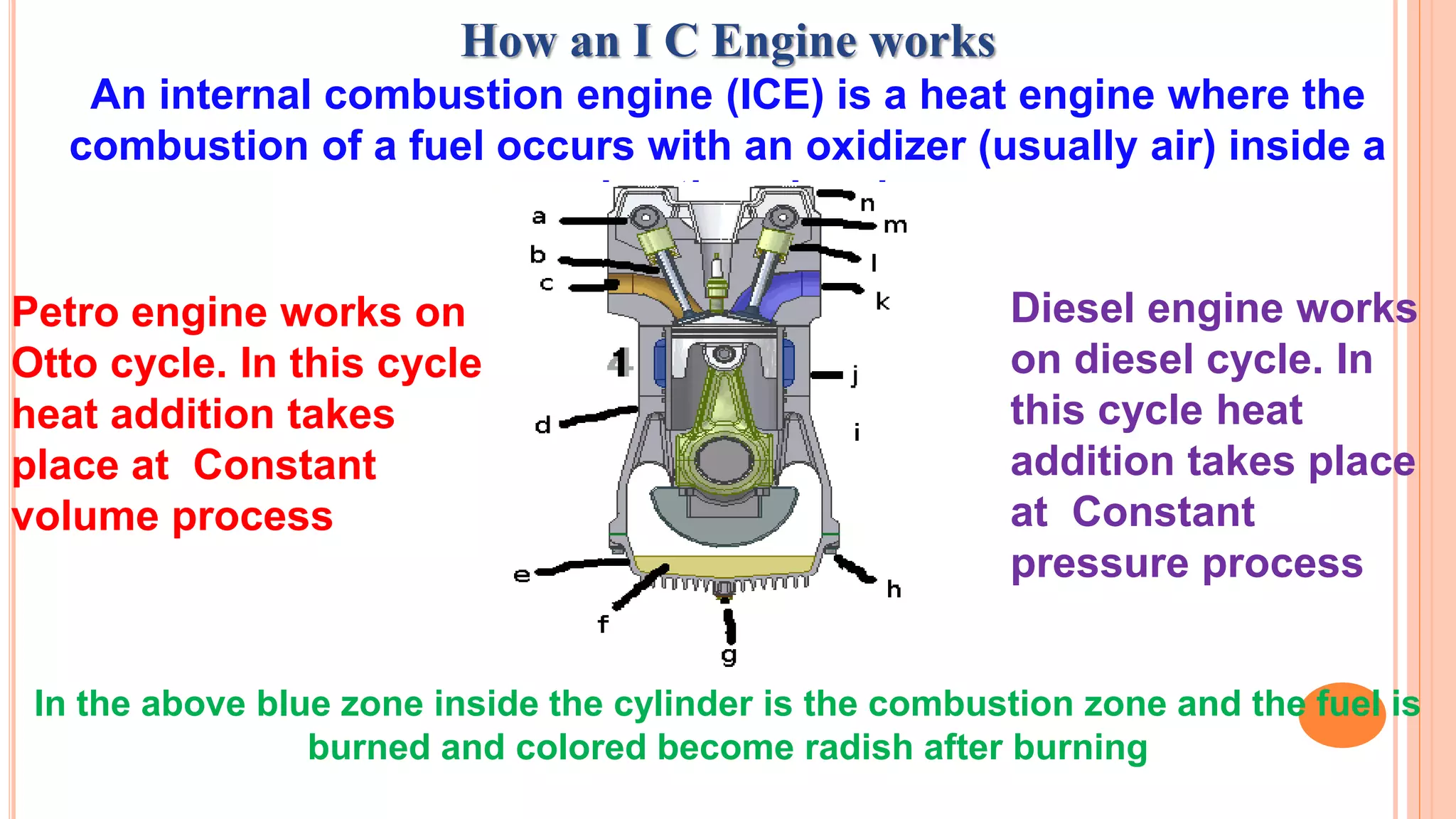

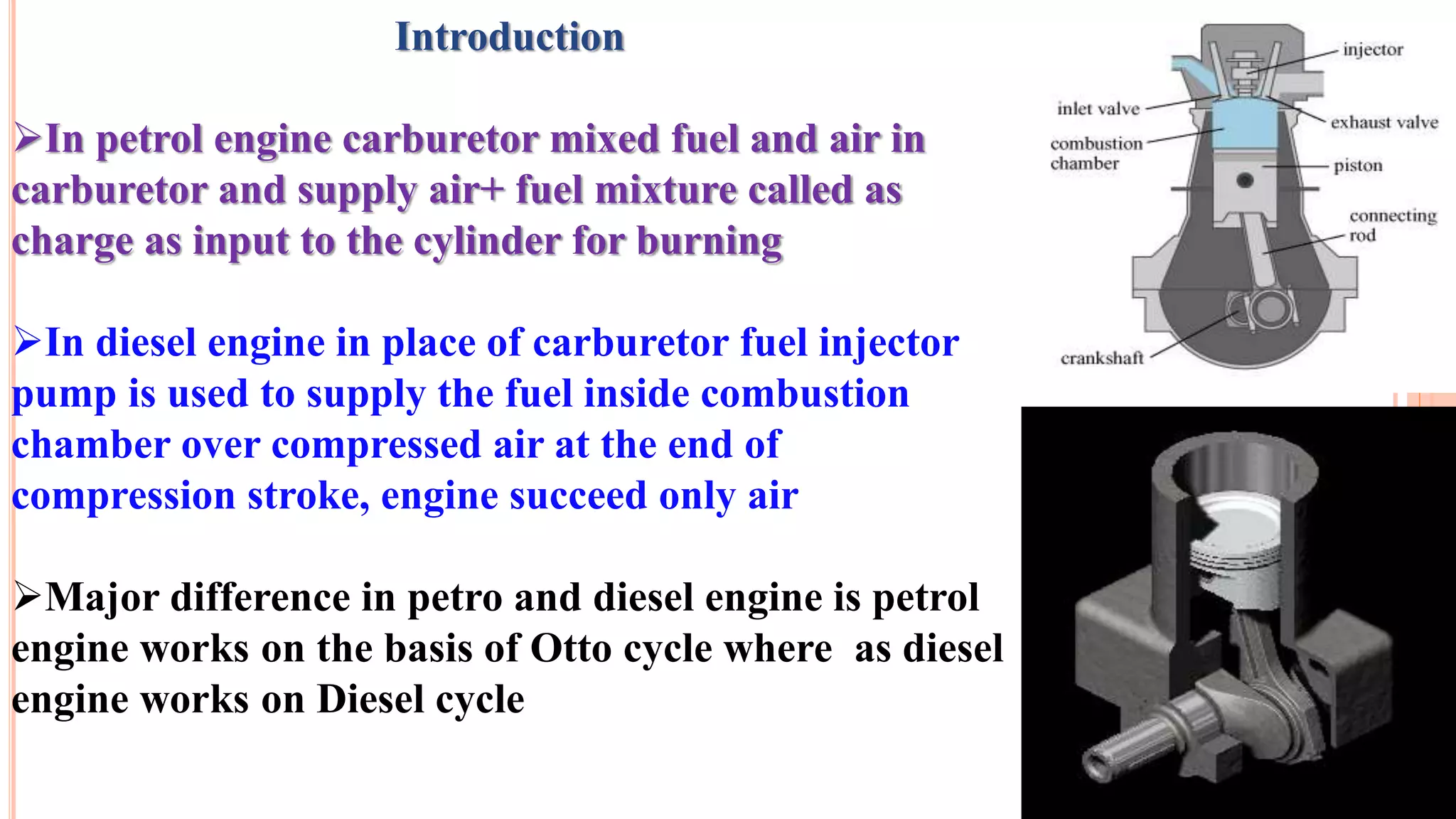

This document provides information on fuels, internal combustion engines, and their basic workings. It discusses the main types of fuels like petroleum, coal, natural gas, and orimulsion. It then explains the differences between external combustion engines like steam engines, where combustion occurs outside the engine, versus internal combustion engines where combustion occurs inside. It provides details on the operation of two-stroke and four-stroke internal combustion engines, including their valve timing and intake/exhaust processes. It also describes the major components and parts of internal combustion engines, lubrication and cooling systems, and the Otto and Diesel cycles that petrol and diesel engines respectively operate on.