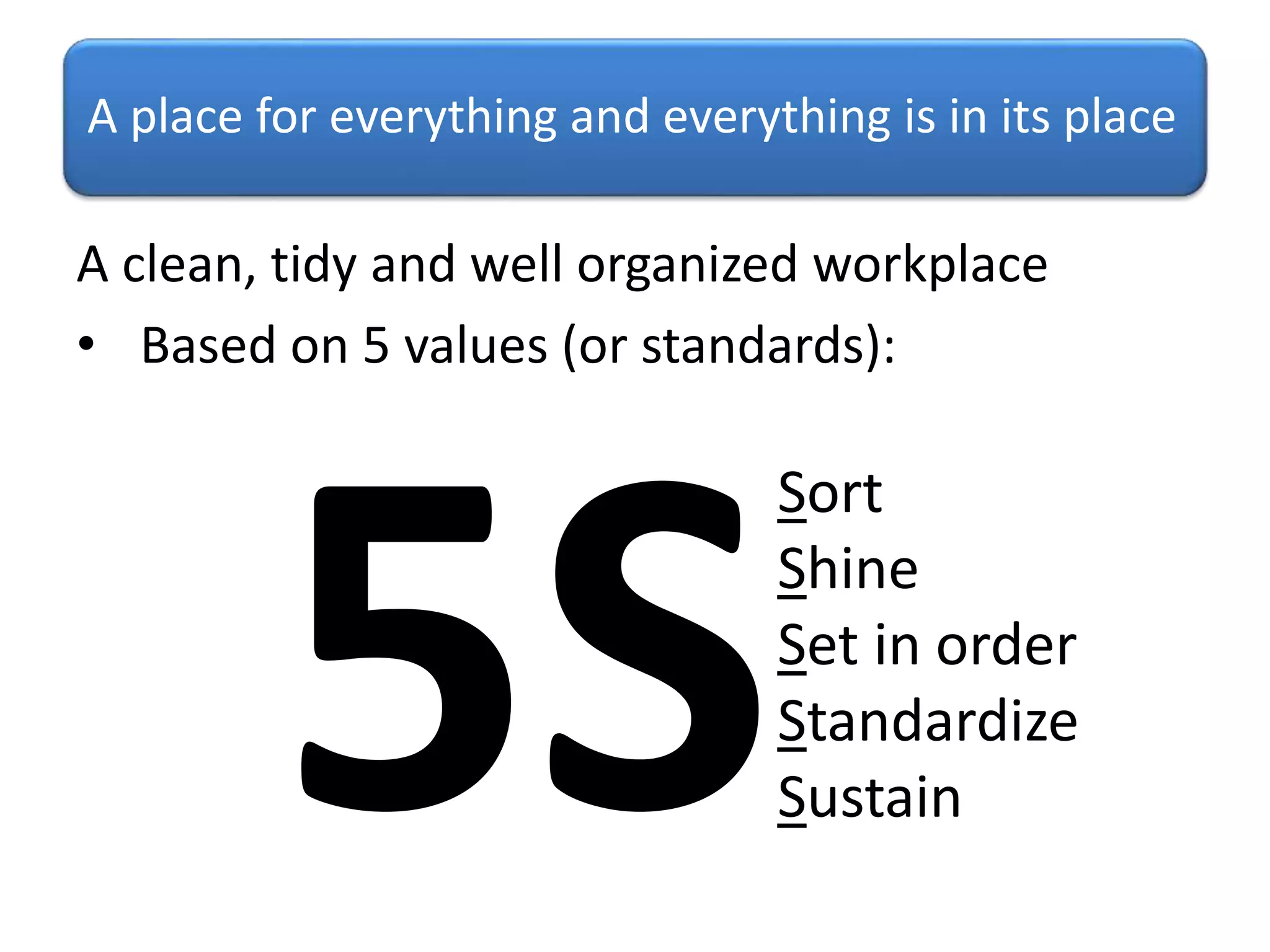

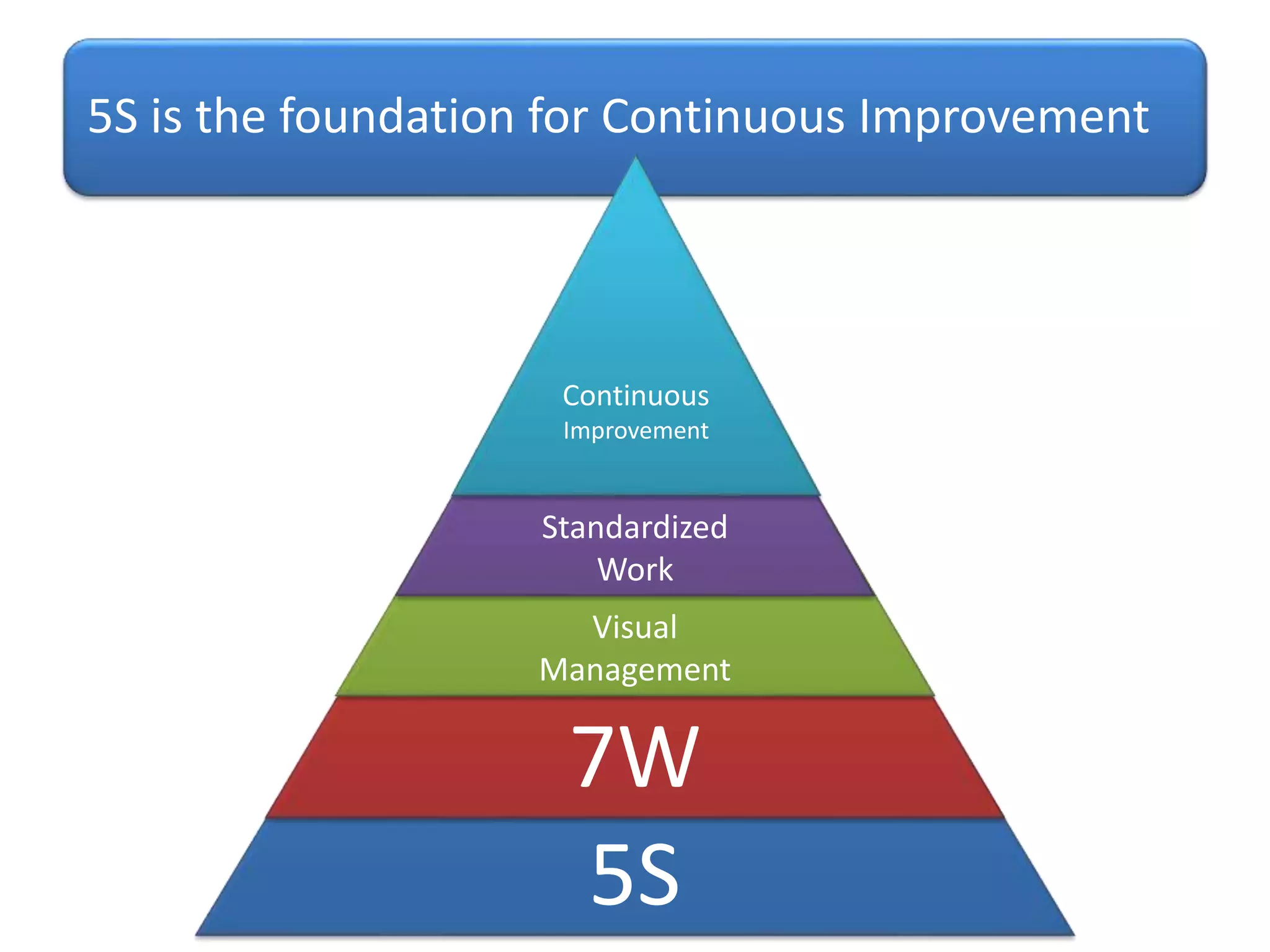

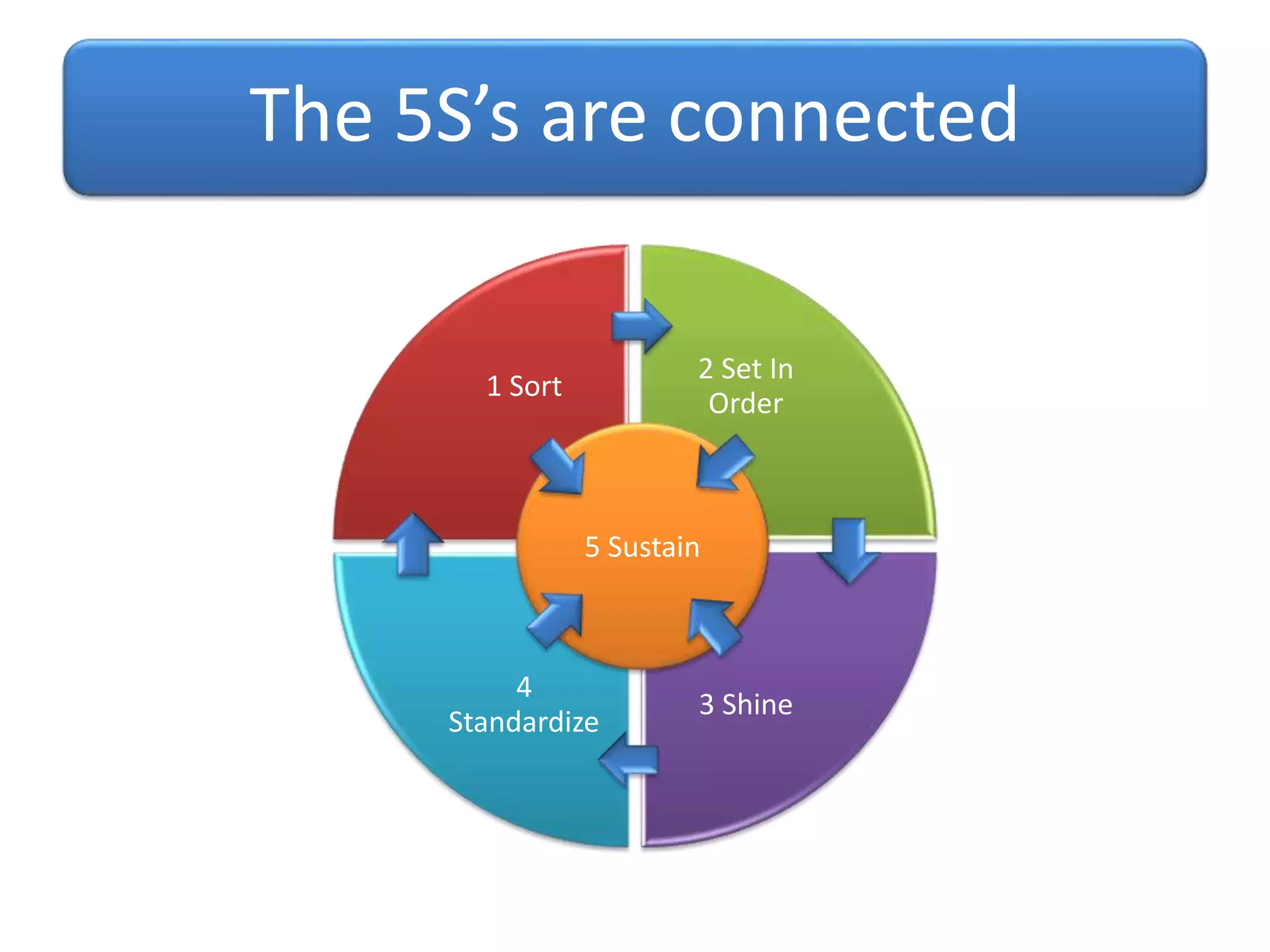

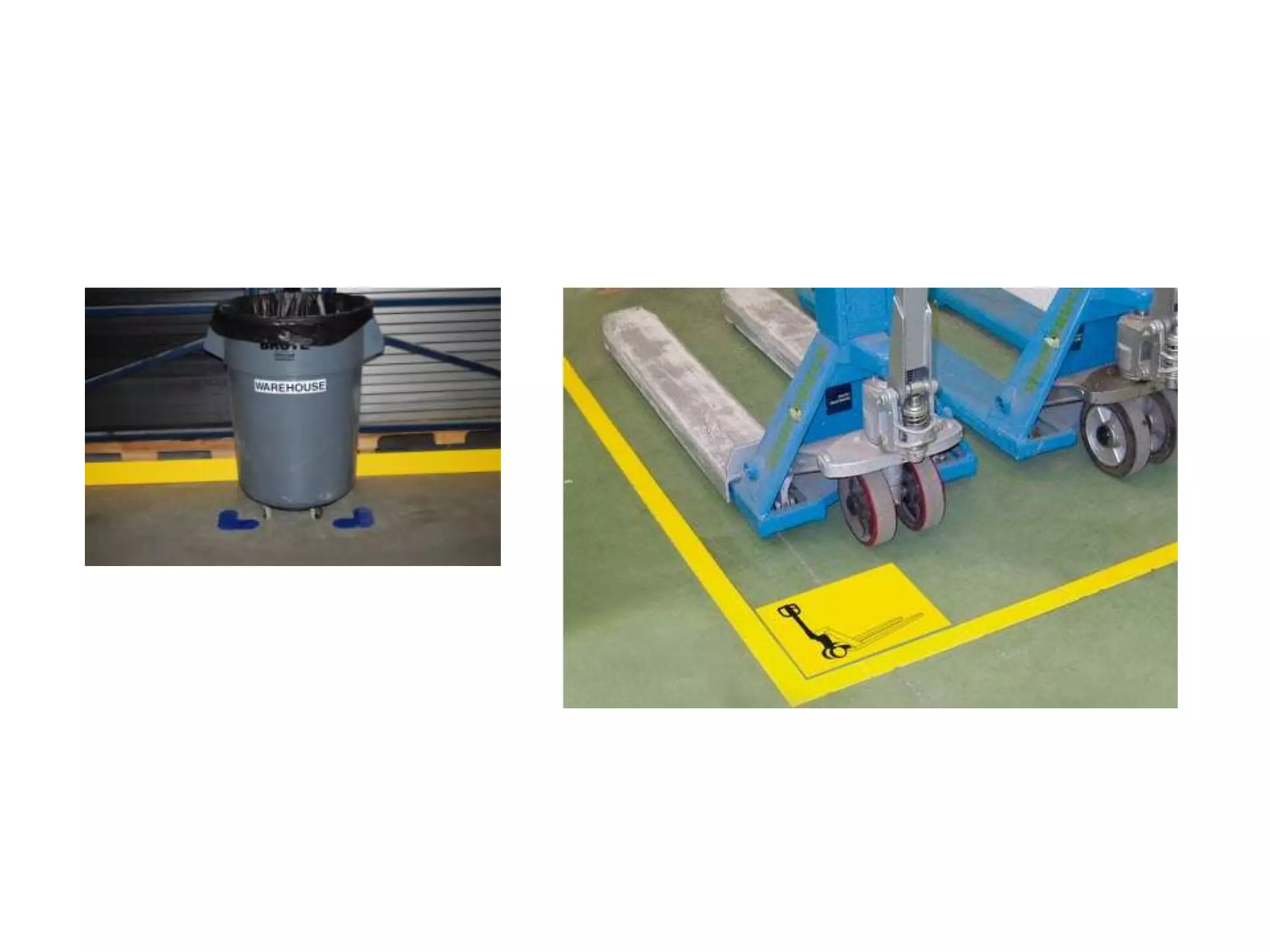

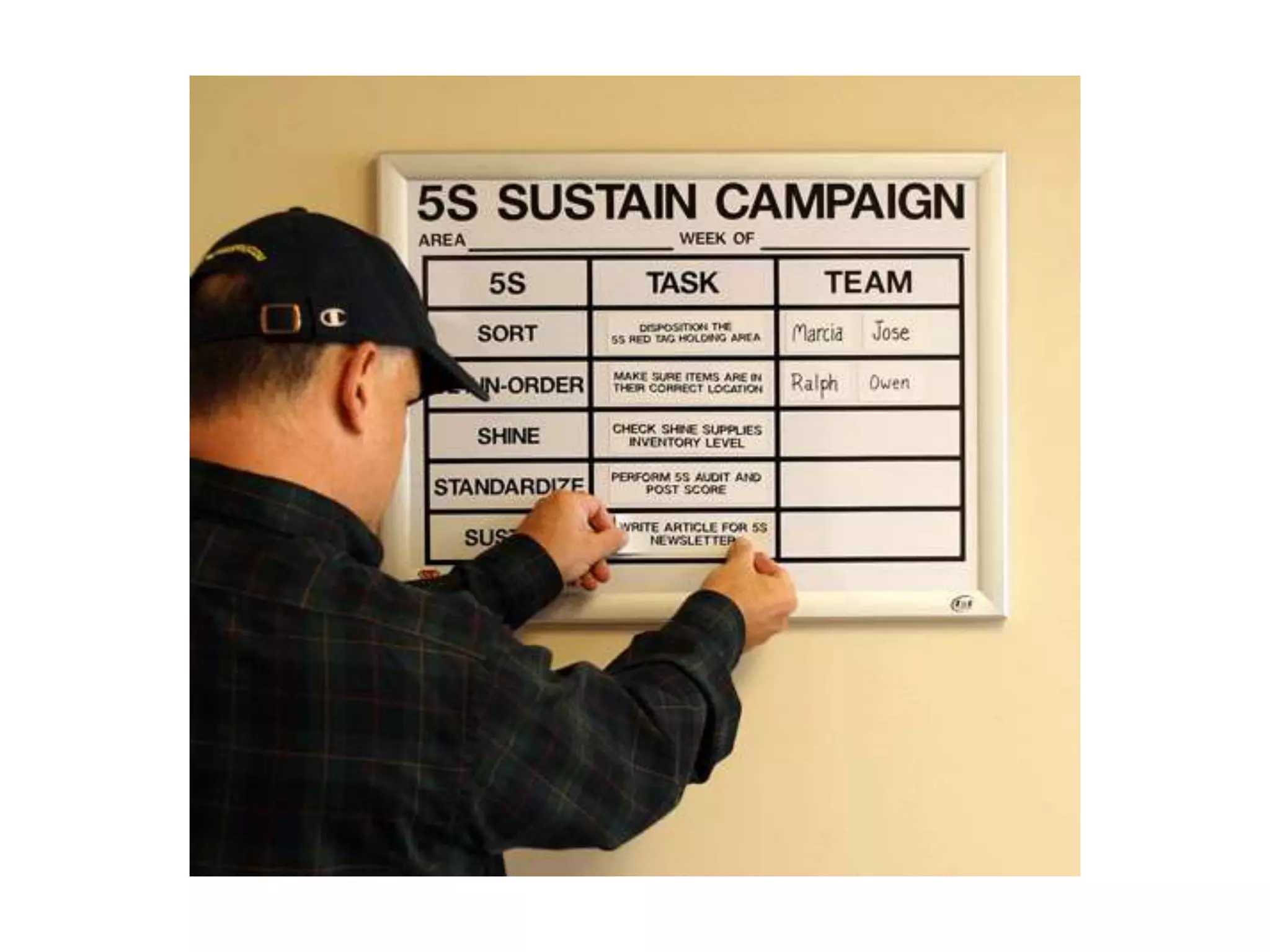

5S is a tool to create a clean, tidy, and well-organized workplace. It involves 5 phases: Sort, Set In Order, Shine, Standardize, and Sustain. The goal is to establish visual standards and work procedures to reduce waste and mistakes and continuously improve the workplace.