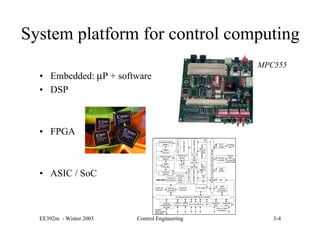

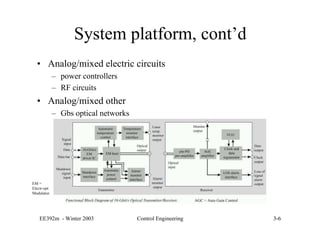

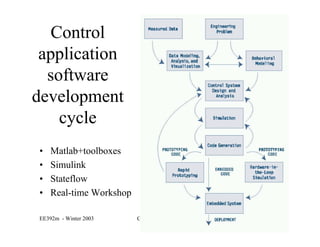

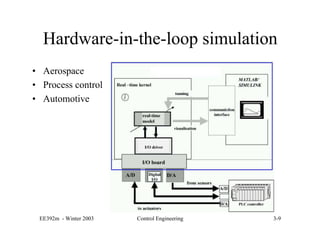

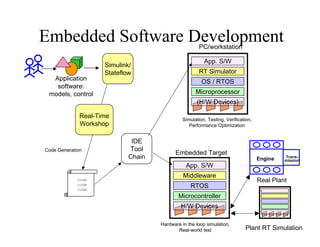

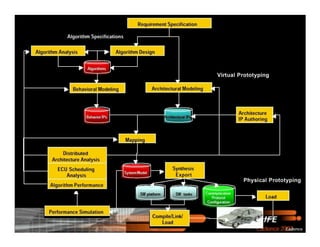

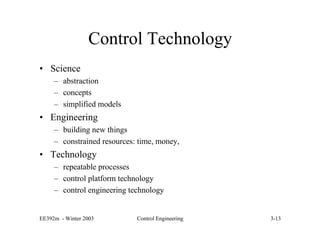

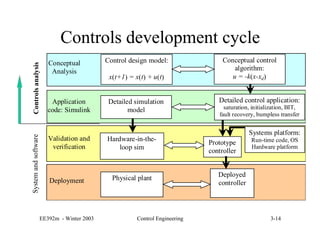

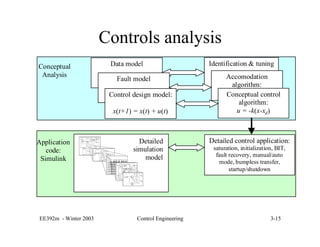

The document outlines the principles of model-based control engineering, detailing the development steps from modeling to validation across various platforms and applications. It emphasizes the need for a generalized approach suitable for diverse systems including automotive, aerospace, and industrial applications. Key topics include the control development cycle, specific control technologies, and emerging applications in fields like biomedical and finance.