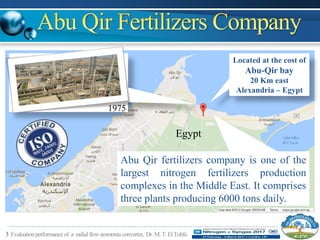

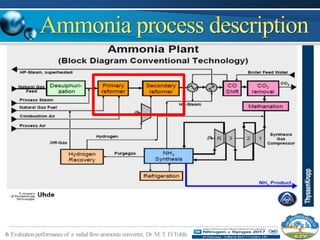

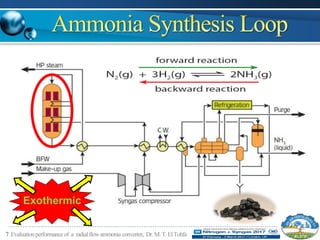

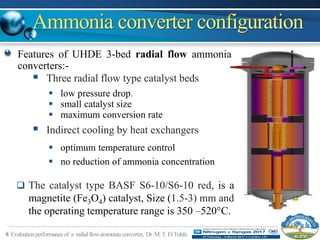

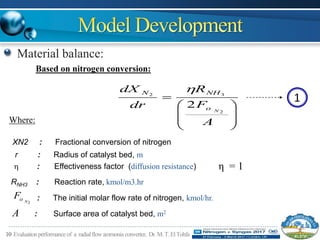

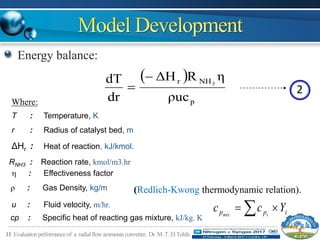

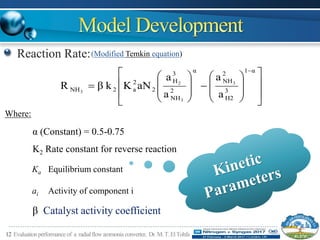

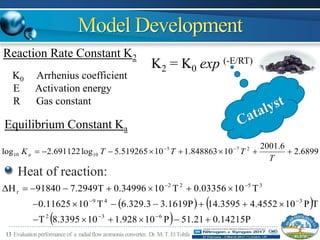

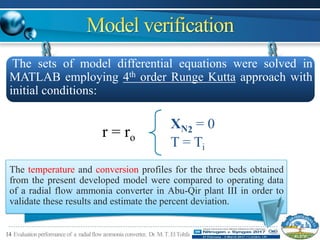

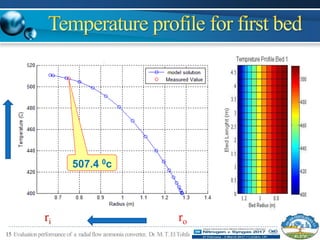

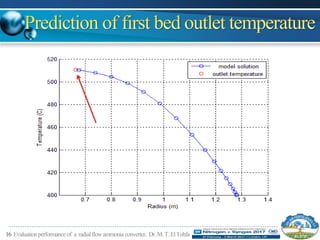

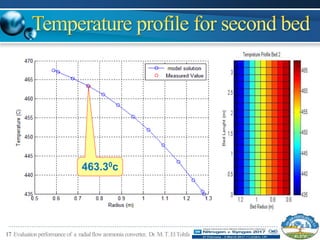

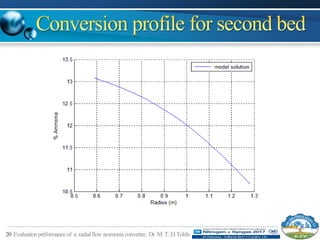

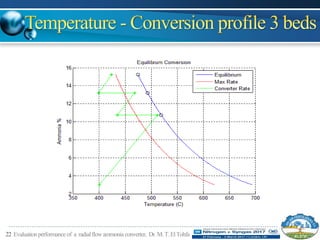

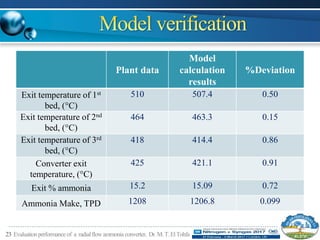

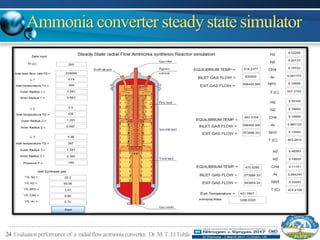

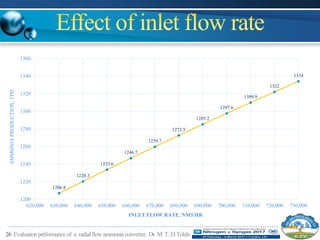

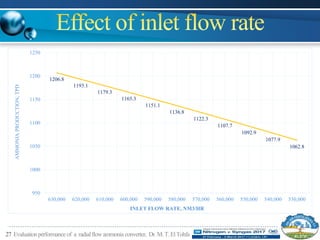

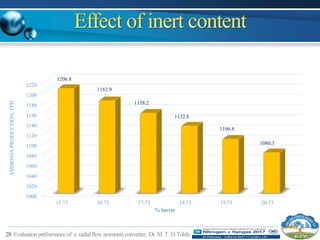

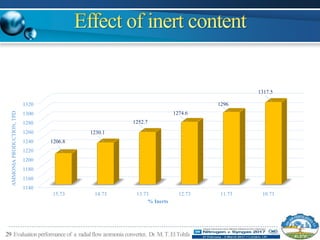

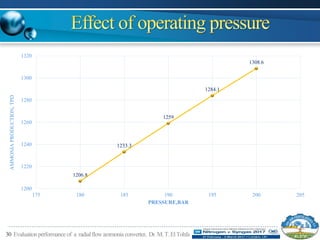

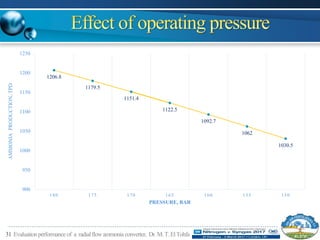

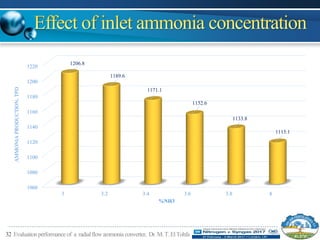

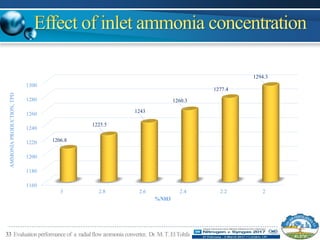

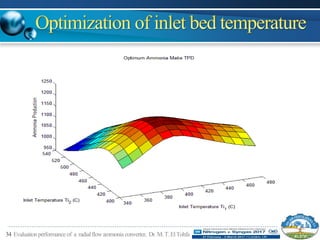

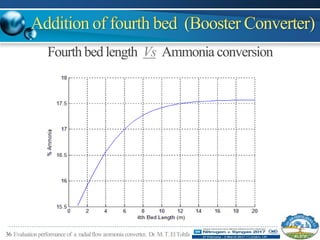

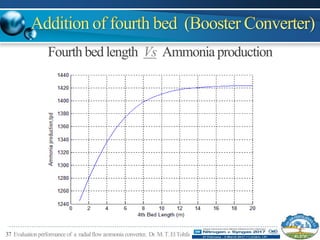

This document describes the development and validation of a mathematical model for a radial flow ammonia converter. The model equations account for material and energy balances across the three catalyst beds. Comparison to plant data from Abu Qir Fertilizers Company showed good agreement between the model and actual performance. The model is useful for optimizing operating conditions, evaluating catalyst performance over time, and determining the effects of adding a fourth catalytic bed.