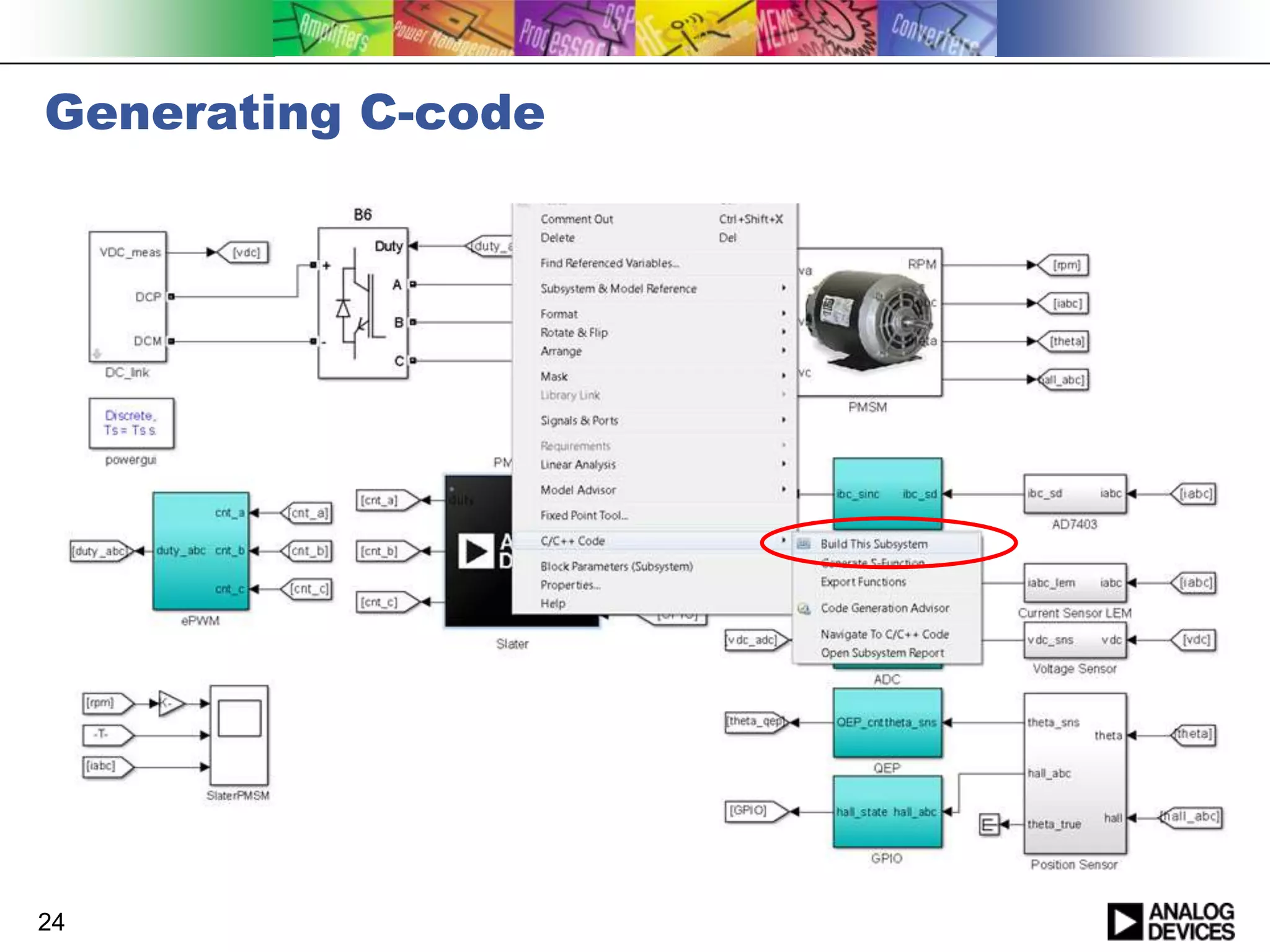

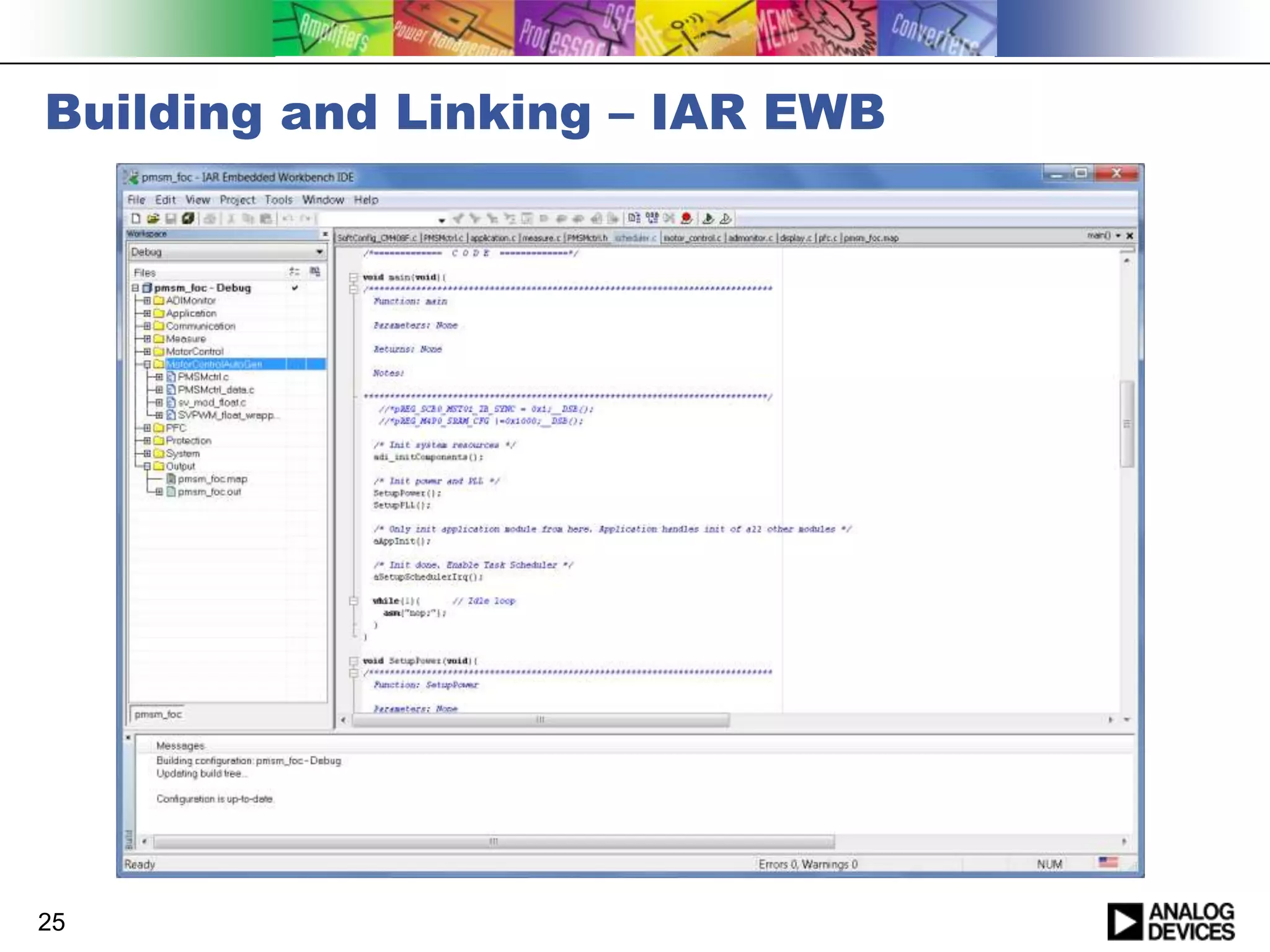

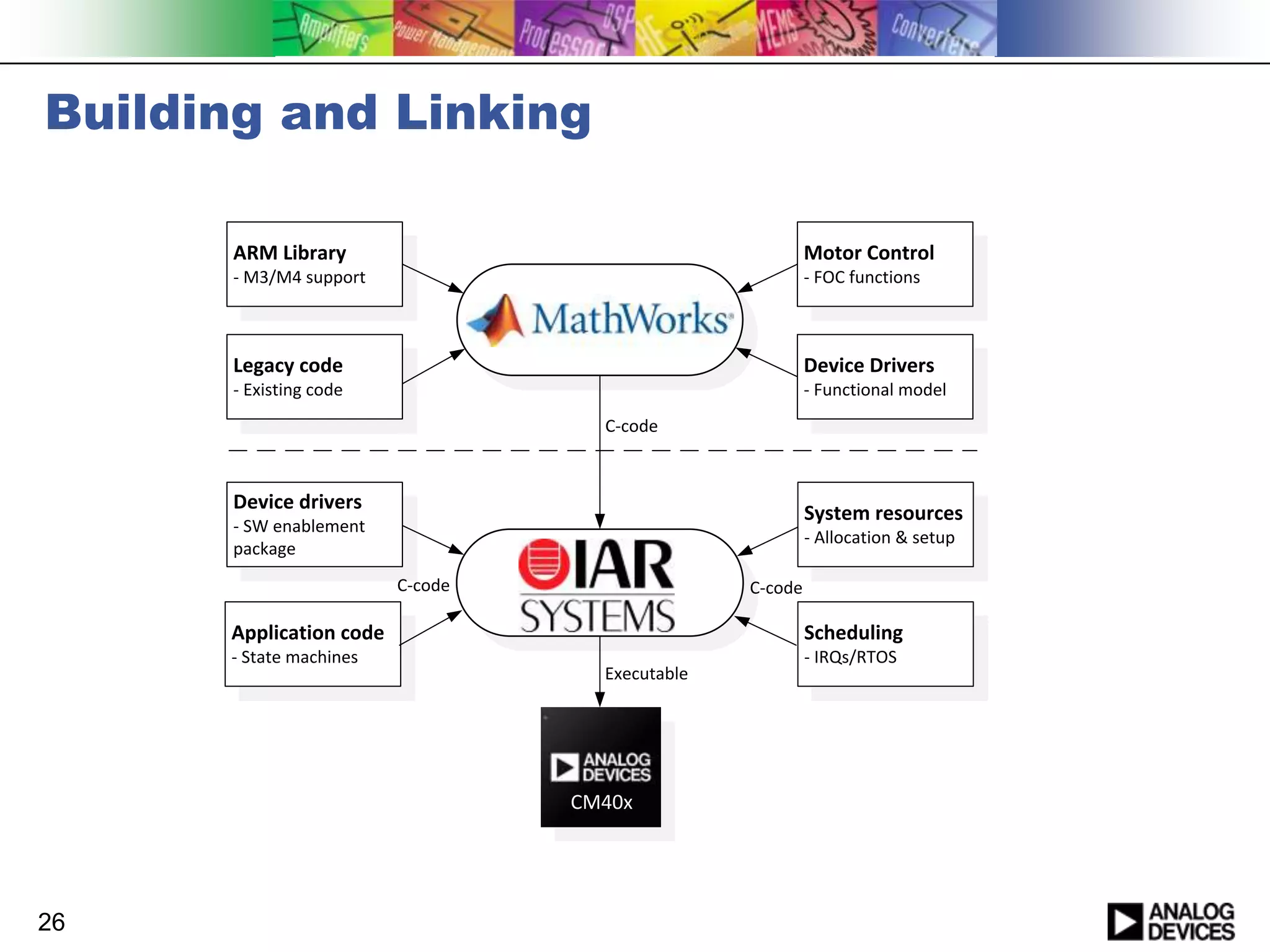

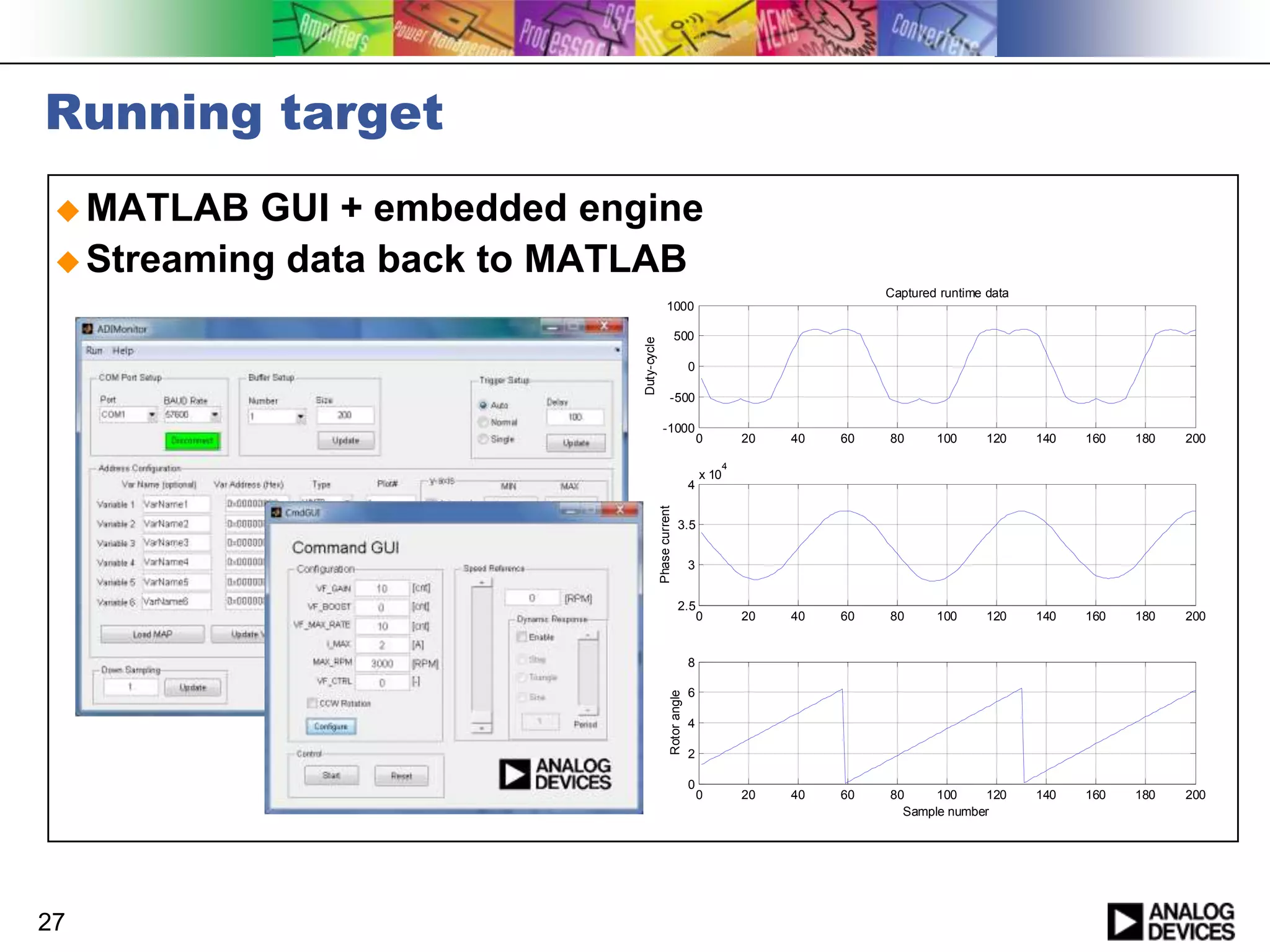

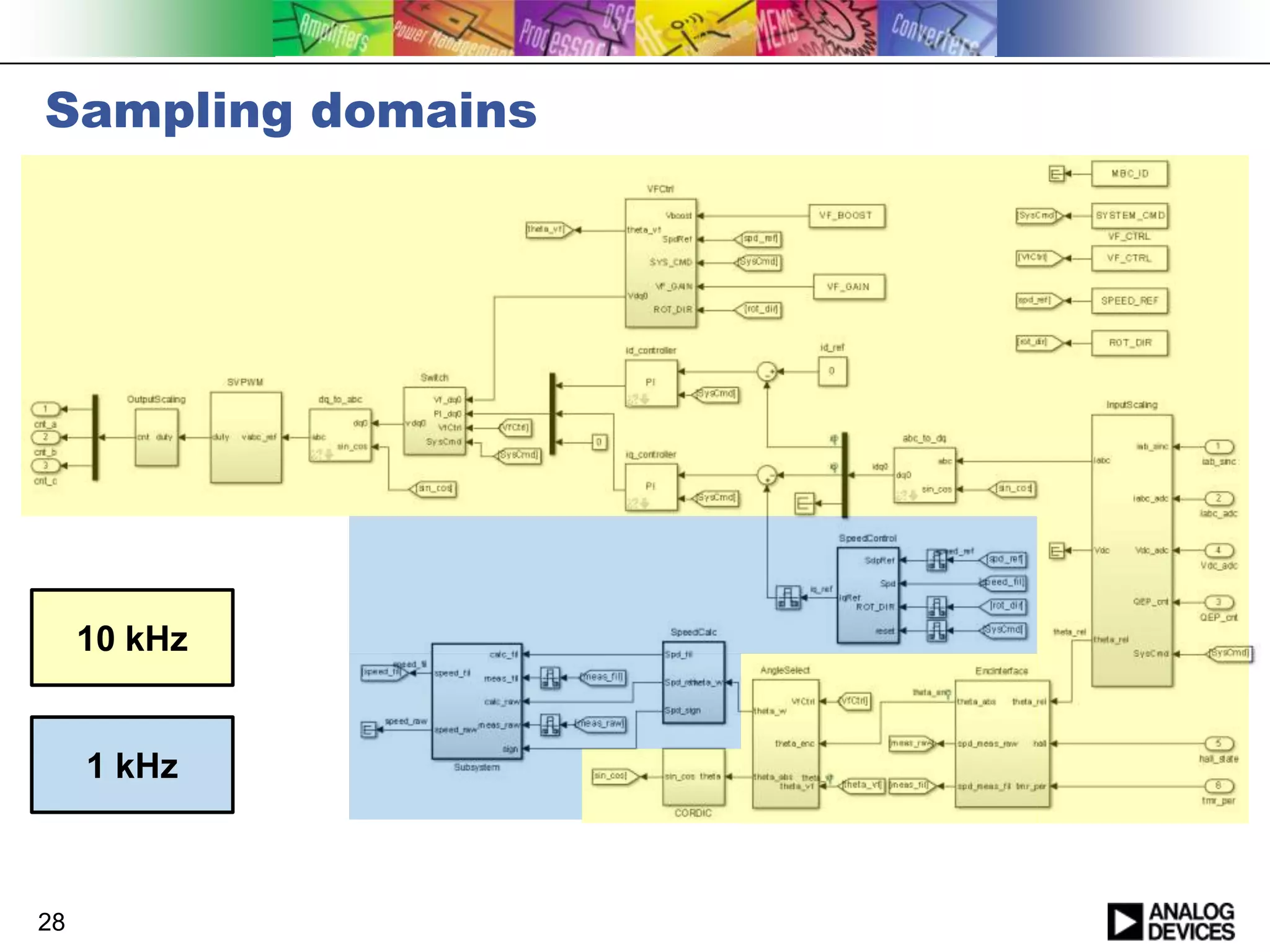

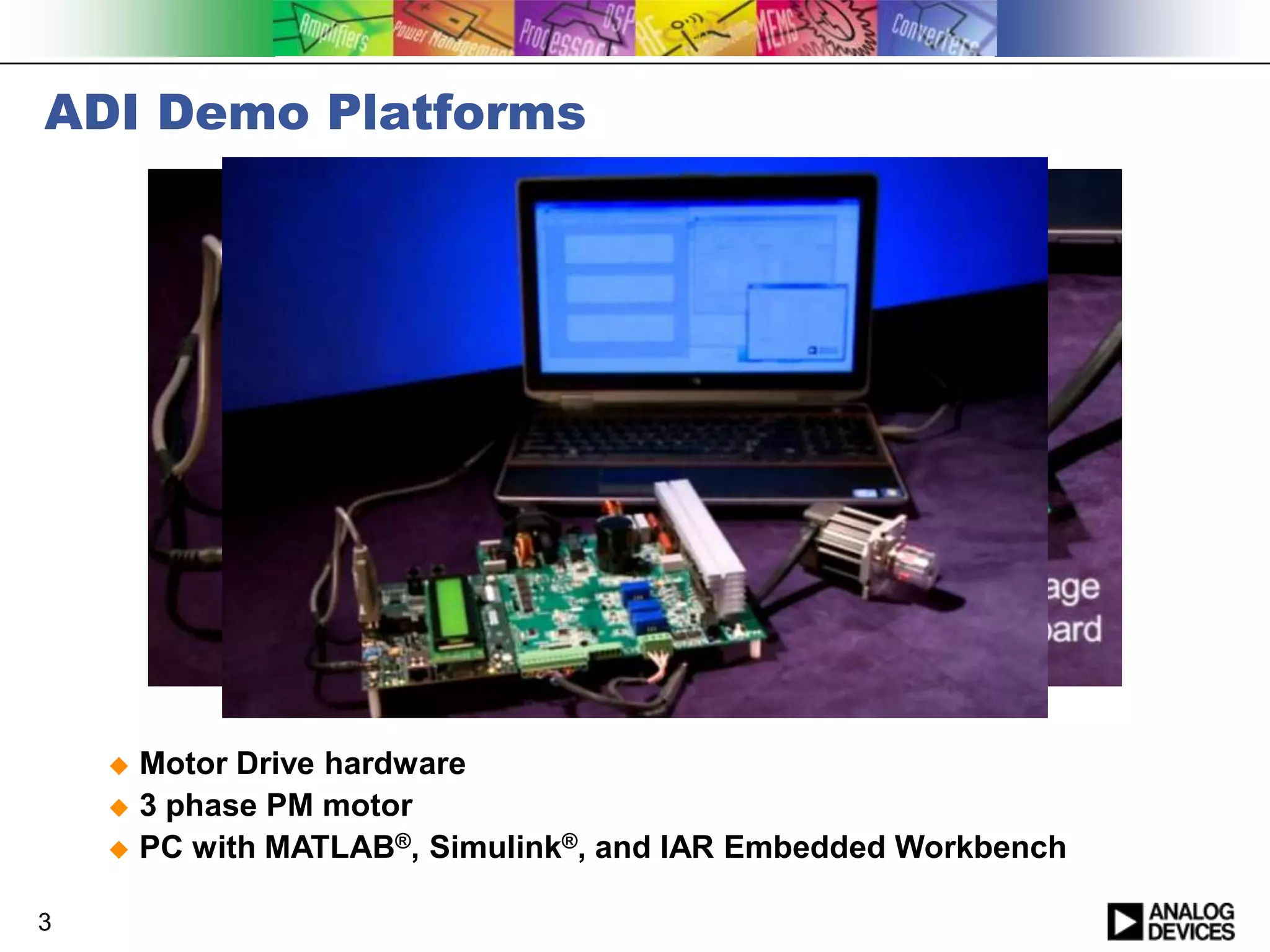

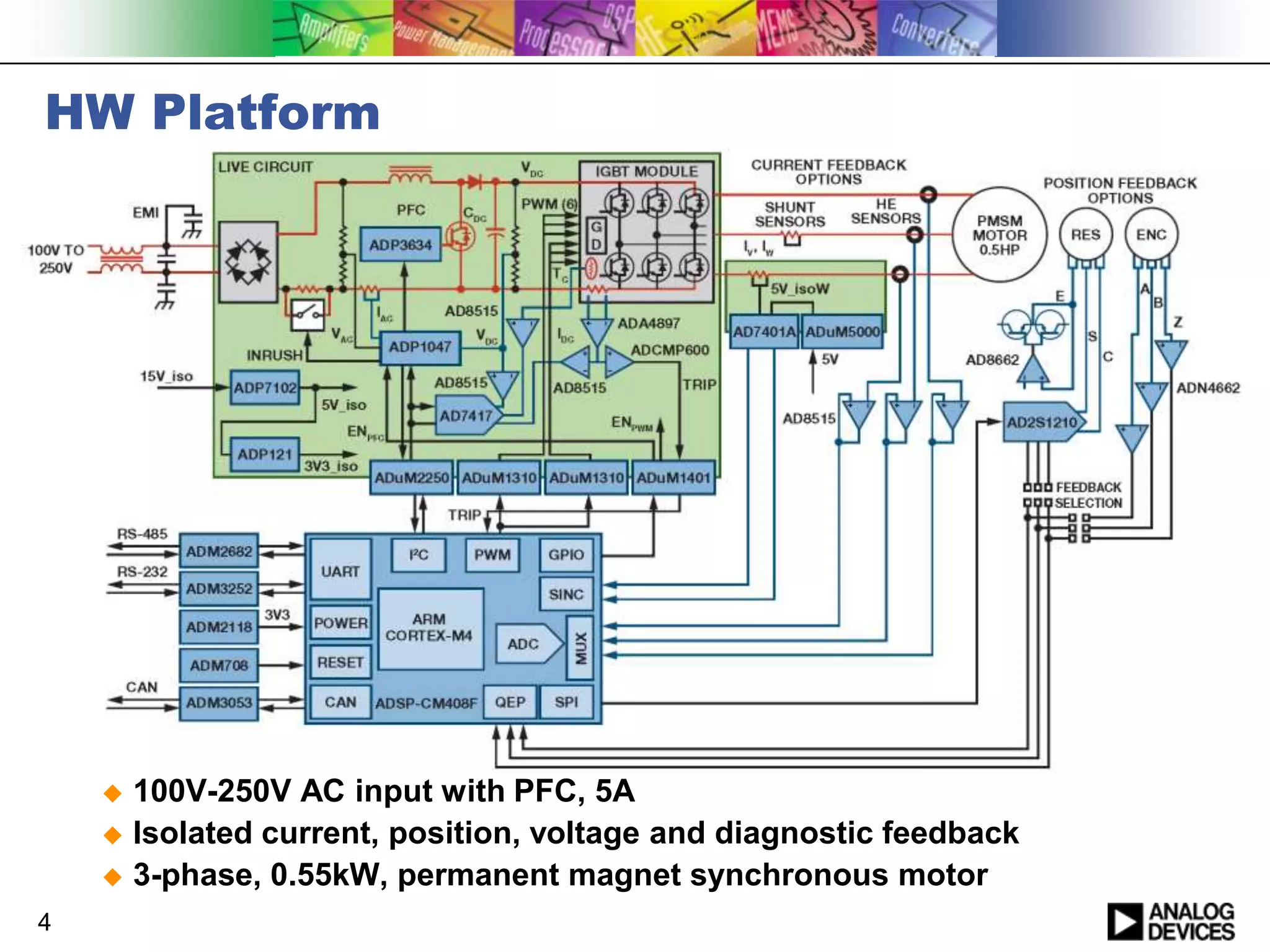

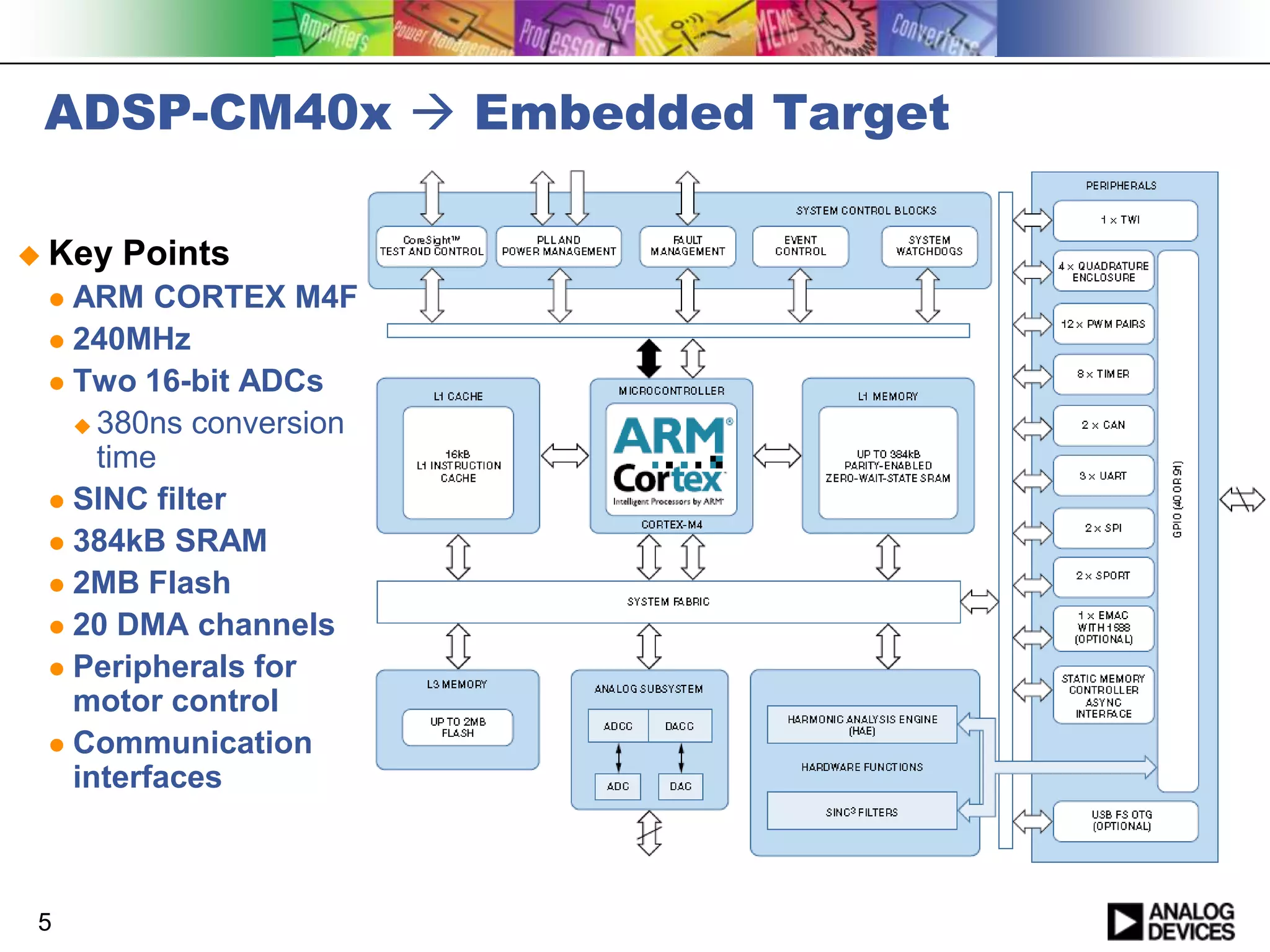

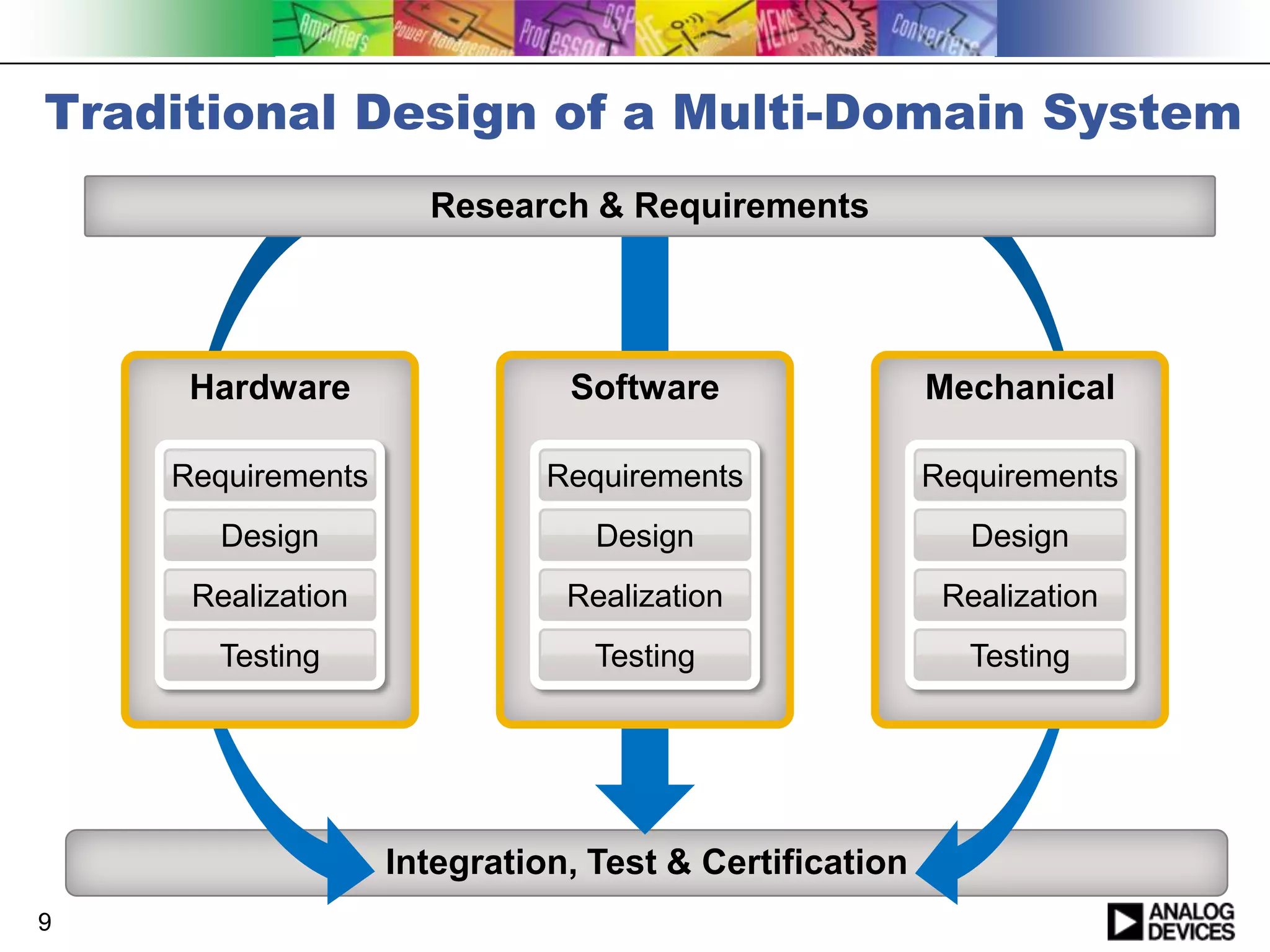

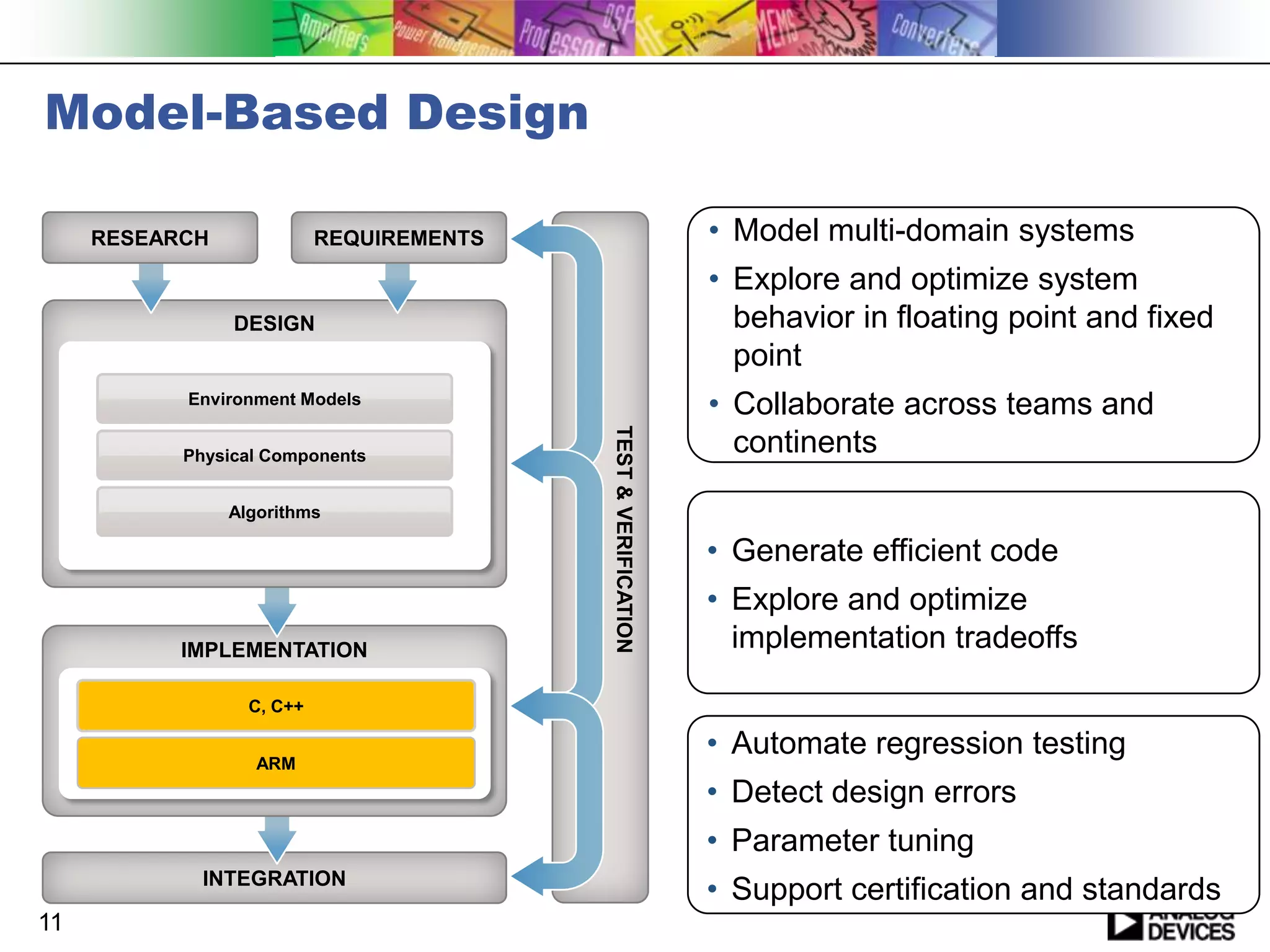

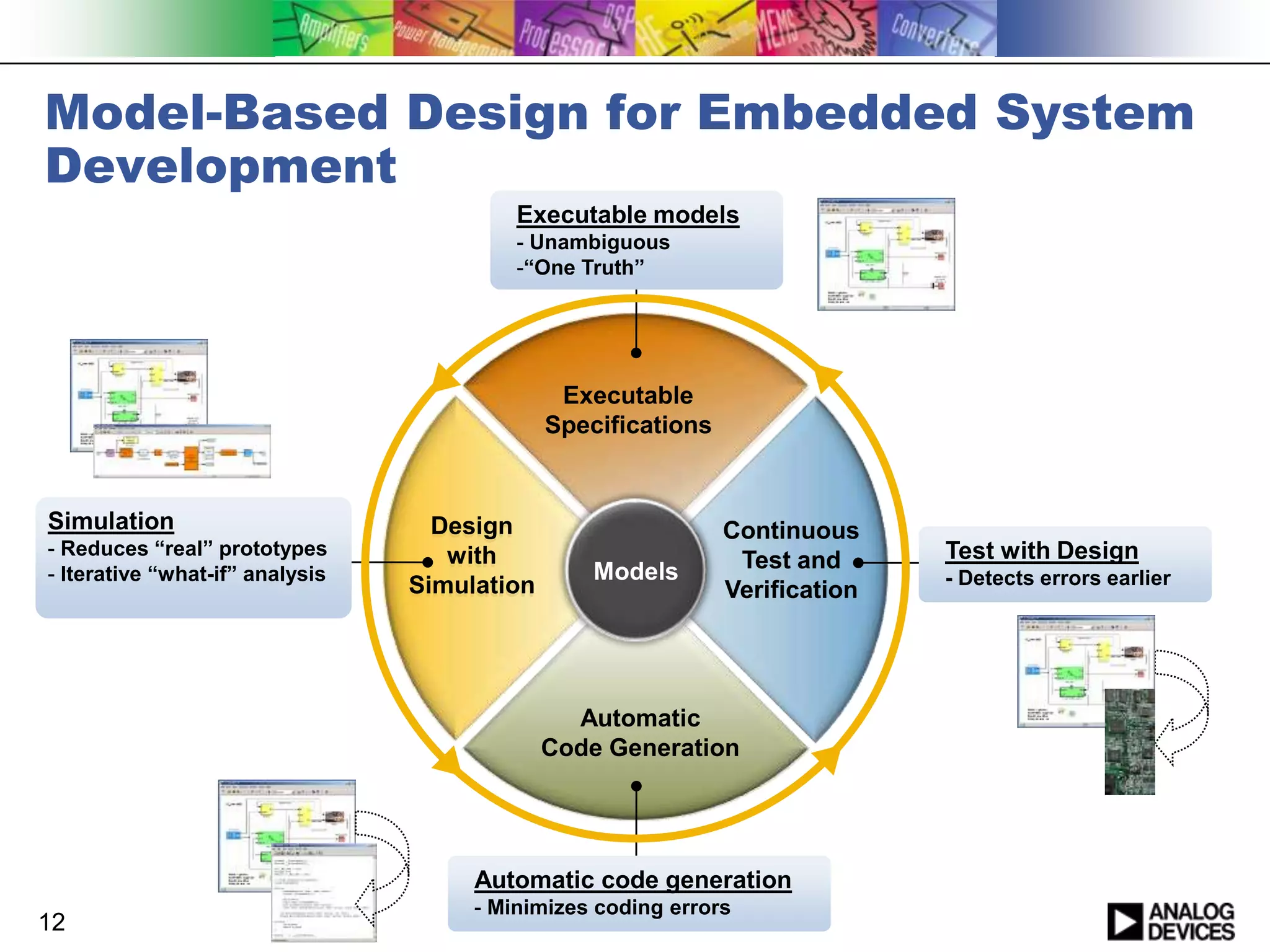

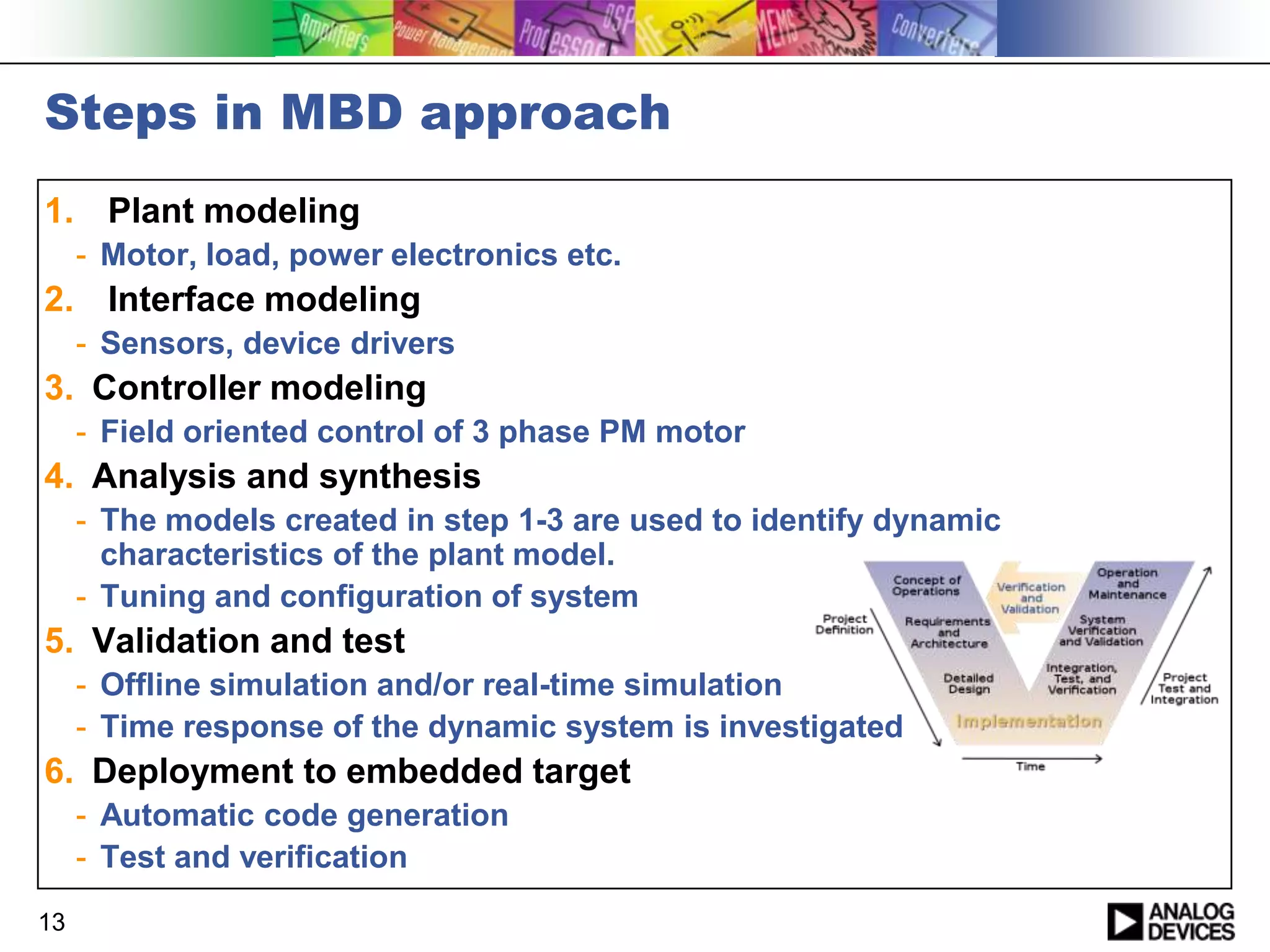

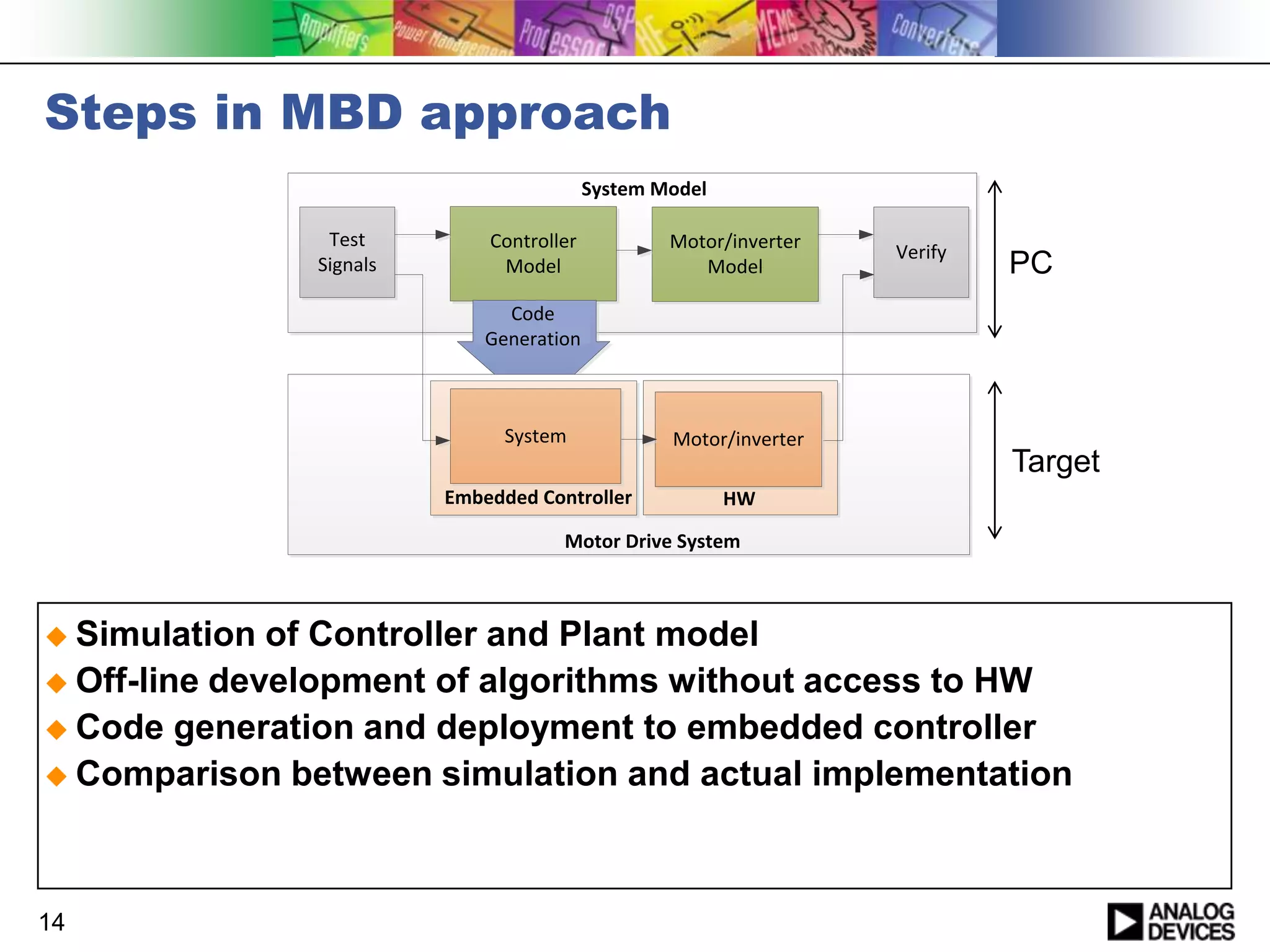

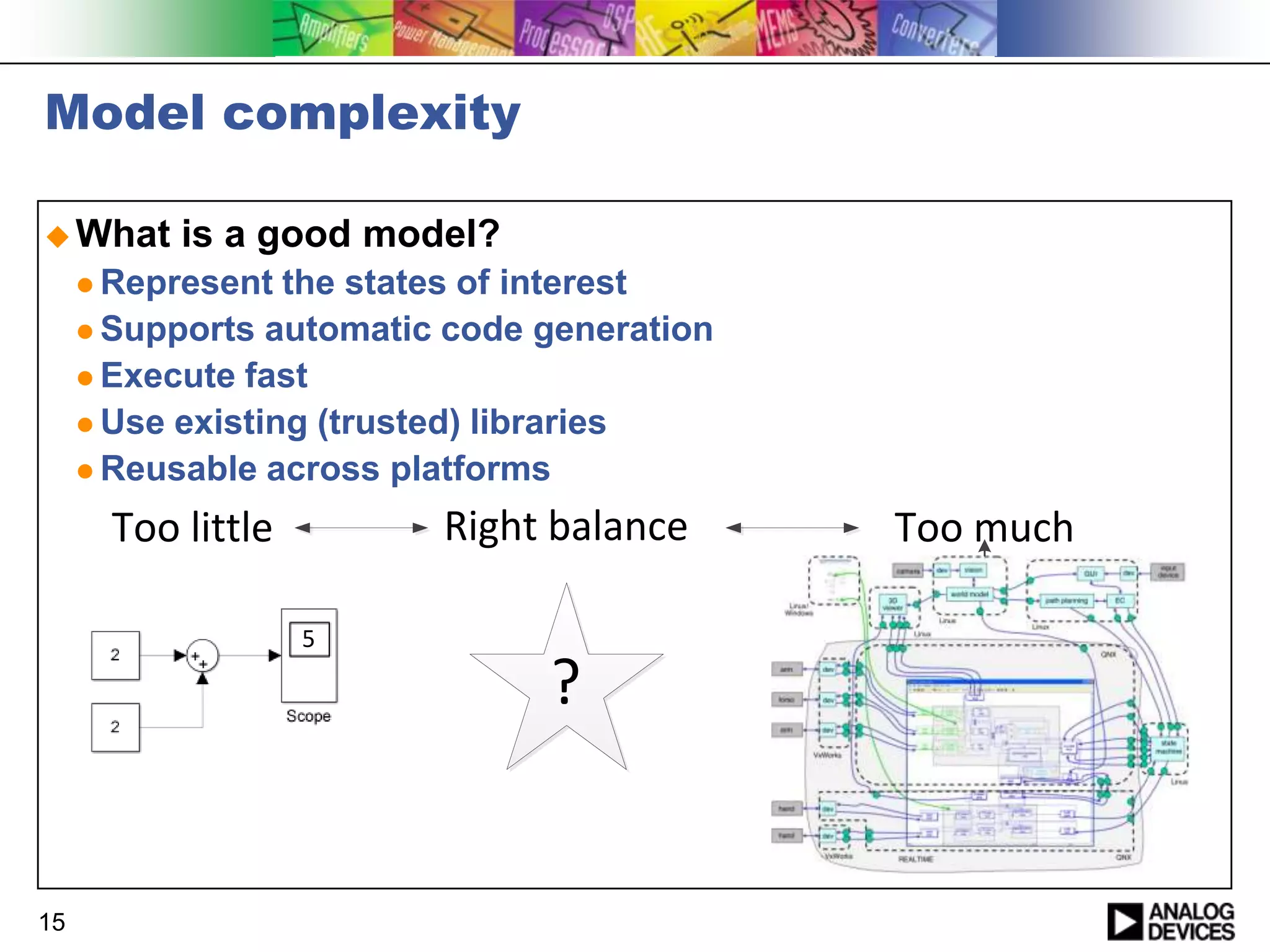

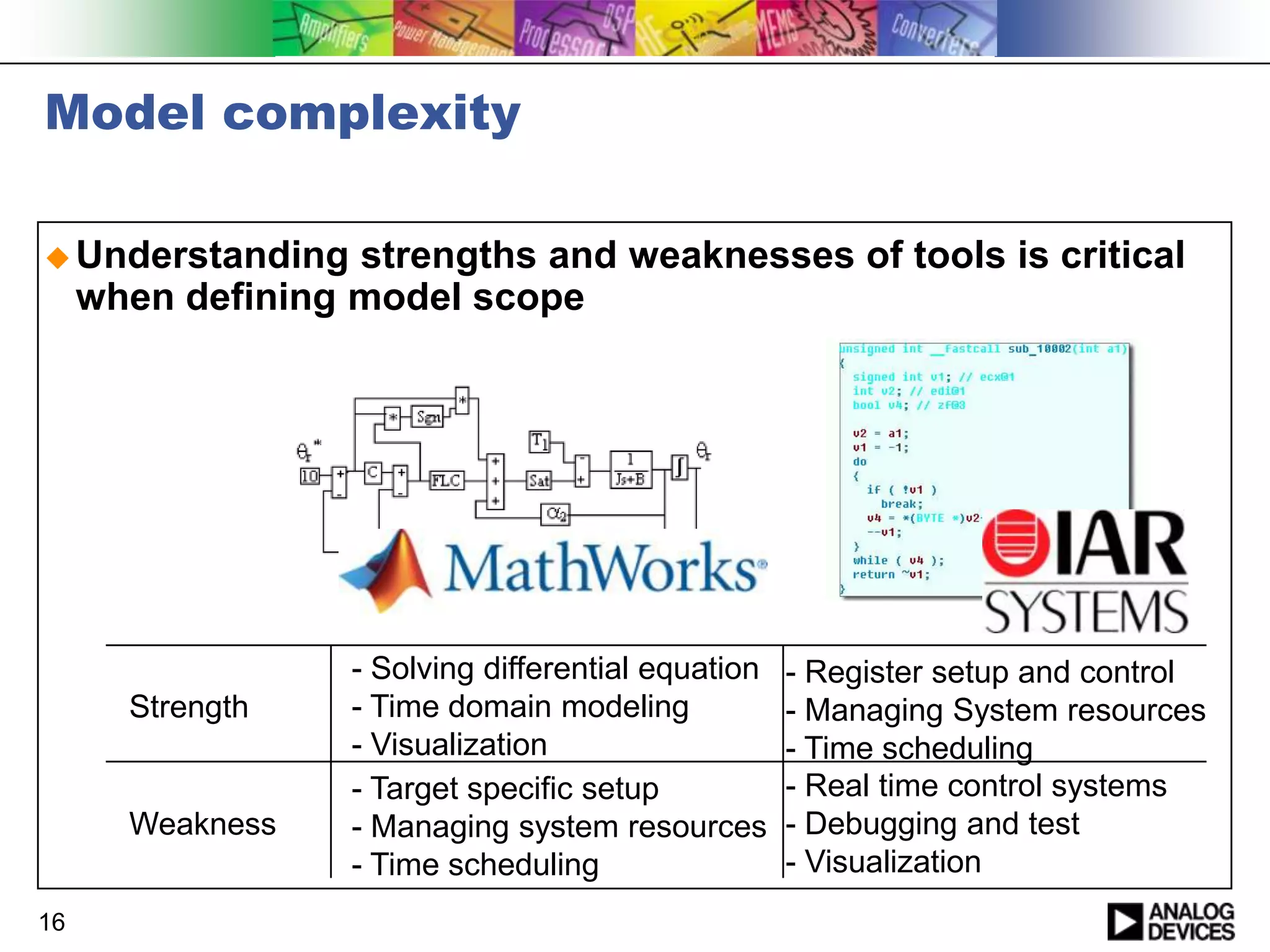

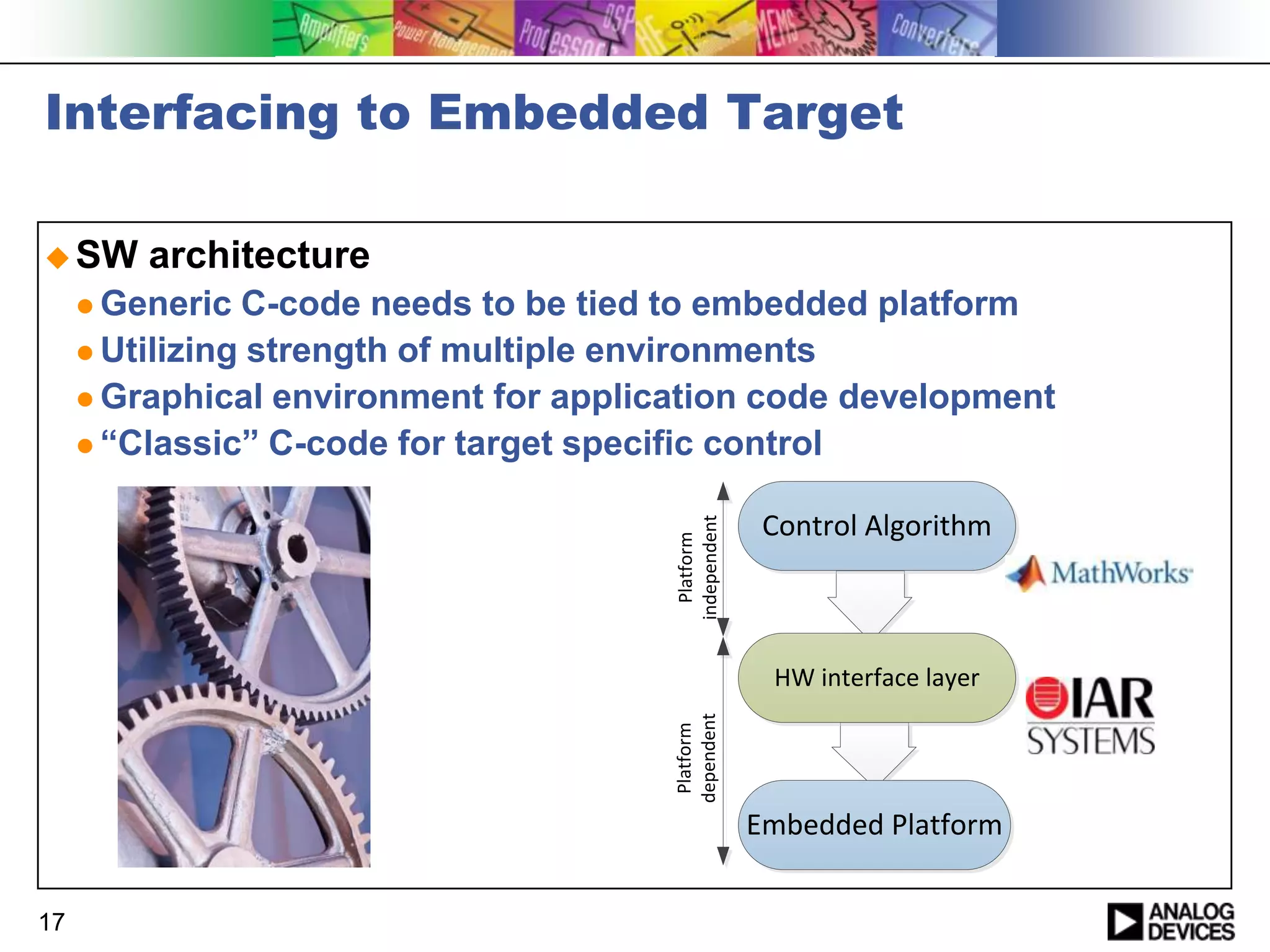

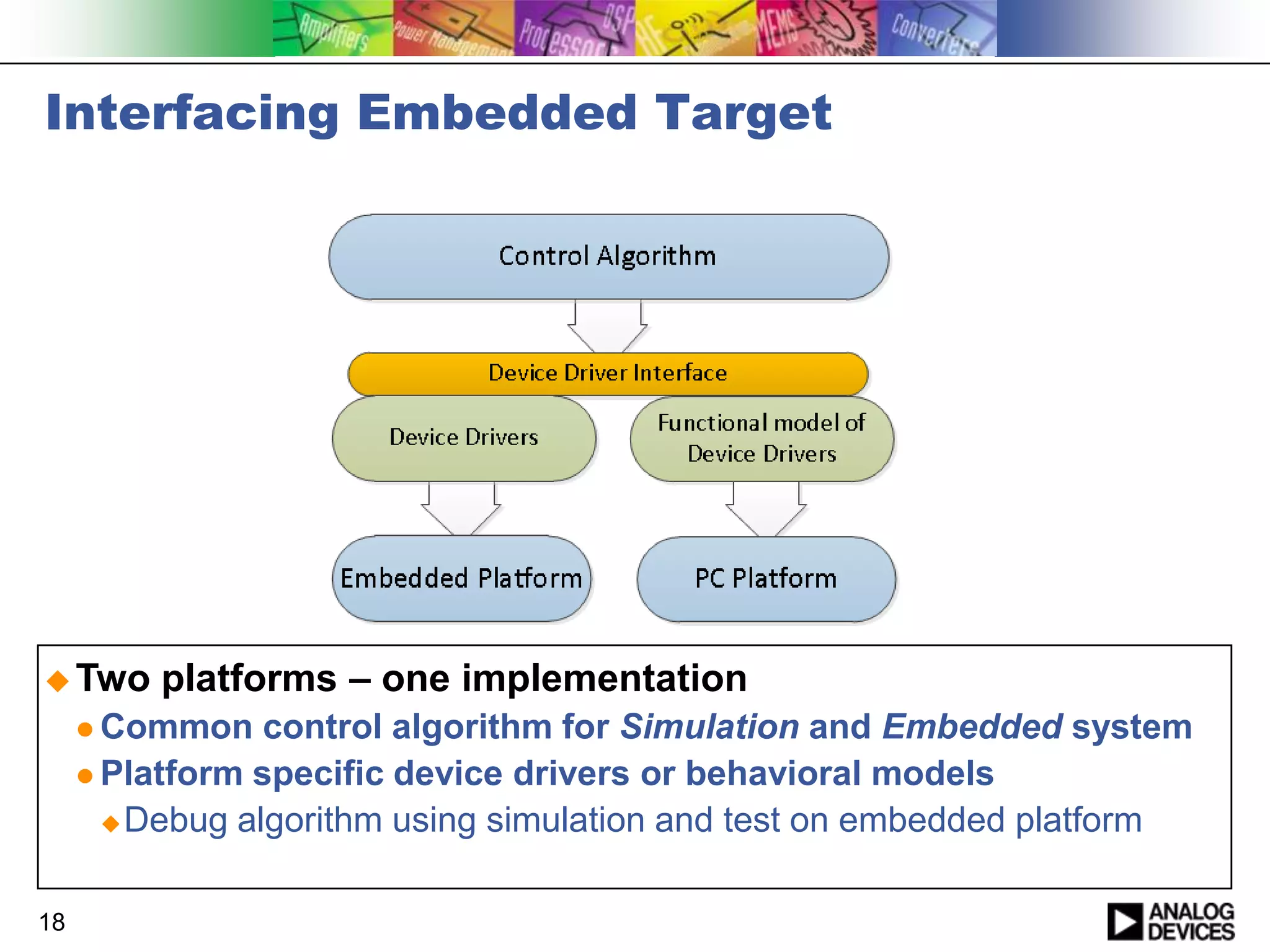

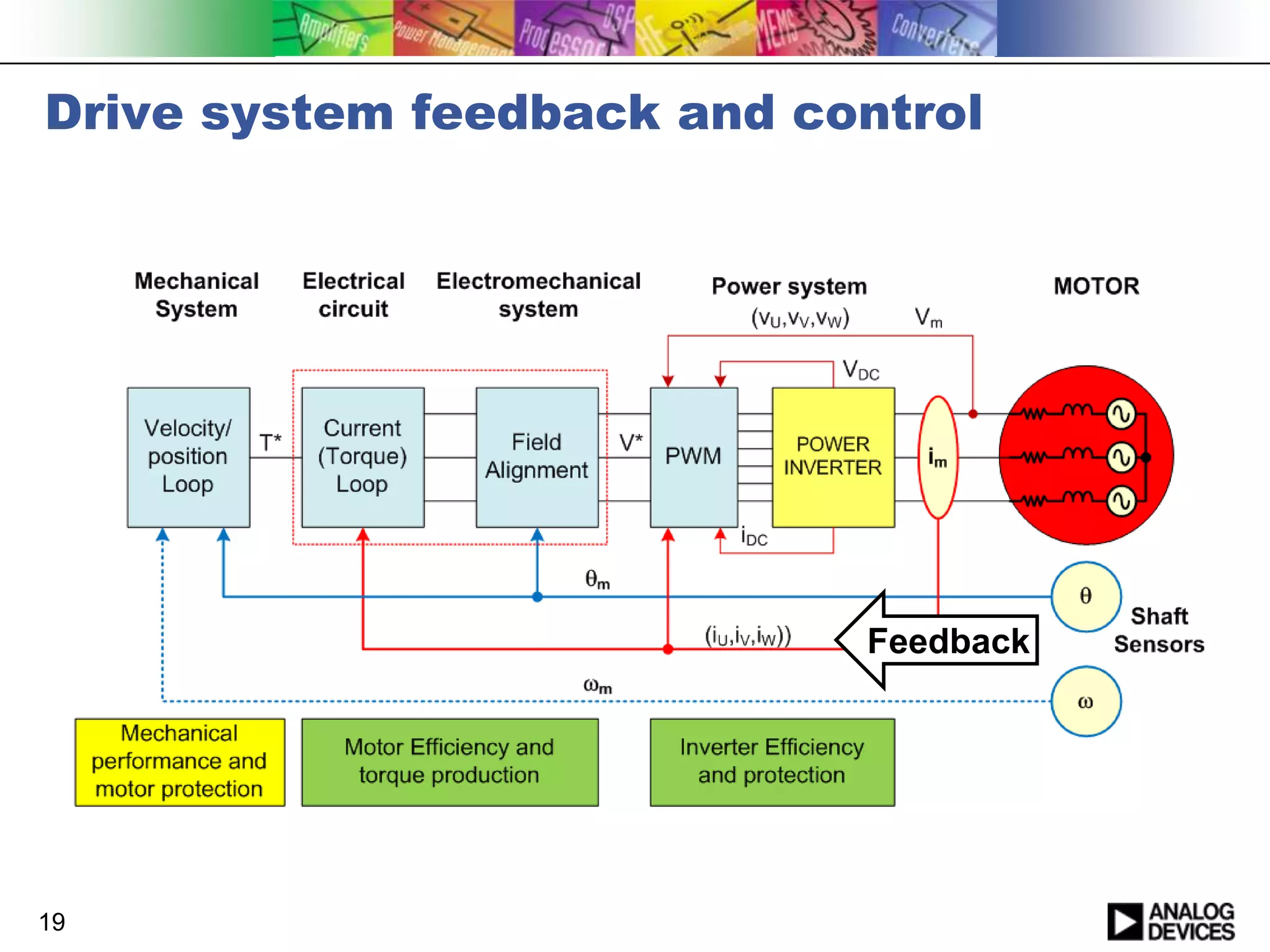

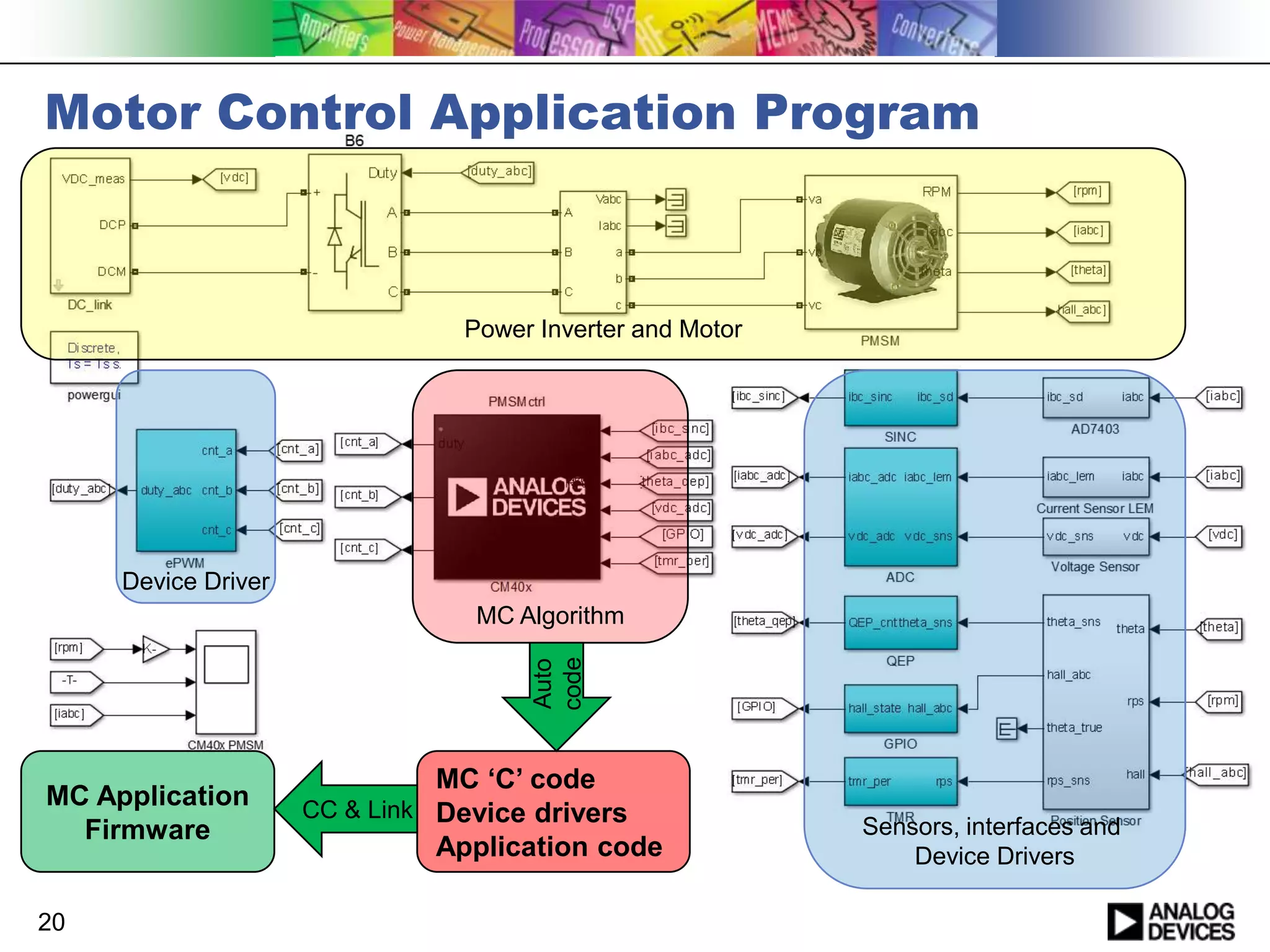

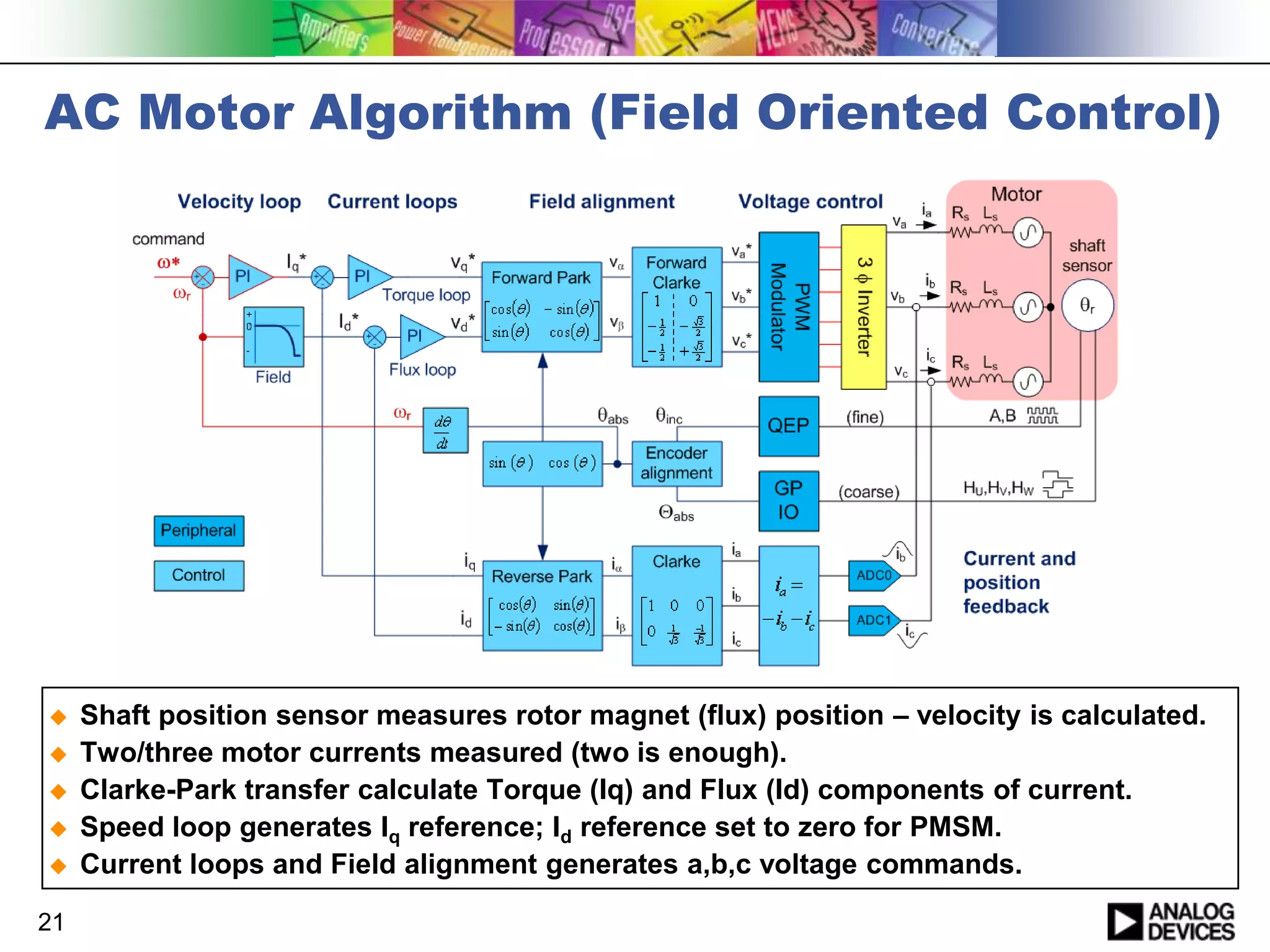

The document discusses model-based design for developing motor control applications. It describes modeling motor control systems using Simulink, simulating the models to analyze system behavior, and automatically generating C code to run on an embedded platform. Key aspects covered include modeling the motor, electronics, interfaces and control algorithm, generating generic C code, and interfacing this code to the embedded target using device drivers. The approach allows debugging the application through offline simulation and testing on the embedded hardware in real-time.

![Simulation

Simulink scopes

Code debugging

Data analysis in MATLAB

Magnitude [dB]

0

-50

-100

-150

-200

-250

0

1000

2000

3000

Frequency [kHz]

4000

5000

0

1000

2000

3000

Frequency [kHz]

4000

5000

Phase [Degrees]

0

-1000

-2000

-3000

23](https://image.slidesharecdn.com/mbdembeddedworld-140305141020-phpapp02/75/Model-Based-Design-For-Motor-Control-Development-23-2048.jpg)