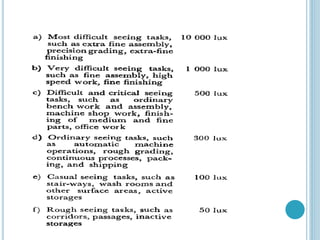

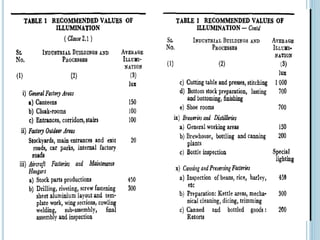

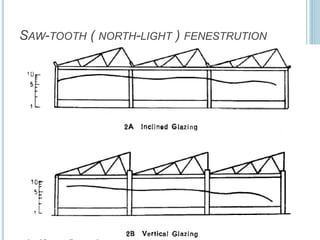

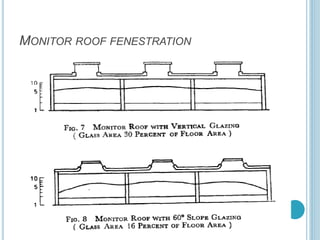

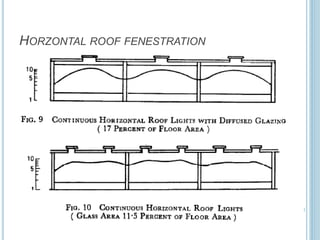

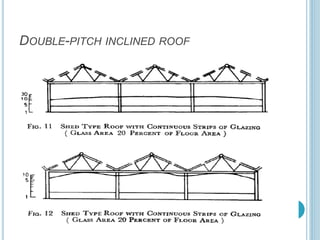

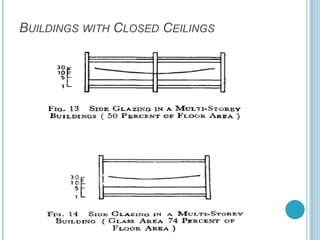

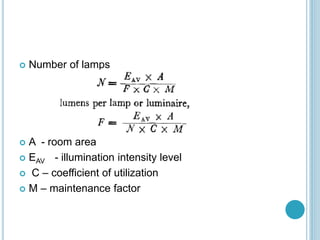

Good lighting in factories enables workers to perform visual tasks easily without fatigue or eye strain. It helps reduce waste and improve productivity. Recommended illumination levels depend on the task and are set by organizations like the Illumination Engineering Society. Lighting should be well distributed without glare or excessive brightness contrasts. Daylighting is preferable and can be achieved through designs like sawtooth roofs, monitors, or horizontal fenestration, but direct sun should be screened. Artificial lighting may be needed as permanent supplementary lighting according to formulas considering the area, required intensity level, and efficiency factors.