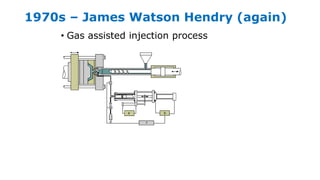

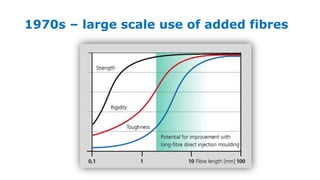

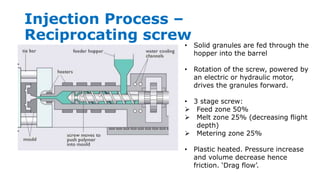

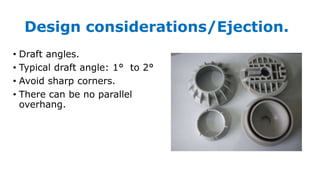

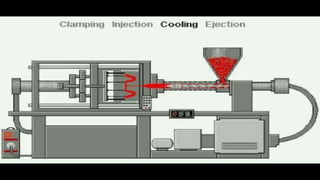

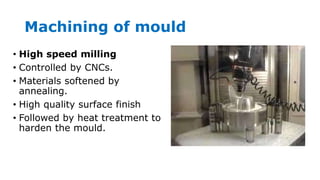

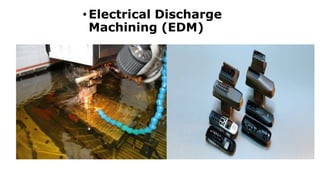

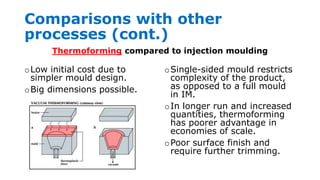

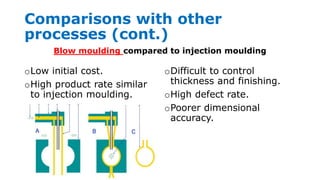

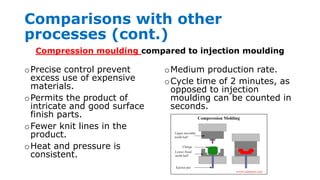

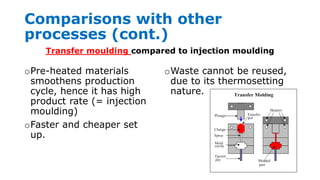

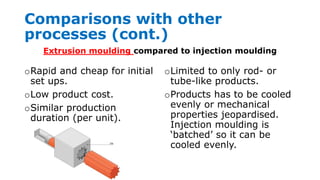

The document provides a comprehensive overview of injection moulding, covering its history, business context, and various processes involved, including mould design and comparisons with alternative methods. Key historical innovations and cost dynamics are highlighted, alongside the technical details of the injection process and mould characteristics. It also discusses the advantages and disadvantages of injection moulding relative to other manufacturing techniques such as thermoforming, blow moulding, and compression moulding.