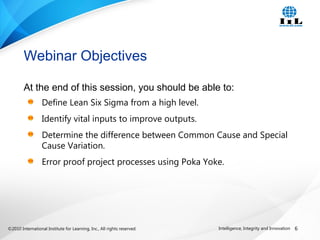

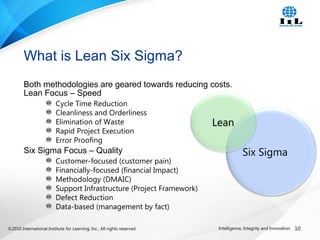

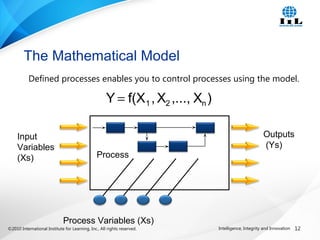

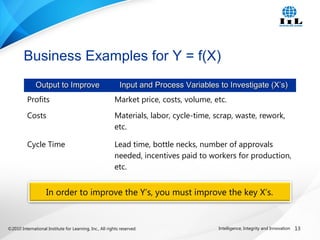

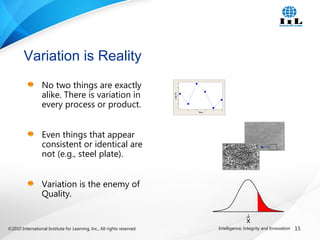

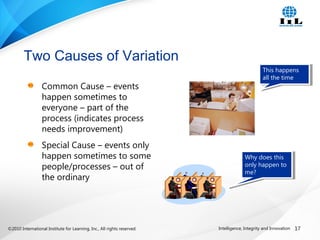

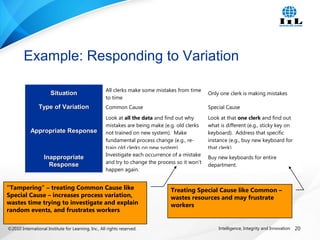

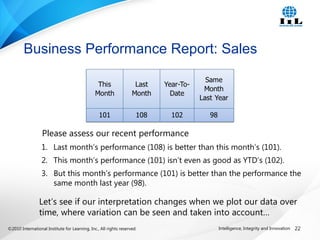

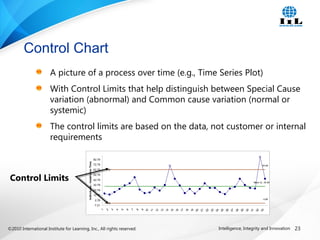

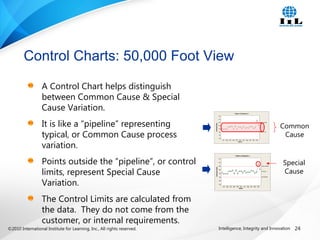

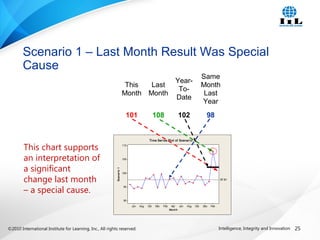

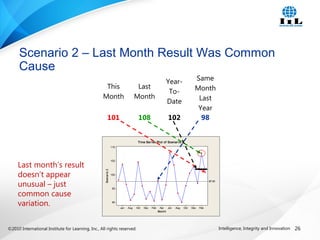

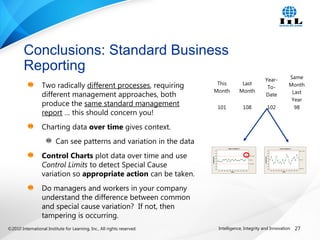

The webinar focuses on introducing project managers to essential Lean Six Sigma concepts aimed at improving project and product quality. Participants will learn how to define Lean Six Sigma, identify critical inputs for output improvement, and differentiate between common and special cause variations. Key techniques such as poka yoke for error-proofing processes will also be discussed to enhance quality management.