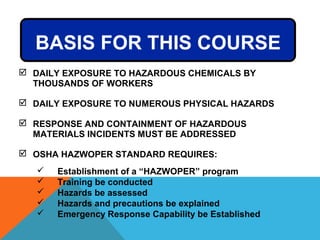

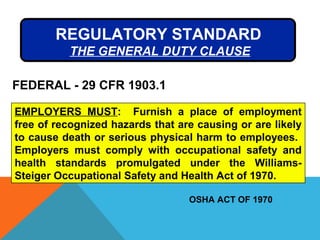

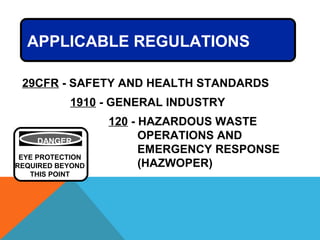

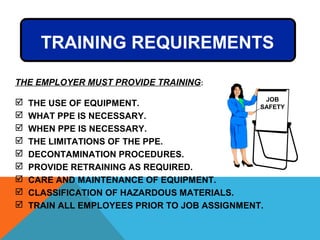

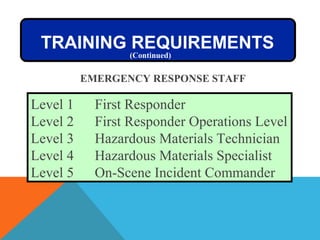

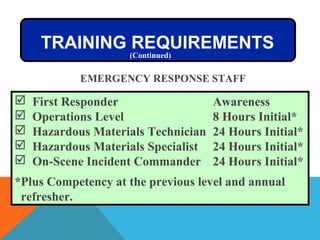

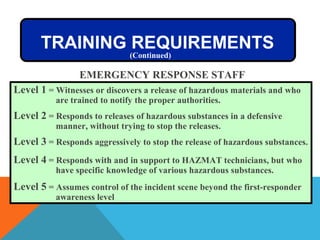

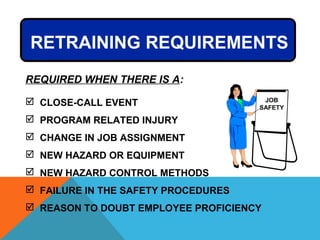

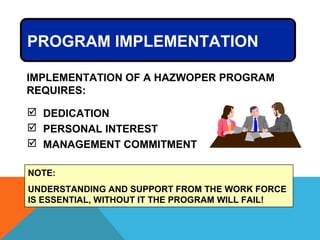

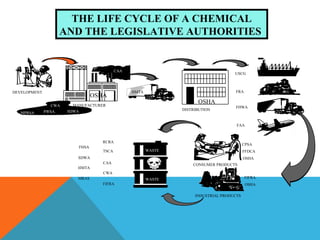

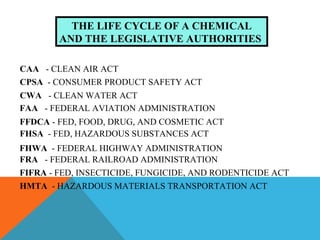

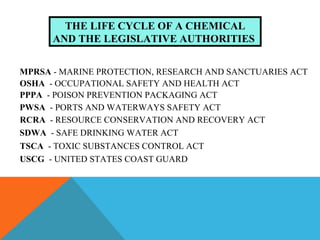

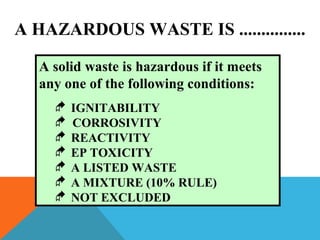

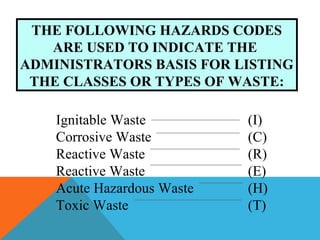

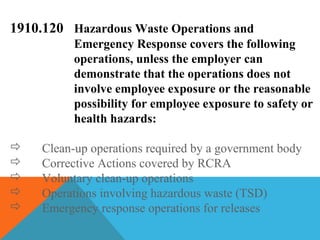

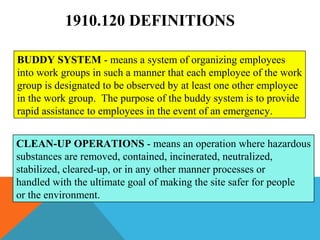

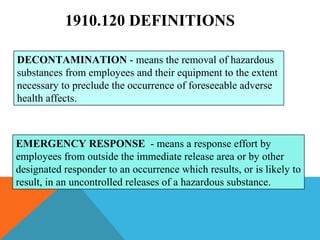

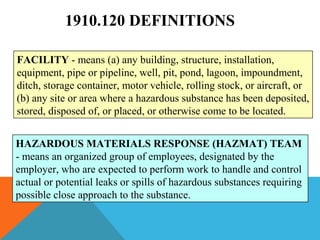

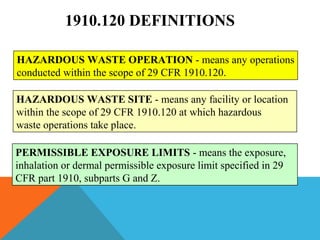

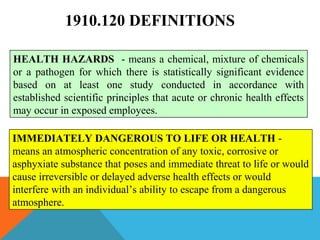

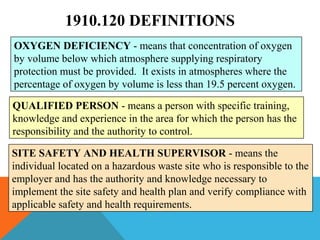

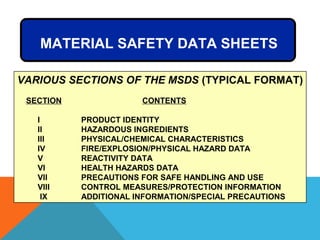

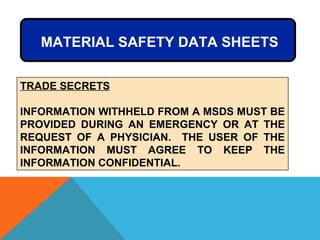

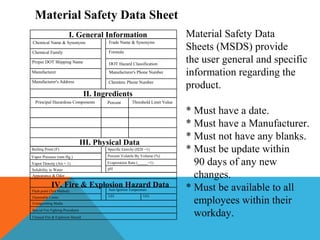

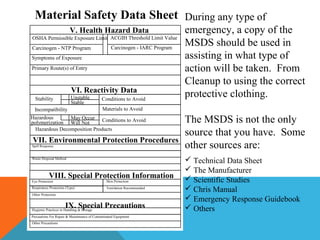

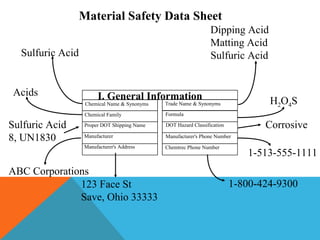

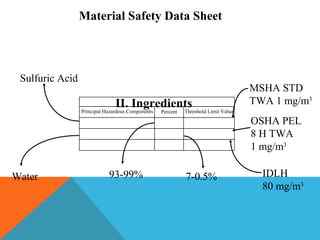

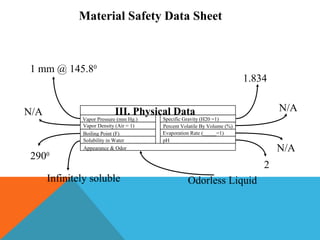

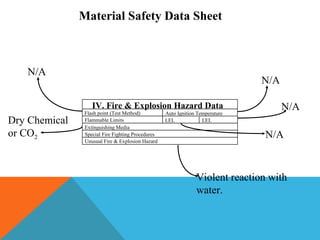

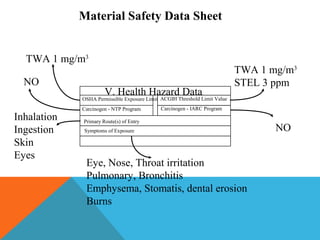

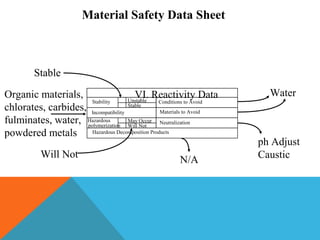

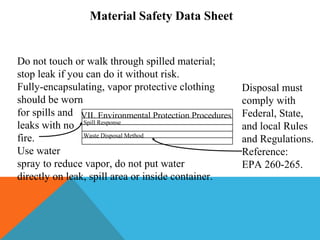

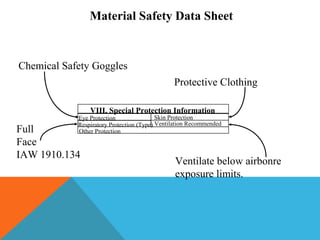

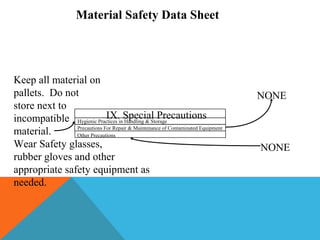

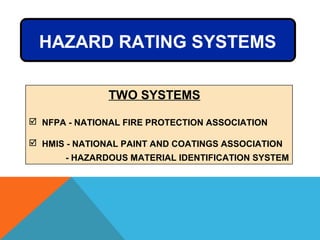

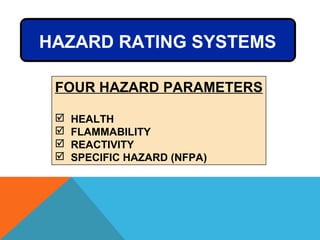

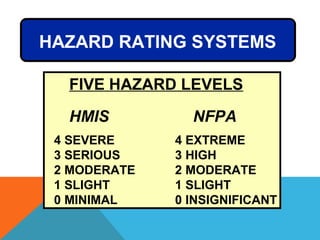

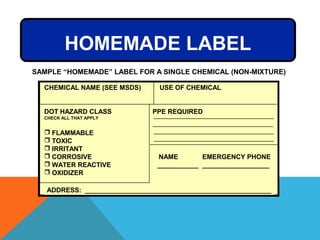

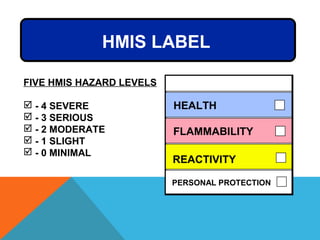

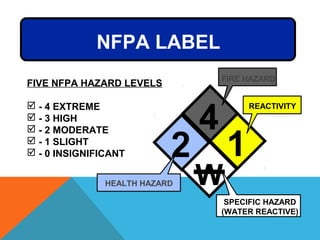

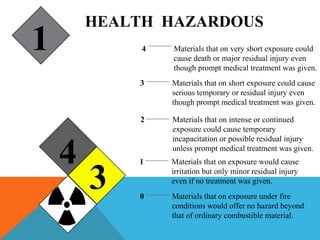

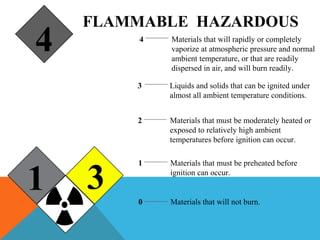

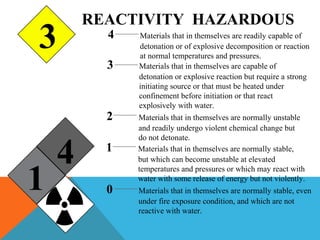

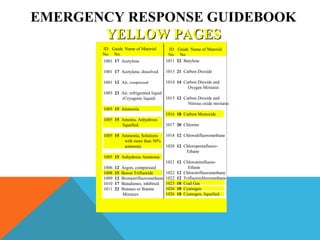

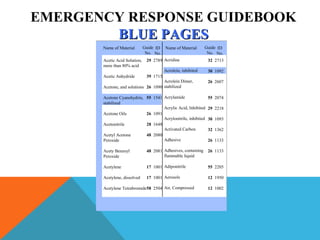

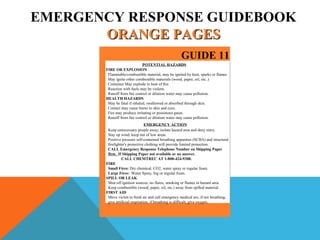

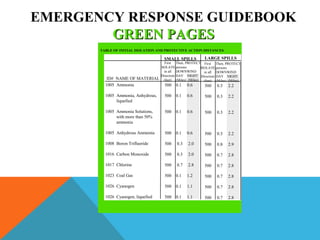

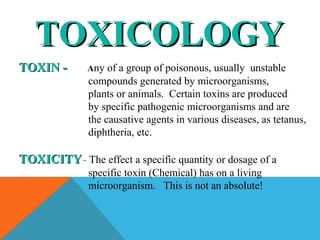

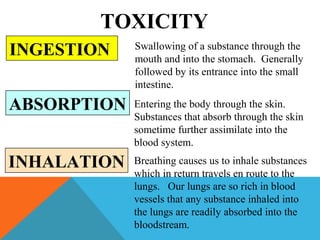

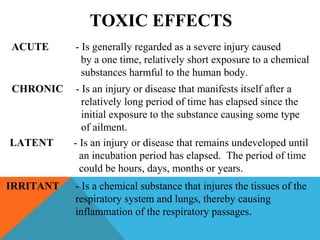

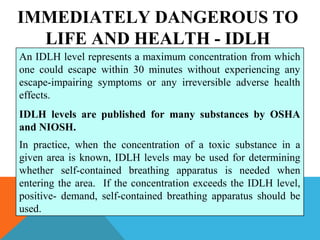

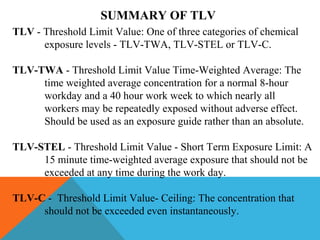

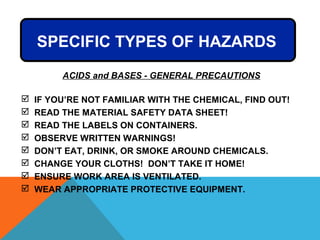

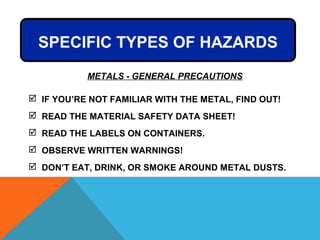

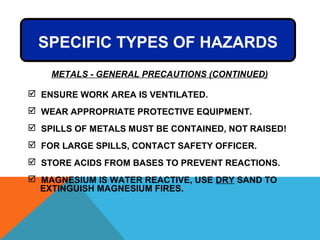

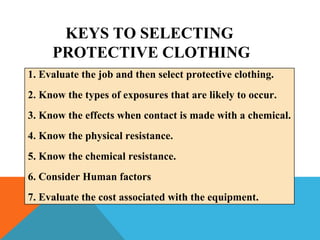

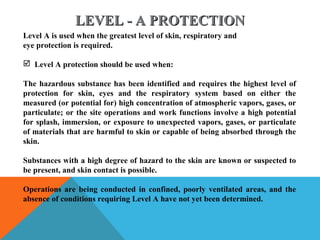

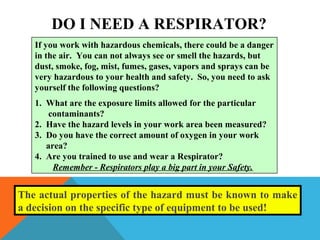

The document outlines the OSHA HAZWOPER training requirements for emergency response staff, focusing on the recognition and control of occupational hazards related to hazardous waste operations. It specifies the levels of training—from first responder awareness to on-scene incident commander—and stresses the importance of program implementation and safety standards to protect employees from recognized hazards. The document also includes definitions of key terms, regulatory standards, and the necessity of maintaining Material Safety Data Sheets (MSDS) for hazardous materials.