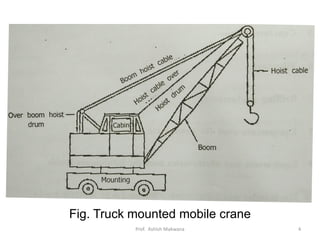

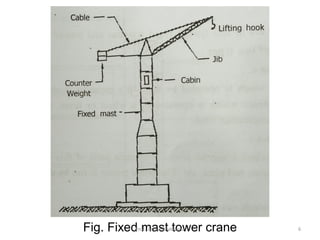

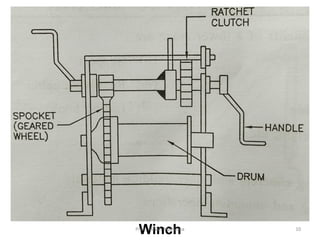

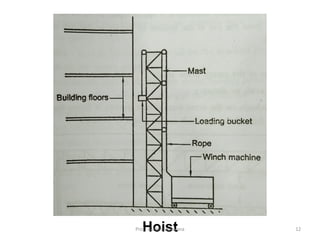

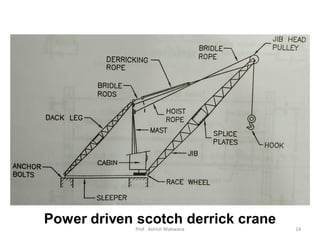

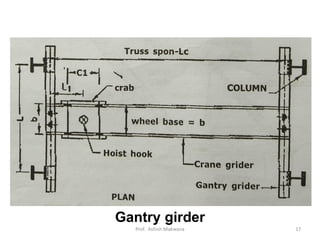

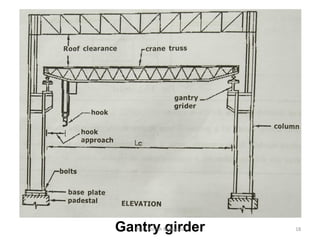

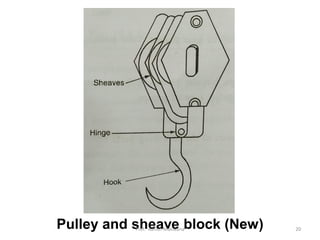

The document, prepared by Prof. Ashish Makwana, outlines various types of cranes and lifting mechanisms used in construction, including mobile cranes, tower cranes, winches, hoists, and gantry cranes. Each type is described with its functions, components, and applications, highlighting their importance in handling heavy loads and facilitating construction work. The document covers detailed specifications and operational capabilities of each lifting device.