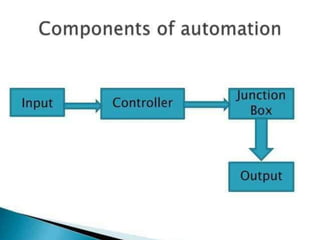

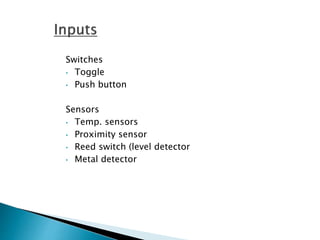

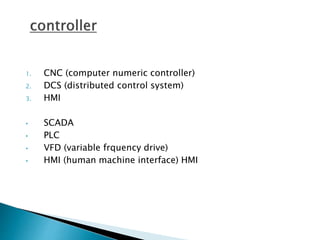

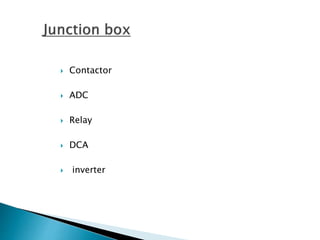

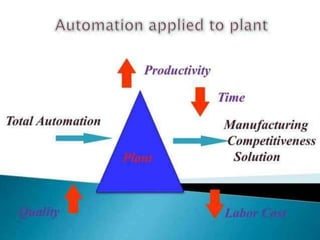

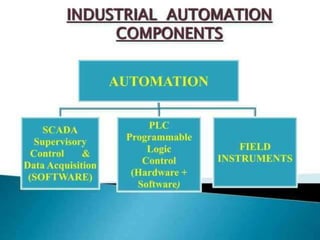

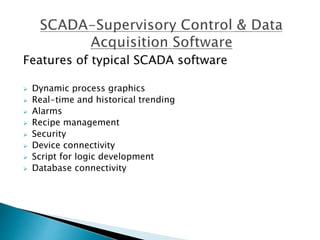

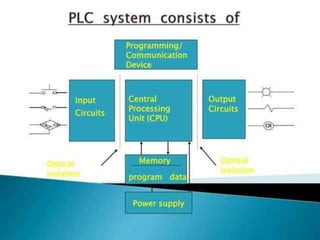

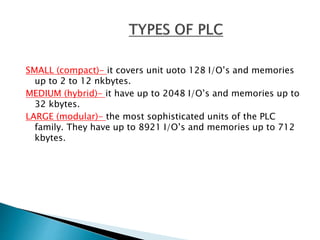

The document discusses industrial automation using SCADA (Supervisory Control and Data Acquisition) systems and PLC (Programmable Logic Controller). It defines SCADA as a type of industrial control system that monitors and controls physical processes. PLCs are solid-state computers that perform logic functions to interface between field inputs/outputs in a factory environment. The document outlines the components, applications, advantages and disadvantages of SCADA systems and PLCs in industrial automation.