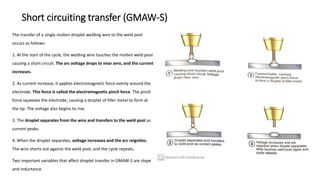

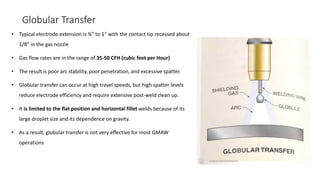

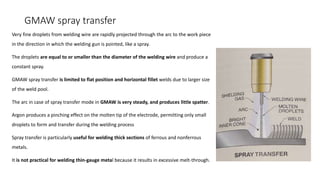

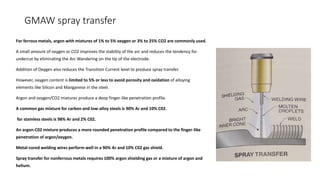

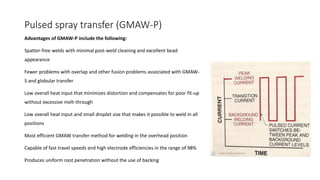

Gas metal arc welding (GMAW), commonly known as MIG/MAG welding, utilizes a continuously fed wire electrode and shielding gas to create welds. Various metal transfer modes include short circuiting transfer (GMAW-S), globular transfer, spray transfer, and pulsed spray transfer (GMAW-P), each with distinct applications and characteristics. The document details the equipment, shielding gases, and the advantages and challenges associated with each transfer mode.