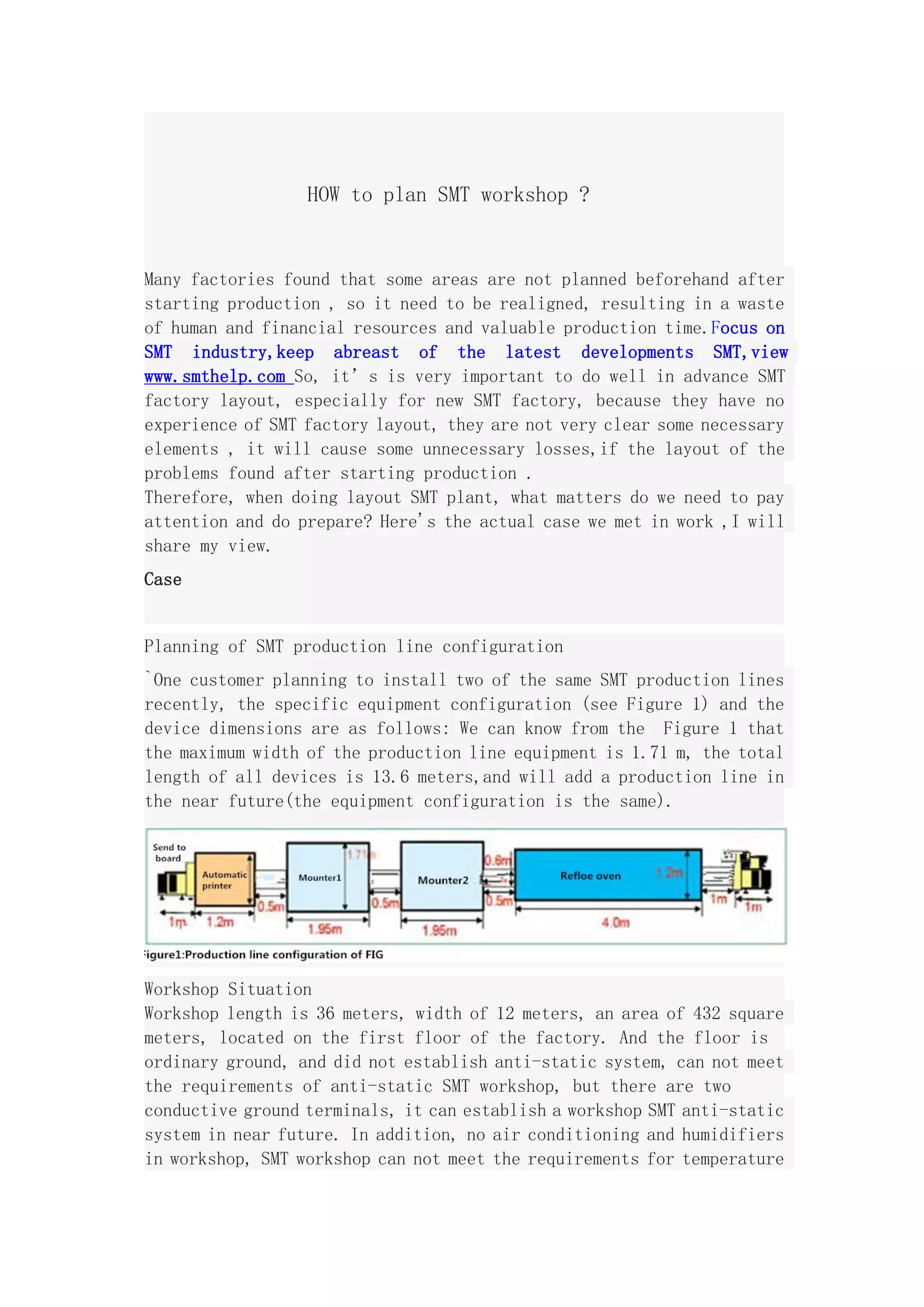

The document discusses planning an SMT workshop layout. It describes a case of planning for two production lines and considers factors like equipment dimensions, workshop size, and future expansion. The layout positions the lines along the workshop length, leaving space between for access. It then discusses placement of auxiliary equipment and areas for materials, trash, quality monitoring, and more. The overall goal is to arrange the workshop neatly and meet requirements for temperature control, anti-static measures, material storage, and ventilation across multiple production lines.