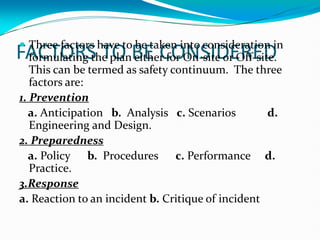

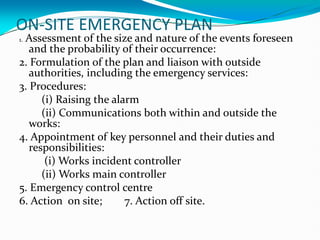

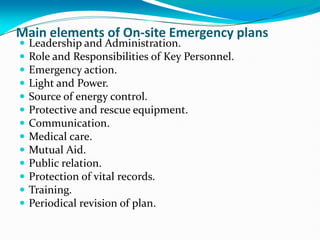

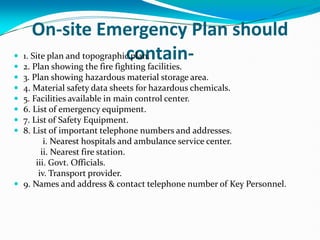

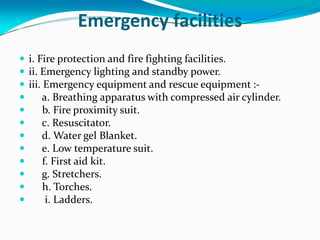

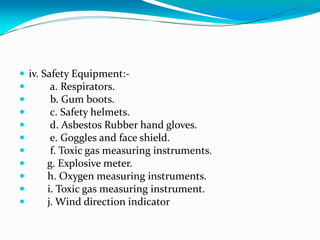

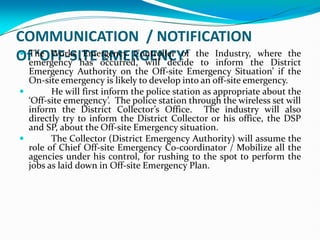

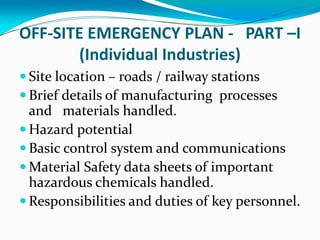

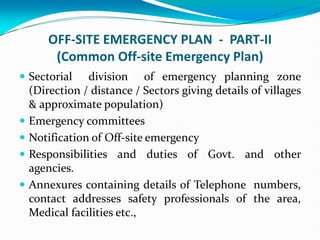

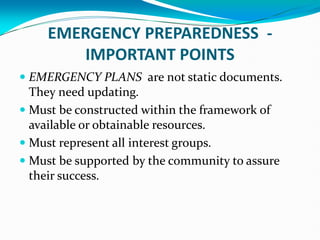

The document outlines the statutory requirements for on-site and off-site emergency plans for industrial occupiers, emphasizing the need for detailed disaster control measures and responsible personnel. It addresses various types of emergencies, factors for plan formulation, and key personnel responsibilities, including communication and medical support roles. The document also underscores the importance of preparedness, response strategies, and continual updates to emergency plans to ensure effective handling of potential hazardous incidents.