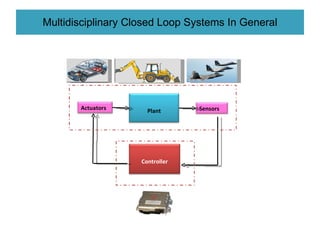

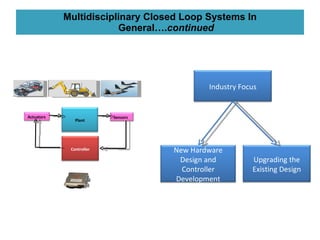

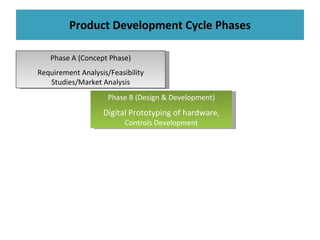

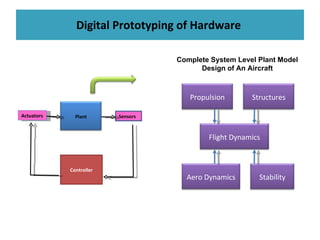

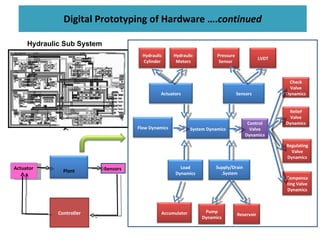

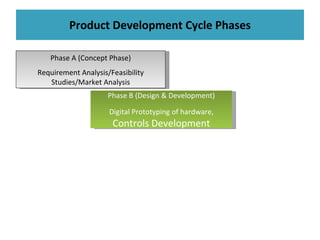

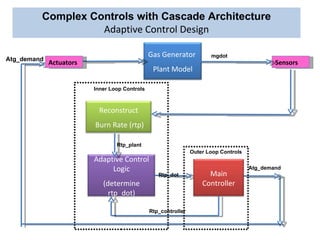

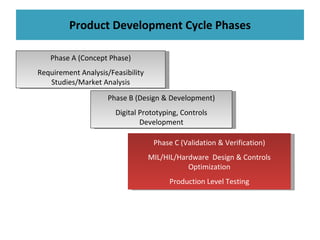

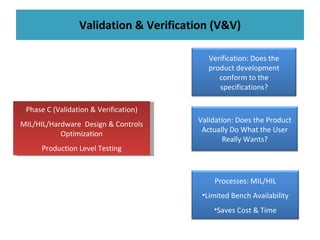

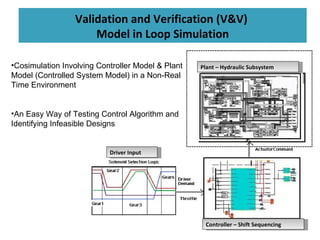

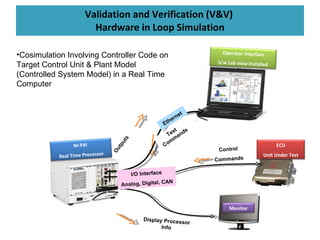

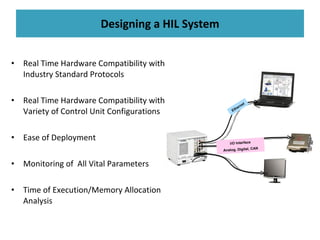

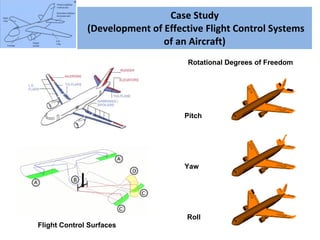

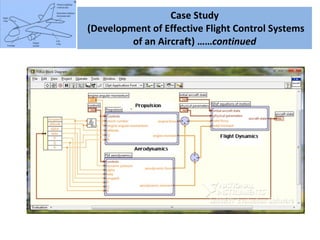

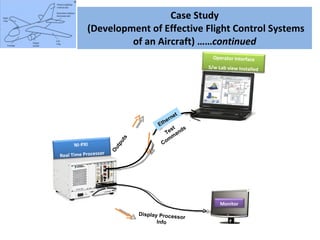

This document discusses the multidisciplinary product development cycle and deployment of NI-PXI real-time hardware in hardware-in-the-loop simulations. It describes the typical phases of product development including concept, design and development, and validation and verification. It also provides details about using digital prototyping, model-in-the-loop and hardware-in-the-loop simulations using NI-PXI real-time hardware to test control algorithms and identify issues before full deployment. A case study on developing effective flight control systems for an aircraft is presented as an example.