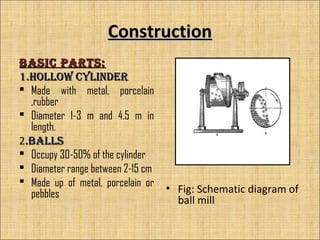

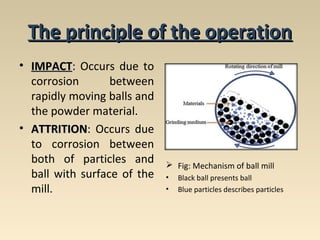

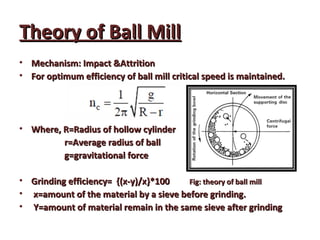

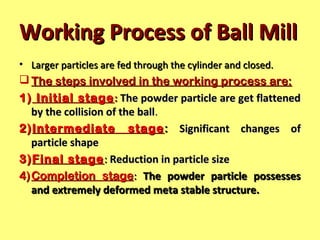

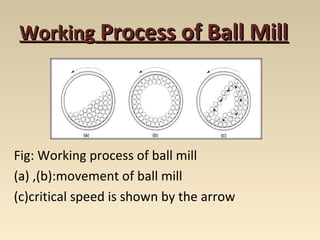

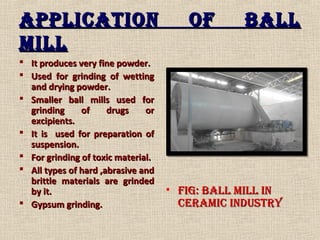

The document summarizes the ball mill, which is a grinder used to grind and blend materials. It discusses the basic parts of a ball mill including the hollow cylinder and balls. It then explains the principle of operation through impact and attrition. The document also covers the theory behind maintaining critical speed for optimum efficiency. Additionally, it describes the working process, how to improve efficiency, merits and demerits, applications, and concludes that ball mills are widely used in pharmaceutical industries for grinding processes.