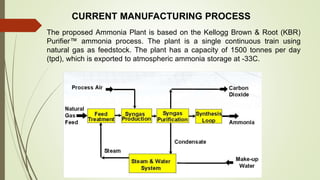

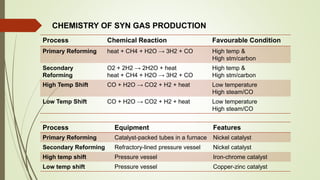

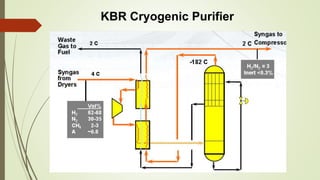

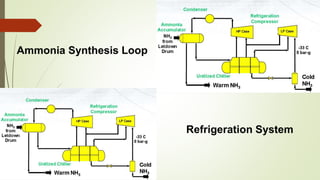

The KBR process for ammonia synthesis uses natural gas as a feedstock that is reformed through primary and secondary reforming to produce syngas. The syngas is then purified through shift conversion, CO2 removal, methanation, drying and cryogenic purification. The purified syngas is then used to synthesize ammonia through a reaction with nitrogen in the presence of a catalyst at high pressure and moderate temperatures. The KBR process offers advantages such as a clean syngas that reduces load on equipment and achieves higher conversion efficiency through low inert content.