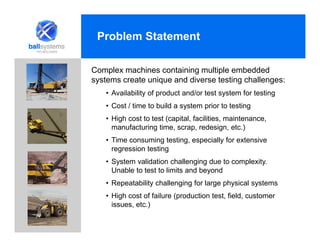

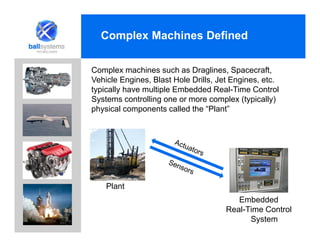

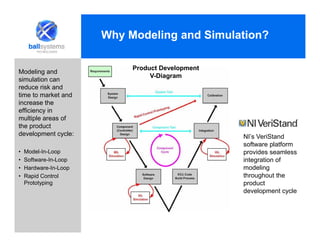

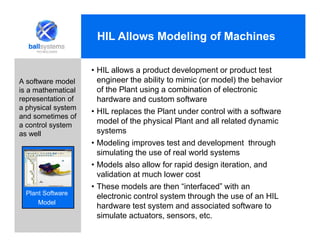

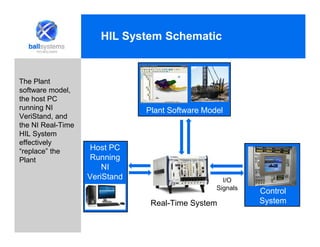

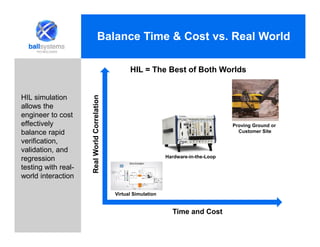

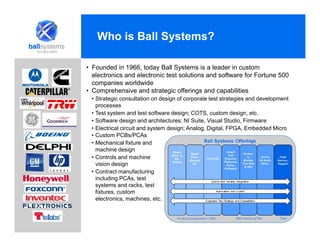

The document discusses modeling and simulation techniques like Hardware-in-the-Loop (HIL) testing that can help test complex machines with multiple embedded systems more efficiently by replacing physical components with software models, allowing tests that would be too risky, expensive, or time-consuming with physical systems; it also introduces Ball Systems as an expert in HIL testing and modeling who can help clients develop HIL strategies, systems, software, and models to validate products.