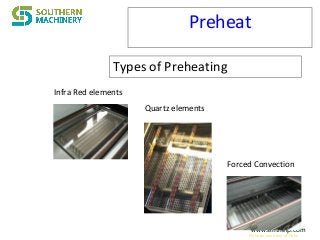

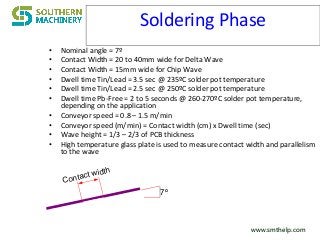

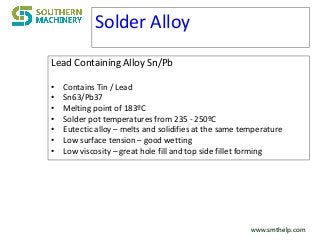

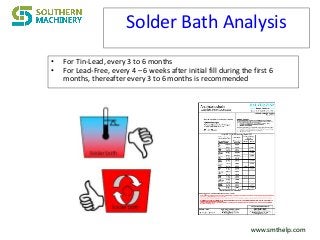

This document provides information on improving wave soldering processes. It discusses the basic 6 steps of wave/selective soldering including component preparation, flux application, preheating, soldering, and cooling. It also covers topics like preforming lead components, hole sizes, selective pallets, wave nozzle configurations, solder alloys, fluxing methods, preheating, and common problems troubleshooting wave soldering. The document is from Shenzhen Southern Machinery and provides their contact information.