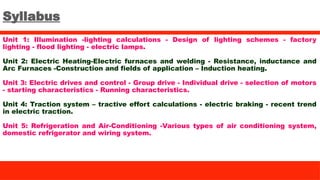

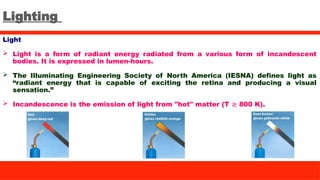

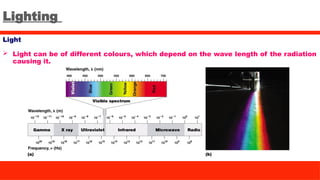

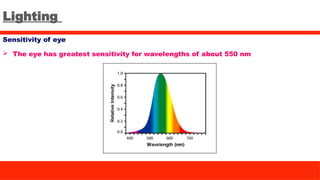

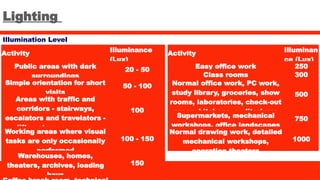

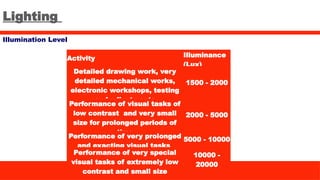

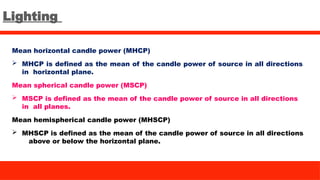

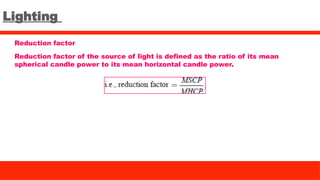

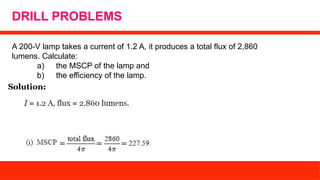

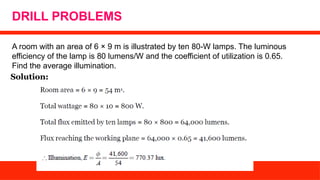

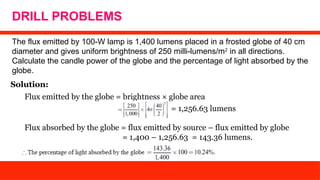

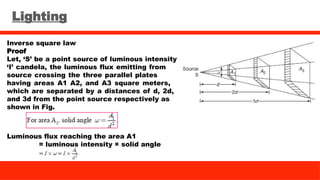

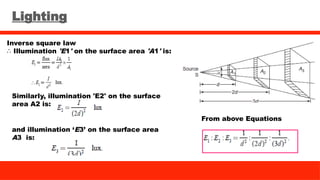

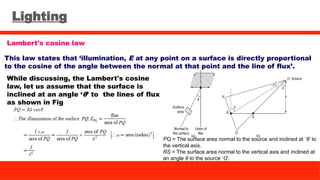

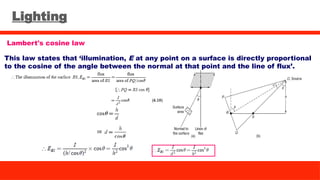

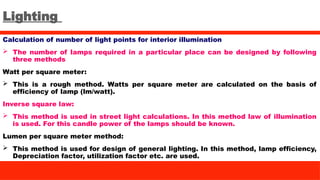

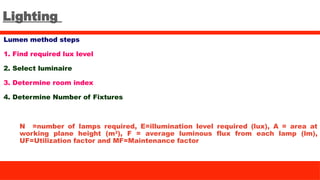

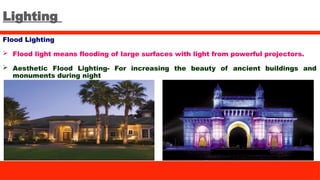

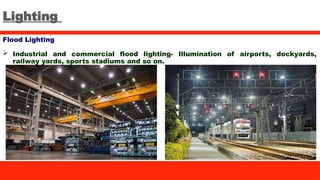

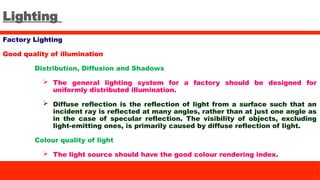

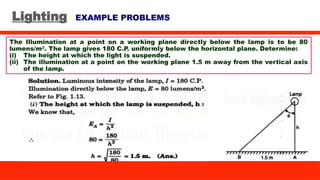

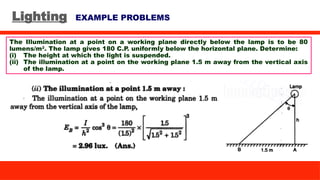

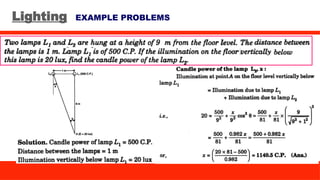

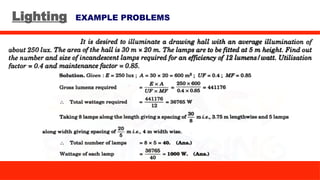

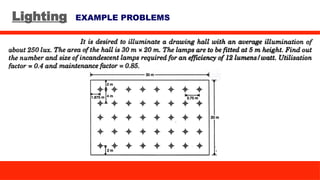

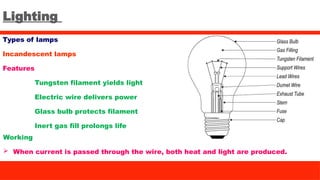

The document outlines the syllabus for a course on the utilization of electrical energy, covering topics such as illumination, electric heating, electric drives, traction systems, and refrigeration. It includes detailed definitions and measurements relating to lighting, the effects of glare and shadows, and methods for calculating illumination requirements. Reference books are also provided to aid in understanding the concepts discussed.