand, loam sand, and core sand, which differ in their mixture proportions and required drying. Green sand moulding is most common and adaptable but provides lower strength.

- Other moulding methods include shell moulding, which produces molds from resin-bonded sand in two halves

Full Mould Casting Process

Full mould casting is a casting process that uses an expanded polystyrene foam pattern surrounded by sand. Molten metal is poured directly into the mould, vaporizing the foam and allowing the metal to fill the entire mould cavity. This process is similar to lost wax casting but uses a thermally decomposable foam pattern instead of wax. The foam pattern can be designed using computer tools before the casting process. Some advantages are it is cheaper than investment casting, requires no drafts or risers, and has good dimensional accuracy and surface finish.

CASTING PPT

The document discusses the casting process. It begins by describing how a liquid material is poured into a mold cavity to take its shape, then solidifies. This allows for complex geometries and net-shape production. Casting can be done with any material that melts and is suited for mass production. Common casting defects and their causes are also outlined.

Expendable mould processes

Shell molding uses a sand shell held together with a thermosetting resin as the mold cavity. The process involves heating a metal pattern and pressing it into a sand mixture to form a shell, which is then cured, stripped, and the two shell halves are assembled for pouring. Vacuum molding is a counter gravity process where molten metal is drawn into a sand mold cavity under low pressure vacuum. Investment casting uses a wax pattern surrounded by refractory material to form the mold, the wax is then melted out before pouring the molten metal.

Metal casting process

Metal casting involves pouring liquid metal into a mold to produce parts of a desired shape. The key steps are melting metal to create a liquid, pouring it into a mold to achieve a solid shape as it cools and extracts heat, and then removing the solidified part from the mold. The quality of castings depends on factors like the flow of molten metal into the mold, the solidification and cooling process, and the type of mold material used. Common casting methods include sand casting, die casting, and investment casting.

Casting process

This document provides information on the manufacturing process of metal casting. It discusses the key steps in metal casting which include mould preparation, pouring molten metal, solidification, and inspection for defects. Moulds are prepared using sand and patterns to form cavities. Molten metal is poured into the mould and allowed to solidify to form the final casting. Proper mould design and avoiding defects are important for successful casting. Metal casting allows for intricate shapes but has limitations in dimensional accuracy and surface finish compared to other processes.

Casting by amjad

The document describes the steps involved in the sand casting process. It begins by making a pattern from materials like wood, metal, or plastic. Sand mixtures are then prepared for molding and cores. The mold and cores are formed using the pattern. Metal is melted and poured into the mold, where it solidifies into a casting. The casting is then cleaned, inspected for defects, heat treated, and inspected again before shipping. Various types of patterns, materials for patterns, and allowances made on patterns are also described.

Casting unit 1 notes

This document provides an overview of casting processes and patterns used in manufacturing. It discusses various types of foundries based on production levels. Patterns are models used to form mold cavities and can be made from various materials like wood, metal, and plastic. Allowances must be provided in patterns to account for shrinkage, draft, machining needs, and potential distortions during solidification. Different types of patterns are used depending on the part geometry, including single-piece, split, gated, sweep, and skeleton patterns.

Hari ppt

Metal casting involves pouring molten metal into a mold cavity to solidify into the desired shape, with common mold materials including sand. The main steps are making patterns and molds, melting metal, pouring into the mold, solidification, and finishing. Key casting methods include green sand molding, shell molding, and die casting which offer advantages like complexity of parts and better dimensional accuracy and surface finish compared to sand casting.

Core type and applications (1.2)

The document discusses the key characteristics and preparation methods for core sands used in metal casting. Core sands must have strength, permeability, thermal stability, and collapsibility. They are prepared using silica sand and can be bonded with sodium silicate, oil, or resin. Cores can be produced through green sand, dry sand, or hardened processes like CO2 or hot box. Common core types include horizontal, vertical, cover, balanced, drop, and kiss cores which are positioned differently in the mold. Core boxes are used to form cores and come in various styles.

Founding and Casting

The document describes the foundry processes at Porwal Auto Components Ltd. It discusses their facilities for casting, molding, melting, and testing. The company manufactures automotive and earthmoving parts using sand casting and cold box molding processes. Equipment includes induction furnaces, molding machines, sand plants, and testing facilities for chemical analysis, hardness testing, and non-destructive testing of castings.

Unit i

The document discusses various metal casting processes and techniques. It covers topics like sand casting, pattern making, moulding sand, cores, melting furnaces, and special casting processes. Sand casting is introduced as one of the most common casting methods where a sand mould is used. Different types of patterns and allowances are described. The properties and testing of moulding sands like green sand and dry sand are outlined. Special casting techniques like shell mould casting and investment casting that use non-sand moulds are also summarized briefly.

MANUFACTURING PROCESS-I

Sand casting is a process for producing metal parts by pouring molten metal into a sand mould cavity of the required shape. Patterns are used to form the cavity and are made of materials like wood, metal or plastic. Moulding sand properties like permeability and strength are tested. Molten metal is produced using furnaces like cupola or crucible furnaces. Special casting processes include shell mould casting, investment casting, pressure die casting and centrifugal casting. Cores are also produced to create internal features in castings.

More Related Content

What's hot

Metal casting process

Metal casting involves pouring liquid metal into a mold to produce parts of a desired shape. The key steps are melting metal to create a liquid, pouring it into a mold to achieve a solid shape as it cools and extracts heat, and then removing the solidified part from the mold. The quality of castings depends on factors like the flow of molten metal into the mold, the solidification and cooling process, and the type of mold material used. Common casting methods include sand casting, die casting, and investment casting.

Mp (casting)

each concept is explained in brief. starting from very basics coming to practical applications followed by its operations, pattern making and defects

Introduction to Casting

This document provides an introduction to casting processes. It discusses the basic steps involved, which include pouring molten metal into a refractory mold to take on its shape upon solidification. Different types of casting processes are classified, including sand casting where a sand mold is used. Patterns, properties of molding sand, and common molding techniques like bench, floor, pit and machine molding are also overviewed. Key advantages of casting include the ability to produce complex shapes from various metals in small or large quantities.

Casting process

Casting is a process where molten metal is poured into a mold and solidifies to form the desired shape. There are two main types of casting processes - those using expendable molds like sand, and those using permanent metal molds. The mold contains the cavity that defines the external shape of the part as well as any internal cores. Direction solidification is important to prevent shrinkage defects and is controlled using features like risers and chills. Properties of the final part are dependent on factors like alloy composition and solidification rate.

Manufacturing Technology unit 1

This document summarizes various metal casting processes and techniques. It discusses sand casting and the key components of sand molds like the flask, pouring basin, sprue, runners, and risers. It also covers cores, moulding sands, patterns, moulding machines, melting furnaces, and common defects in sand casting. Testing methods for moulding sands like moisture content, clay content, and permeability are also summarized.

3.expendable mold casting

The document discusses various metal casting processes that use expendable molds. It describes sand casting as the most common casting method, where a sand mixture is packed around a pattern and then melted metal is poured in. Different types of patterns are discussed, including one-piece, split, match plate, and cope and drag patterns. The key molding sand ingredients and their properties are also summarized.

Metal Casting - Manufacturing Technology 1

The document discusses manufacturing technology and focuses on sand casting. It defines key terms like manufacturing, technology, and manufacturing technology. It then discusses the history and process of metal casting. The main focus is on sand casting, including its definition, the 6 step process, and types like green sand and dry sand. Pattern materials and allowances are explained. Finally, it touches on moulding sand constituents, properties, core making, and sand testing methods.

Unit 1 casting processes

THIS STUDY MATERIAL IS RELATED WITH ONE OF THE TYPE OF MANUFACTURING PROCESSES CALLED CASTING.THIS IS VERY GOOD MATERIAL . CASTING IS BASIC MANUFACTURING PROCESS.EVERY MECHANICAL ENGINEERING STUDENT MUST KNOW CASTING PROCESS,ITS TYPES ,PATTERN ,PATTERN TYPES,PATTERN MAKING ALLOWANCES,DIE CASTING INVESTMENT CASTING.ALL THESE POINTS ARE COVERED IN THIS PPT.

Casting of metals and alloys

Casting is a manufacturing process where liquid material is poured into a mold and solidifies. Advantages include low cost for complex parts and reduced weight. Vacancies in casting include shortage of skilled technicians and need for more capable simulation software. Simulation software allows for predicting cast structure, properties, defects and reducing costs. Aluminum and magnesium alloys are increasingly used in automotive parts like suspension parts and dashboards. New developments in casting include squeeze casting and lost foam casting. Shell molding uses sand and resin to form thin shells. Counter gravity casting and differential pressure casting produce parts like camshafts and crankcases. Flaskless molding avoids flask transport and repair. Freeze casting forms ice patterns for casting. Semisolid

TYPES of moulding processes used in casting-MP2

- There are four main types of moulding used in casting processes: floor moulding, bench moulding, pit moulding, and machine moulding. Floor and pit moulding are used for large heavy castings, bench moulding for smaller light items, and machine moulding for mass production.

- The main moulding sands used are green sand, dry sand, loam sand, and core sand, which differ in their mixture proportions and required drying. Green sand moulding is most common and adaptable but provides lower strength.

- Other moulding methods include shell moulding, which produces molds from resin-bonded sand in two halves

Full Mould Casting Process

Full mould casting is a casting process that uses an expanded polystyrene foam pattern surrounded by sand. Molten metal is poured directly into the mould, vaporizing the foam and allowing the metal to fill the entire mould cavity. This process is similar to lost wax casting but uses a thermally decomposable foam pattern instead of wax. The foam pattern can be designed using computer tools before the casting process. Some advantages are it is cheaper than investment casting, requires no drafts or risers, and has good dimensional accuracy and surface finish.

CASTING PPT

The document discusses the casting process. It begins by describing how a liquid material is poured into a mold cavity to take its shape, then solidifies. This allows for complex geometries and net-shape production. Casting can be done with any material that melts and is suited for mass production. Common casting defects and their causes are also outlined.

Expendable mould processes

Shell molding uses a sand shell held together with a thermosetting resin as the mold cavity. The process involves heating a metal pattern and pressing it into a sand mixture to form a shell, which is then cured, stripped, and the two shell halves are assembled for pouring. Vacuum molding is a counter gravity process where molten metal is drawn into a sand mold cavity under low pressure vacuum. Investment casting uses a wax pattern surrounded by refractory material to form the mold, the wax is then melted out before pouring the molten metal.

Metal casting process

Metal casting involves pouring liquid metal into a mold to produce parts of a desired shape. The key steps are melting metal to create a liquid, pouring it into a mold to achieve a solid shape as it cools and extracts heat, and then removing the solidified part from the mold. The quality of castings depends on factors like the flow of molten metal into the mold, the solidification and cooling process, and the type of mold material used. Common casting methods include sand casting, die casting, and investment casting.

Casting process

This document provides information on the manufacturing process of metal casting. It discusses the key steps in metal casting which include mould preparation, pouring molten metal, solidification, and inspection for defects. Moulds are prepared using sand and patterns to form cavities. Molten metal is poured into the mould and allowed to solidify to form the final casting. Proper mould design and avoiding defects are important for successful casting. Metal casting allows for intricate shapes but has limitations in dimensional accuracy and surface finish compared to other processes.

Casting by amjad

The document describes the steps involved in the sand casting process. It begins by making a pattern from materials like wood, metal, or plastic. Sand mixtures are then prepared for molding and cores. The mold and cores are formed using the pattern. Metal is melted and poured into the mold, where it solidifies into a casting. The casting is then cleaned, inspected for defects, heat treated, and inspected again before shipping. Various types of patterns, materials for patterns, and allowances made on patterns are also described.

Casting unit 1 notes

This document provides an overview of casting processes and patterns used in manufacturing. It discusses various types of foundries based on production levels. Patterns are models used to form mold cavities and can be made from various materials like wood, metal, and plastic. Allowances must be provided in patterns to account for shrinkage, draft, machining needs, and potential distortions during solidification. Different types of patterns are used depending on the part geometry, including single-piece, split, gated, sweep, and skeleton patterns.

Hari ppt

Metal casting involves pouring molten metal into a mold cavity to solidify into the desired shape, with common mold materials including sand. The main steps are making patterns and molds, melting metal, pouring into the mold, solidification, and finishing. Key casting methods include green sand molding, shell molding, and die casting which offer advantages like complexity of parts and better dimensional accuracy and surface finish compared to sand casting.

Core type and applications (1.2)

The document discusses the key characteristics and preparation methods for core sands used in metal casting. Core sands must have strength, permeability, thermal stability, and collapsibility. They are prepared using silica sand and can be bonded with sodium silicate, oil, or resin. Cores can be produced through green sand, dry sand, or hardened processes like CO2 or hot box. Common core types include horizontal, vertical, cover, balanced, drop, and kiss cores which are positioned differently in the mold. Core boxes are used to form cores and come in various styles.

Founding and Casting

The document describes the foundry processes at Porwal Auto Components Ltd. It discusses their facilities for casting, molding, melting, and testing. The company manufactures automotive and earthmoving parts using sand casting and cold box molding processes. Equipment includes induction furnaces, molding machines, sand plants, and testing facilities for chemical analysis, hardness testing, and non-destructive testing of castings.

What's hot (20)

Similar to Metal casting processes

Unit i

The document discusses various metal casting processes and techniques. It covers topics like sand casting, pattern making, moulding sand, cores, melting furnaces, and special casting processes. Sand casting is introduced as one of the most common casting methods where a sand mould is used. Different types of patterns and allowances are described. The properties and testing of moulding sands like green sand and dry sand are outlined. Special casting techniques like shell mould casting and investment casting that use non-sand moulds are also summarized briefly.

MANUFACTURING PROCESS-I

Sand casting is a process for producing metal parts by pouring molten metal into a sand mould cavity of the required shape. Patterns are used to form the cavity and are made of materials like wood, metal or plastic. Moulding sand properties like permeability and strength are tested. Molten metal is produced using furnaces like cupola or crucible furnaces. Special casting processes include shell mould casting, investment casting, pressure die casting and centrifugal casting. Cores are also produced to create internal features in castings.

UNIT - I.ppt

Sand casting is a process for producing metal parts by pouring molten metal into a sand mould cavity of the required shape. Patterns are used to form the cavity and are made from materials like wood, metal, or plastic. Moulding sand properties like permeability and strength are tested. Molten metal is produced using furnaces like cupolas or crucibles. Special casting processes include shell moulding, investment casting, die casting, and centrifugal casting. Cores are also used inside the mould cavity.

MANUFACTURING TECHNOLOGY-I

Sand casting is a process for producing metal parts by pouring molten metal into a sand mould cavity of the required shape. Patterns are used to form the cavity and are made from materials like wood, metal or plastic. Moulding sand properties like permeability and strength are tested. Molten metal is produced using furnaces like cupolas or crucibles. Special casting processes include shell moulding, investment casting, die casting and centrifugal casting. Cores are also used to create internal features and are made from mixtures of sand and binders.

METAL CASTING PROCESSES

Sand casting is a process for producing metal parts by pouring molten metal into a sand mould cavity. Key steps include making patterns to form the mould cavity, using various types of sand like green sand with moisture and clay, and testing properties of moulding sand. Special casting processes include shell mould casting, investment casting and lost wax process. Castings are inspected using visual, magnetic particle, dye penetrant and ultrasonic methods to find internal and surface defects.

METAL CASTING PROCESSES

This document provides an overview of sand casting processes. It discusses the key steps which include pattern making, molding sand properties and testing, core making, melting furnaces, casting defects and inspection methods. The main molding processes covered are green sand molding and dry sand molding. Common casting defects like blowholes and surface cracks are addressed. Non-destructive testing methods for inspecting castings such as magnetic particle, dye penetrant, radiography and ultrasonic testing are also summarized.

Unit i METAL CASTING PROCESSES

Sand casting is a process used to produce metal parts by pouring molten metal into a sand mould cavity. Key steps include making patterns, preparing moulding sand with specific properties, and testing the sand. Common casting defects can be inspected using visual, magnetic particle, dye penetrant, radiographic, ultrasonic, or thermography methods. Special casting processes exist like shell mould casting, investment casting, lost wax process, and die casting.

casting process ( MP 2 / SEM 4 / GTU )

The document discusses the various steps involved in the casting process including making patterns and cores, making molds, melting and pouring metal, and finishing processes. It describes different types of patterns such as loose patterns, gated patterns, and cope and drag patterns. It also discusses various molding methods like green sand molding, dry sand molding, and loam sand molding. Key mold properties like strength, permeability, and refractory nature are explained. Methods of testing mold properties like clay content, moisture content, and permeability are also summarized.

Sand Casting

This document discusses sand casting and provides details on:

- The types of casting sand including green sand, water glass sand, and resin sand.

- The key properties of casting sand such as strength, permeability, grain size, thermal stability, and reusability.

- Common casting defects related to issues with the sand mold like sand blow, pinholes, and sand wash.

- How to test sand properties including measuring moisture content, clay content, and grain size distribution.

ME8351 Unit 1 class notes- Pattern

This document provides information on metal casting processes and patterns. It discusses the different types of patterns used such as single piece patterns, shell patterns, and wax patterns. It also covers the various pattern allowances including shrinkage allowance, machining allowance, draft allowance, and others. The document discusses the properties and types of molding sands used including green sand, dry sand, facing sand, loam sand, backing sand, parting sand and core sand. It provides details on the requirements for molding materials including refractoriness, permeability, green strength and others.

Unit1 Metal Casting Processes (2).ppt

This document provides an overview of various manufacturing processes, with a focus on metal casting processes. It discusses the steps in metal casting including creating a mould, pouring molten metal, and removing the casting. It describes important casting products and the advantages and limitations of casting. Key terms related to casting like pattern, parting line, and riser are defined. Different pattern materials and allowances are also covered. Moulding materials like green sand and core sand are explained. Finally, other metal forming processes like die casting are introduced.

Unit 1- MCS.pptx

This document discusses the properties and composition of molding materials used in metal casting. It outlines 11 key properties molding materials must have including refractoriness, permeability, green strength, dry strength, and collapsibility. Common molding materials are described as sand, with silica sand being most widely used. The composition of molding sand is outlined as consisting of a base sand like silica, a binder like clay, and moisture. Factors that affect mold quality like moisture content, grain size, and shape are also summarized.

Metal casting ppt2

This document discusses various metal casting processes and their characteristics. It describes four main categories of casting processes: conventional moulding, chemical sand moulding, permanent mould processes, and special casting processes. Green sand moulding is the most common conventional process and uses sand mixed with clay as the mould material. Dry sand moulding bakes the mould to increase strength. Shell moulding uses a resin-bound sand mould only a few millimeters thick to provide a smooth surface finish. Investment casting allows for intricate parts by coating a wax pattern in refractory material before melting away the wax.

Steps involved in sand casting process

The document discusses the process of sand casting. It describes the key steps which include preparing the mould and molten metal, pouring the molten metal into the mould, solidification, and removing the cast part. Several types of patterns are discussed along with their materials and uses. The document also covers moulding sand properties and testing methods. Common defects in castings are described. The overall document provides details on the sand casting manufacturing process.

Casting Processes

This ppt consists of all casting processes and types of casting defect in casting and Basic component of casting process

Casting

This document discusses various casting processes and related topics. It begins with definitions of casting and different casting processes like permanent mold casting, investment casting, centrifugal casting, continuous casting, and sand casting. For each process, it provides details on the process, applications, advantages and limitations. It also discusses topics like molding sands, furnaces used in foundries like cupolas, electric arc furnaces, and induction furnaces. The document aims to provide an overview of casting processes and technologies.

Lecture 2 casting full

This document provides information on the casting process, including definitions, components, steps, and considerations. Some key points:

1. The casting process involves pouring molten metal into a mold patterned after the part, allowing it to solidify, and removing the part from the mold. Important considerations are metal flow, solidification, and mold material.

2. Components include patterns, molds, cores, and gating systems. Steps are pattern making, molding, melting, pouring, solidification, cleaning, and inspection.

3. Patterns are modified replicas of the object and include allowances for shrinkage, draft, and machining. Common pattern materials are wood, metal, and plastic

Pratipt S. Pareek K11077

1. The document discusses the ingredients and components used in the moulding process for casting metals. It describes the key materials like sand, clay, moisture and their properties.

2. The moulding process involves making a cavity in sand using a pattern, incorporating the pattern in a gating system, removing the pattern, pouring molten metal, allowing it to cool, and removing the casting.

3. The advantages of the moulding process are its reusability, good dimensional accuracy, and high production rates compared to other casting methods. Typical tolerances and surface finishes are provided.

Cement industry

This document provides an overview of the cement industry, including the raw materials, manufacturing process, applications, and advantages and disadvantages of cement. It discusses the key raw materials used like limestone and clay. The manufacturing process involves crushing, mixing, heating in a kiln to form clinkers, grinding the clinkers with gypsum. Cement is used widely in construction for applications like concrete, mortar, roads. It has advantages of durability, fire resistance but can crack and has low tensile strength.

moulding shop.pptx

This document provides information on moulding processes and materials used in a foundry workshop. It discusses the different types of metals used in casting like ferrous, non-ferrous, and alloy metals. It also describes the various types of sand used for moulding like green sand, dry sand, facing sand, parting sand, and core sand. The document outlines the tools and equipment used in moulding like moulding boxes, rammers, riddles, and patterns. It also explains the steps involved in mould making, melting metals, fitting castings, and inspecting the final products.

Similar to Metal casting processes (20)

More from Muthukumar V

HEAT TREATMENT

Heat treatment involves heating and cooling of metals to obtain desired properties. Common heat treatment processes include annealing, normalizing, and hardening. Quenching involves rapidly cooling heated steel to make it harder and stronger. Case hardening processes like carburizing add carbon to the surface of low-carbon steel to create a hard outer case. Induction and flame hardening are surface hardening techniques used for gears, shafts and other rotating components. Time-temperature transformation and continuous cooling transformation diagrams are used to determine the microstructures that form during heat treating processes.

NON-METALLIC MATERIALS

This document provides an overview of non-metallic materials including polymers, ceramics, and composites. It discusses key polymer types like polyethylene, polypropylene, polystyrene, polyvinyl chloride, and nylon. It describes their properties, production processes, and common applications. Terminology used in polymers like monomer, polymer, polymerization, homopolymer, and copolymer are also defined. The different types of polymerization and various polymer classifications are outlined.

TESTING OF MECHANICAL PROPERTIES

This document provides information on various mechanical tests conducted to evaluate properties of materials, including:

- Plastic deformation testing which evaluates a material's ability to deform permanently under load.

- Hardness testing methods like Brinell, Vickers, and Rockwell which indent materials with an indenter to assess hardness.

- Impact testing like Izod and Charpy tests which determine a material's resistance to sudden load by measuring how much energy is absorbed during fracture.

- Fatigue and creep testing which apply repeated or sustained loads to examine how materials withstand cyclic stresses or deformation over time.

A variety of destructive and non-destructive tests are described that are used industrially and for research to

FERROUS AND NON FERROUS METALS

- Steels are alloys of iron and carbon, with other common alloying elements including manganese, silicon, sulfur, and phosphorus.

- Carbon content determines the type of steel - low carbon (<0.35%) is mild steel, medium carbon (0.35-0.55%) is harder, and high carbon (0.55-1.55%) responds to heat treatment.

- Alloying elements like chromium, nickel, molybdenum increase properties like corrosion resistance, strength, and high temperature performance. Stainless steels contain a minimum of 10.5% chromium.

CONSTITUTION OF ALLOYS

1. Alloys are made of two or more metals to obtain desired properties like strength, toughness, corrosion resistance that pure metals lack.

2. A solid solution is a homogeneous mixture of atoms where solute atoms substitute or fit in the lattice structure of the solvent metal.

3. Cooling curves and phase diagrams are used to understand the solidification process of alloys and predict the phases present at various temperatures and compositions.

UNIT-II---FEA

A beam is a structural member that is supported along its length and subjected to external forces acting perpendicular to its central axis. There are different types of beams including cantilever, simply supported, overhanging, fixed, and continuous beams. Beams can experience different types of transverse loading such as point loads, uniformly distributed loads, and uniformly varying loads.

UNIT-IV-- FEA

This document discusses axisymmetric elements for finite element analysis. It covers the conditions required for a problem to be axisymmetric, including symmetry about the axis of revolution. It also discusses the derivation of shape functions for axisymmetric elements, including a three node axisymmetric triangular element. Finally, it mentions assembling the element stiffness matrix and calculating stresses and strains.

Unit-III---FEA

The Linear Strain Triangular (LST) element is a six noded triangular element that has 12 unknown displacement degrees of freedom. It can be used for finite element analysis of structures and materials. The LST element approximates strains and displacements using linear interpolation between its six nodes.

Unit-I--FEA

This document discusses the finite element method (FEM) for numerical analysis of engineering problems. It describes the general steps of FEM which include discretizing the domain into simple geometric elements, choosing interpolation functions, deriving the element stiffness matrices, assembling the matrices into a global system, applying boundary conditions, and solving for displacements/stresses. FEM allows for approximate solutions of complex problems involving various material properties, geometries, and loading conditions.

Unit 5--FEA

The document discusses the benefits of exercise for mental health. Regular physical activity can help reduce anxiety and depression and improve mood and cognitive functioning. Exercise boosts blood flow, releases endorphins, and promotes changes in the brain which help enhance one's emotional well-being and mental clarity.

Robotics - Unit-II

The document discusses various types of robot drive systems and end effectors. It describes hydraulic, pneumatic, and electric drive systems. Hydraulic drives use pressurized fluid and are suitable for heavy loads. Pneumatic drives use compressed air and are cheaper but generate more noise. Electric drives include AC servo motors, DC servo motors, and stepper motors. Stepper motors convert electrical pulses to rotational movement precisely. Servo motors are used in automatic control systems. The document also discusses actuators, motors, and end effectors like grippers used by robots.

Unit-V---Implementation of Robot

This document discusses material handling and various types of equipment used for moving materials within production environments, including automated guided vehicles (AGVs). It describes rail guided vehicles (RGVs) which use transportation rails to move multiple vehicles according to requirements. The document outlines different types of AGV navigation systems including laser target navigation and obstacle detection. It also discusses AGV control systems and batteries used to power AGVs. Laser guided vehicles are introduced which use laser scanners and targets for accurate positioning and guidance of material handling robots.

Economic analysis of robot

This document discusses different types of economic analysis used to evaluate robots, including cost effectiveness analysis, cost benefit analysis, and economic impact analysis. It describes return on investment (ROI) as a method that measures gains or losses from an investment relative to the amount invested. The document also explains that cash flow analysis evaluates a company's cash inflows and outflows from operations, financing, and investing to carefully manage cash flow.

UNIT-IV-- Robotics

The document discusses robot kinematics and robot programming. It covers topics like forward and inverse kinematics, Jacobian matrices, and manipulator dynamics. It also discusses trajectory generation and manipulator mechanism design. Finally, it discusses robot programming languages like VAL and how they are used to program motion commands, sensor commands, end effector commands, and simple programs.

Unit III-- senors in robotics

The document discusses various types of sensors and machine vision systems. It describes position sensors including piezoelectric sensors, LVDTs, optical encoders, and resolvers. It also covers range sensors, touch sensors, cameras, and image processing techniques. The key applications mentioned are inspection, identification, visual serving, and navigation.

Unit-2-- End effector

The document discusses various types of robot end effectors and grippers. It describes grippers classified based on the method used to hold objects like mechanical, vacuum, magnetic, etc. It also discusses gripper mechanisms, actuation methods, and factors to consider for gripper design and selection. The key types covered are mechanical, vacuum, magnetic, pneumatic, and hydraulic grippers.

Unit-I Robotics

This document provides an overview of robot fundamentals, including definitions, classifications, specifications, anatomy, and applications. It defines a robot as a reprogrammable mechanical device that performs tasks controlled by a human or automated system. Robots are classified based on their mechanical arm, degrees of freedom, power source, control system, sensors, movement, industry application and more. The document also describes common robot coordinate systems, joints, motions, and specifications for different robot configurations including Cartesian, cylindrical, polar, SCARA and more. It provides examples of various robot applications in industries.

Planning

The document discusses various aspects of planning including defining goals and strategies, types of plans such as strategic and operational, and the planning process. It also covers management by objectives (MBO) which involves employees and managers jointly determining goals and reviewing progress. Additional topics include objectives and their characteristics, contingency factors in planning like environmental uncertainty, and decision making under different conditions.

Overview of management

This document provides an overview of principles of management. It discusses key concepts such as organizations, goals, and the role of management. It also examines the four functions of management: planning, organizing, leading, and controlling. Additionally, it covers topics like management levels, managerial skills and responsibilities, and historical perspectives on the evolution of management thought, including scientific management and administrative management.

Cast iron

This document discusses different types of cast irons and their properties. It begins by describing the composition of cast iron which contains more than 2% carbon along with alloying elements like silicon, sulfur, manganese, and phosphorus. The main types discussed are grey cast iron, which is the most widely used due to its low cost; white cast iron, which is very hard and brittle; malleable cast iron, which is made by heat treating white cast iron to improve ductility; and spheroidal graphite cast iron, which has improved ductility from nodular graphite formation. The document also covers how alloying elements and heat treatments can impact the microstructure and properties of cast irons.

More from Muthukumar V (20)

Recently uploaded

bank management system in java and mysql report1.pdf

truth is high but higher still is truth full living

ACEP Magazine edition 4th launched on 05.06.2024

This document provides information about the third edition of the magazine "Sthapatya" published by the Association of Civil Engineers (Practicing) Aurangabad. It includes messages from current and past presidents of ACEP, memories and photos from past ACEP events, information on life time achievement awards given by ACEP, and a technical article on concrete maintenance, repairs and strengthening. The document highlights activities of ACEP and provides a technical educational article for members.

[JPP-1] - (JEE 3.0) - Kinematics 1D - 14th May..pdf![[JPP-1] - (JEE 3.0) - Kinematics 1D - 14th May..pdf](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![[JPP-1] - (JEE 3.0) - Kinematics 1D - 14th May..pdf](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

Kinematics 11th jpp- 01. ( Solved ) unacademy namo kaul on 14th may...

Recycled Concrete Aggregate in Construction Part III

Using recycled concrete aggregates (RCA) for pavements is crucial to achieving sustainability. Implementing RCA for new pavement can minimize carbon footprint, conserve natural resources, reduce harmful emissions, and lower life cycle costs. Compared to natural aggregate (NA), RCA pavement has fewer comprehensive studies and sustainability assessments.

DEEP LEARNING FOR SMART GRID INTRUSION DETECTION: A HYBRID CNN-LSTM-BASED MODEL

As digital technology becomes more deeply embedded in power systems, protecting the communication

networks of Smart Grids (SG) has emerged as a critical concern. Distributed Network Protocol 3 (DNP3)

represents a multi-tiered application layer protocol extensively utilized in Supervisory Control and Data

Acquisition (SCADA)-based smart grids to facilitate real-time data gathering and control functionalities.

Robust Intrusion Detection Systems (IDS) are necessary for early threat detection and mitigation because

of the interconnection of these networks, which makes them vulnerable to a variety of cyberattacks. To

solve this issue, this paper develops a hybrid Deep Learning (DL) model specifically designed for intrusion

detection in smart grids. The proposed approach is a combination of the Convolutional Neural Network

(CNN) and the Long-Short-Term Memory algorithms (LSTM). We employed a recent intrusion detection

dataset (DNP3), which focuses on unauthorized commands and Denial of Service (DoS) cyberattacks, to

train and test our model. The results of our experiments show that our CNN-LSTM method is much better

at finding smart grid intrusions than other deep learning algorithms used for classification. In addition,

our proposed approach improves accuracy, precision, recall, and F1 score, achieving a high detection

accuracy rate of 99.50%.

5214-1693458878915-Unit 6 2023 to 2024 academic year assignment (AutoRecovere...

Bigdata of technology

Iron and Steel Technology Roadmap - Towards more sustainable steelmaking.pdf

Iron and Steel Technology towards Sustainable Steelmaking

Literature Review Basics and Understanding Reference Management.pptx

Three-day training on academic research focuses on analytical tools at United Technical College, supported by the University Grant Commission, Nepal. 24-26 May 2024

DfMAy 2024 - key insights and contributions

We have compiled the most important slides from each speaker's presentation. This year’s compilation, available for free, captures the key insights and contributions shared during the DfMAy 2024 conference.

6th International Conference on Machine Learning & Applications (CMLA 2024)

6th International Conference on Machine Learning & Applications (CMLA 2024) will provide an excellent international forum for sharing knowledge and results in theory, methodology and applications of on Machine Learning & Applications.

RAT: Retrieval Augmented Thoughts Elicit Context-Aware Reasoning in Long-Hori...

RAT: Retrieval Augmented Thoughts Elicit Context-Aware Reasoning in Long-Horizon Generation

Recently uploaded (20)

Manufacturing Process of molasses based distillery ppt.pptx

Manufacturing Process of molasses based distillery ppt.pptx

bank management system in java and mysql report1.pdf

bank management system in java and mysql report1.pdf

[JPP-1] - (JEE 3.0) - Kinematics 1D - 14th May..pdf![[JPP-1] - (JEE 3.0) - Kinematics 1D - 14th May..pdf](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![[JPP-1] - (JEE 3.0) - Kinematics 1D - 14th May..pdf](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

[JPP-1] - (JEE 3.0) - Kinematics 1D - 14th May..pdf

Recycled Concrete Aggregate in Construction Part III

Recycled Concrete Aggregate in Construction Part III

2. Operations Strategy in a Global Environment.ppt

2. Operations Strategy in a Global Environment.ppt

DEEP LEARNING FOR SMART GRID INTRUSION DETECTION: A HYBRID CNN-LSTM-BASED MODEL

DEEP LEARNING FOR SMART GRID INTRUSION DETECTION: A HYBRID CNN-LSTM-BASED MODEL

5214-1693458878915-Unit 6 2023 to 2024 academic year assignment (AutoRecovere...

5214-1693458878915-Unit 6 2023 to 2024 academic year assignment (AutoRecovere...

Iron and Steel Technology Roadmap - Towards more sustainable steelmaking.pdf

Iron and Steel Technology Roadmap - Towards more sustainable steelmaking.pdf

Literature Review Basics and Understanding Reference Management.pptx

Literature Review Basics and Understanding Reference Management.pptx

Generative AI leverages algorithms to create various forms of content

Generative AI leverages algorithms to create various forms of content

BPV-GUI-01-Guide-for-ASME-Review-Teams-(General)-10-10-2023.pdf

BPV-GUI-01-Guide-for-ASME-Review-Teams-(General)-10-10-2023.pdf

6th International Conference on Machine Learning & Applications (CMLA 2024)

6th International Conference on Machine Learning & Applications (CMLA 2024)

ML Based Model for NIDS MSc Updated Presentation.v2.pptx

ML Based Model for NIDS MSc Updated Presentation.v2.pptx

RAT: Retrieval Augmented Thoughts Elicit Context-Aware Reasoning in Long-Hori...

RAT: Retrieval Augmented Thoughts Elicit Context-Aware Reasoning in Long-Hori...

Metal casting processes

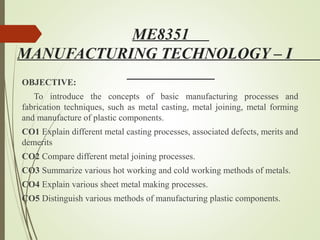

- 1. ME8351 MANUFACTURING TECHNOLOGY – I OBJECTIVE: To introduce the concepts of basic manufacturing processes and fabrication techniques, such as metal casting, metal joining, metal forming and manufacture of plastic components. CO1 Explain different metal casting processes, associated defects, merits and demerits CO2 Compare different metal joining processes. CO3 Summarize various hot working and cold working methods of metals. CO4 Explain various sheet metal making processes. CO5 Distinguish various methods of manufacturing plastic components.

- 2. METAL CASTING PROCESSES Sand Casting : Sand Mould – Type of patterns - Pattern Materials – Pattern allowances –Moulding sand Properties and testing – Cores – Types and applications – Moulding machines– Types and applications; Melting furnaces : Blast and Cupola Furnaces; Principle of special casting processes : Shell - investment – Ceramic mould – Pressure die casting - Centrifugal Casting - CO2 process – Stir casting; Defects in Sand casting

- 3. SAND CASTING Casting is one of the processes used for making components of complicated shapes in large quantity. It is process of producing metal parts by pouring molten metal into the mould cavity of the required shape and allowing the metal to solidify. SAND MOULDS Mould is the cavity of the required shape made in moulding sand or in other material PATTERN It is model of the required casting made in wood, metal, plastics.

- 5. The following factors are very useful for the selection of patterns Size and complexity of the shape Number of components to be produced Method of castings to be used

- 6. TYPES OF PATTERN Solid Split Pattern Loose Piece Pattern Match Plate

- 7. TYPES OF PATTERN Sweep Pattern Skeleton Pattern Segmental Pattern Shell Pattern

- 8. PATTERN MATERIALS The following factors are to be considered for the selection of pattern materials Design of casting Number of castings to be produced Degree of accuracy and surface finish required Shape, complexity and size of the castings Casting or moulding method adopted

- 9. PATTERN MATERIALS 1.0 WOOD • Teak wood, white pine, rose wood are used. • Metal spray coating upto 0.25mm thick, coating materials Zinc and Aluminium to avoid moisture absorption and good surface finish

- 10. PATTERN MATERIALS 2.0 METAL • Mostly used when larger number of castings. • Cast iron, Brass, Aluminium are used.

- 11. PATTERN MATERIALS 3.0 PLASTER • Plaster of paris or gypsum cement is used • Plaster can be easily made into difficult shapes and easily worked. 4.0 PLASTICS • Plastics pattern is cast from a wooden pattern called master pattern. • Light weight but strong and not affected by moisture and more resistant to wear. •Poly acrylates, Poly ethylene, Poly Vinyle chloride etc. • 5.0 WAX It is used in investment castings. Paraffin wax, shellac wax •It has good surface finish and high dimensional accuracy •It is used for making small pattern only

- 12. PATTERN ALLOWANCES: Patterns are not made into exact size of the castings to be produced. Patterns are made slightly larger than the required casting. This extra size given on the pattern is called pattern allowances. Types of pattern allowances: 1. Shrinkage allowance 2. Machining or finish allowance 3. Draft or Taper allowance 4.Distortion or chamber allowance 5. Rapping or shake allowance

- 13. PATTERN ALLOWANCES 1.0 Shrinkage allowance • The extra size provided on the pattern for metal shrinkage is called shrinkage allowance. 2.0 Machining or Finish allowance • The pattern is made larger than the required casting for finishing purpose. •This extra size given to the pattern for machining purpose is called machining or finish allowance.

- 14. PATTERN ALLOWANCES 3.0 Draft or Taper allowance 4.0 Rapping or Shake allowance

- 15. PATTERN ALLOWANCES 5.0 Distortion or Camber allowance

- 16. TYPES OF MOULDING SAND 1.0 Green sand • Moist state is known as green sand. • 5 to 8% of water and 16 to 30 % of clay. • soft, light and porous. 2.0 Dry Sand • Prepared in dry stage. • Used for large casting • Mould does not cause defects which causes due to moisture. 3.0 Facing Sand • Used directly cover the surface of the pattern and comes contact with molten metal. • It contains Silica, Clay, Talc, Graphite etc.. 4.0 Loam Sand • It consists of fine silica sand, fine refractories, clay, graphite, fibre and water • It used for bell, roller, pulley etc. 5.0 Backing sand • It used for backup the facing sand and to fill the whole volume of the mould box. 6.0 Parting sand • It used when a casting is made up of two halves with cope and drag. It is sprinkled over the pattern to avoid sticking of green sand.

- 17. PROPERTIES OF MOULDING SAND 1.0 Porosity or permeability • It is a measure of moulding sand by which the sand allows the steam and gases to pass through it, otherwise casting defects such as blowholes will occur. • It depends on Quality and quantity of clays, Moisture, Degree of compactness. 2.0 Plasticity or flowability • It should flows around and over the pattern, uniformly fills the flask. 3.0 Adhesiveness • It sticks or adheres to moulding boxes. It does not fall out when the flasks are lifted and turned over. 4.0 Strength or cohesiveness • It should have sufficient strength so that the mould does not collapse during lifting, shifting, turning, pouring the molten metal. 5.0 Refractoriness • It should resist high temperature of molten metal and depends on purity of the sand, sizes. 6.0 Collapsibility • It should collapse easily after the casting solidifies.

- 18. TESTING OF MOULDING SAND Moisture content test Clay content test Grain fineness test Permeability test Strength test Deformation and toughness test Hot strength test Refractoriness test Mould hardness test

- 19. TESTING OF MOULDING SAND 1.0 Moisture content test a) Loss of weight after evaporation Moisture content = W1 – W2 % of moisture content = (W1 – W2) x 100 W1 b) Moisture teller method c) Based on chemical reaction CaC2 + 2H2O C2H2 + Ca (OH)2 Depending upon the amount of acetylene gas, moisture content is determined.

- 20. TESTING OF MOULDING SAND 2.0 Clay content test Sand + distilled water + 1% NaOH stirred 5 min and settle down 10 min sand + clean water. Clay content = W1 – W2, W1 – weight of sand before drying, W2 – after drying. % of clay content = (W1 – W2) x 100 W1 3.0 Grain fineness test

- 21. TESTING OF MOULDING SAND 4.0 Permeability test Tendency of sand which allows the escape of gases or air through it. Permeability number = VH / APT V = Volume of air (2000cc) H = Height of the specimen = 50.8mm A = Area of specimen = πd2 /4 =20.268cm2 T = Time taken by 2000cc P = Pressure measured in manometer.

- 23. TESTING OF MOULDING SAND 5.0 Strength test Measure of holding power or bonding power. a)Compressive strength b)Shear strength c)Tensile strength d)Bending strength

- 25. TESTING OF MOULDING SAND 6.0 Deformation and Toughness test Deformation – Plasticity of sand can be tested by applying compressive force. Toughness –The deformation of green compressive strength provides the quality of sand mix. 7.0 Hot strength test 8.0 Refractoriness test

- 26. TESTING OF MOULDING SAND 9.0 Hardness test Indicates the ramming density of the actual sand mould.

- 27. CORES A core is a body made of sand which is used to make a cavity or a hole in the casting. Essential qualities of a core Permeability Refractoriness Strength Collapsibility Stability

- 28. Core making materials A core is made of core sand, binder and additives Core sand consists of refractories such as silica sand, zircon, olivine etc Binders contains of vegetable oil or mineral oil, core flour, resins water, fire clay, urea. Additives are wood flour, coal powder, graphite, cow dung.

- 29. Core Boxes Core boxes are used to produce cores. It is made of wood or metal

- 31. Core Ovens Core ovens are used for heating the cored to obtain required hardness. Batch type oven Continuous type oven Dielectric baking oven

- 33. Types of core According to the state of core Green sand core Dry sand core According to the position of the core in the mould Horizontal core Vertical core Balanced core Hanging core Drop core

- 37. Various methods of testing core sand The various core sand tests are Green strength test Permeability test Baked strength test Hot strength test Retained strength test Core hardness test Moisture content test

- 38. MOULDING MACHINES Moulding machines is used for mass production. Since the hand moulding is a slow process, only making few casting. For more castings, Moulding is done by using moulding machines. TYPES OF MOULDING MACHINES a) Jolting Machine Raised about 80mm and suddenly dropped.

- 39. TYPES OF MOULDING MACHINES b) Squeezing Machine The mould sand in the flask is squeezed between the machine table and squeezer head.

- 40. c) Sand Slinger Impeller rotates, it will throw a stream of sand at great velocity into the flask.

- 41. MELTING FURNACES 1.0 CUPOLA FURNACE

- 44. 2.0 CRUCIBLE FURNACE a. Pit Furnace APPLICATIONS Used for melting cast iron and non ferrous metals and alloys in small quantity.

- 45. b. Coke Fired Stationary Furnace

- 46. c. Oil Fired Tilting Furnace Advantages

- 47. 3.0 ELECTRIC FURNACE a. Direct Arc Furnace

- 49. b. Indirect Arc Furnace

- 51. SPECIAL CASTING PROCESSES 1.0 SHELL MOULD CASTING

- 53. 4.0 PRESSURE DIE CASTING a. HOT CHAMBER DIE CASTING

- 54. b. COLD CHAMBER DIE CASTING

- 56. 6.0 CERAMIC MOULD CASTING

- 57. CORE MAKING

- 58. CO2 PROCESS

- 59. 7.0 CO2 PROCESS • Pure dry silica sand mixed with sodium silicate liquid use as a binder for making core. • NaSiO3 + CO2----------- NaCO3 + SiO2 • Moisture should not exceed 3%. • CO2 gas is passed through the core for 30 sec at a pressure of 140 KN/m2 . • CO2 react with sodium silicate and forms sodium carbonate and silica gell. • Silica gell binds the sand grains together to provide strength and hardness to the core.

- 60. Stir Casting