The document defines different types of production layout formats including process layout, product layout, group technology (cellular) layout, and fixed-position layout. It then provides examples of using systematic layout planning techniques and computerized layout programs like CRAFT to develop optimized process layouts that minimize material handling costs based on interdepartmental flow data. The examples show how simple exchanges aimed at cost reduction can actually increase costs due to unintended impacts on other department relationships. Overall layout optimization requires consideration of both quantitative factors like costs as well as qualitative factors such as safety and workflow.

![FACILITY LAYOUT technical note 197

S P L I T T I N G TA S K S

Often the longest required task time forms the shortest workstation cycle time for the pro-

duction line. This task time is the lower time bound unless it is possible to split the task into

two or more workstations.

Consider the following illustration: Suppose that an assembly line contains the follow-

ing task times in seconds: 40, 30, 15, 25, 20, 18, 15. The line runs for 71

2 hours per day and

demand for output is 750 per day.

The workstation cycle time required to produce 750 per day is 36 seconds ([71

2

hours ×

60 minutes × 60 seconds]/750). Our problem is that we have one task that takes 40 sec-

onds. How do we deal with this task?

There are several ways that we may be able to accommodate the 40-second task in a

36-second cycle. Possibilities are

1 Split the task. Can we split the task so that complete units are processed in two

workstations?

2 Share the task. Can the task somehow be shared so an adjacent workstation does

part of the work? This differs from the split task in the first option because the adja-

cent station acts to assist, not to do some units containing the entire task.

3 Use parallel workstations. It may be necessary to assign the task to two work-

stations that would operate in parallel.

4 Use a more skilled worker. Because this task exceeds the workstation cycle time

by just 11 percent, a faster worker may be able to meet the 36-second time.

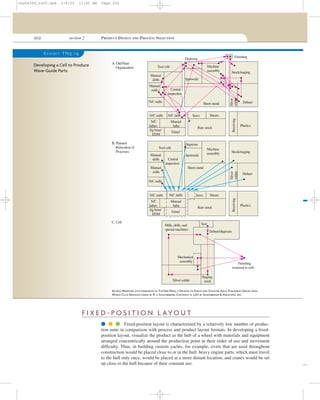

E X H I B I T TN5.12REMAINING TASK WITH

UNASSIGNED FEASIBLE TASK WITH LONGEST

TASK TIME TIME REMAINING MOST OPERATION

TASK (IN SECONDS) (IN SECONDS) TASKS FOLLOWERS TIME

Station 1 A 45 5.4 idle None

Station 2 D 50 0.4 idle None

B 11 39.4 C, E C, E E

E 15 24.4 C, H, I C

Station 3

C 9 15.4 F, G, H, I F, G, H, I F, G, H, I

F* 12 3.4 idle None

G 12 38.4 H, I H, I H, I

H* 12 26.4 I

Station 4

I 12 14.4 J

J 8 6.4 idle None

Station 5 K 9 41.4 idle None

*Denotes task arbitrarily selected where there is a tie between longest operation times.

A. Balance Made According

to Largest-Number-of-

Following-Tasks Rule

A

45 sec.

11 sec. 9 sec.

12 sec.

8 sec. 9 sec.12 sec.15 sec.50 sec.

12 sec.

12 sec.B C

F

G

J KHED

I

WS 1

WS 2

WS 3

WS 4

WS 5

B. Precedence Graph for Model

J Wagon

C. Efficiency CalculationEfficiency = = = .77, or 77%

195

(5)(50.4)

T

NaC

{

{

cha06369_tn05.qxd 3/4/03 11:05 AM Page 197](https://image.slidesharecdn.com/6184-7tn05-130715045843-phpapp01/85/6184-7-tn05-12-320.jpg)