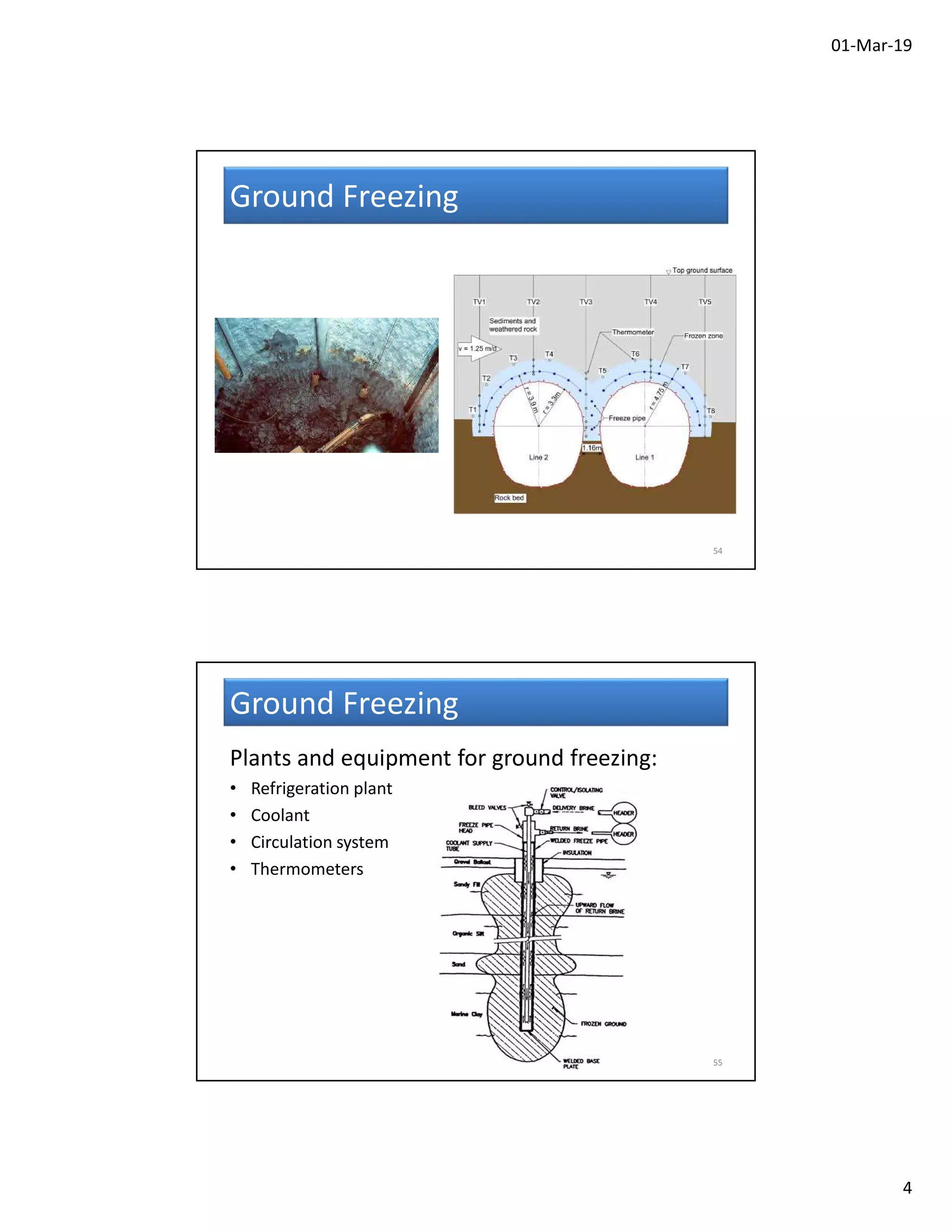

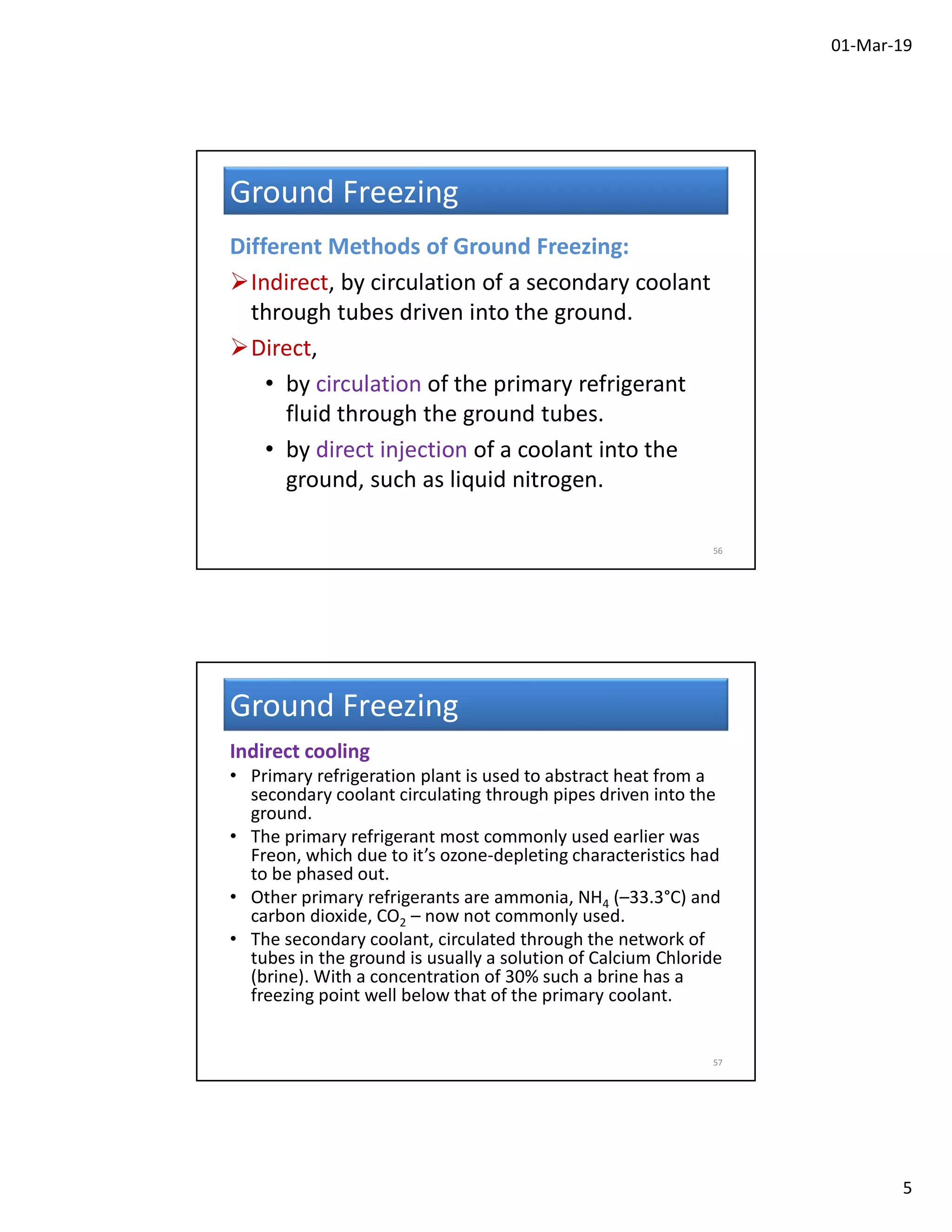

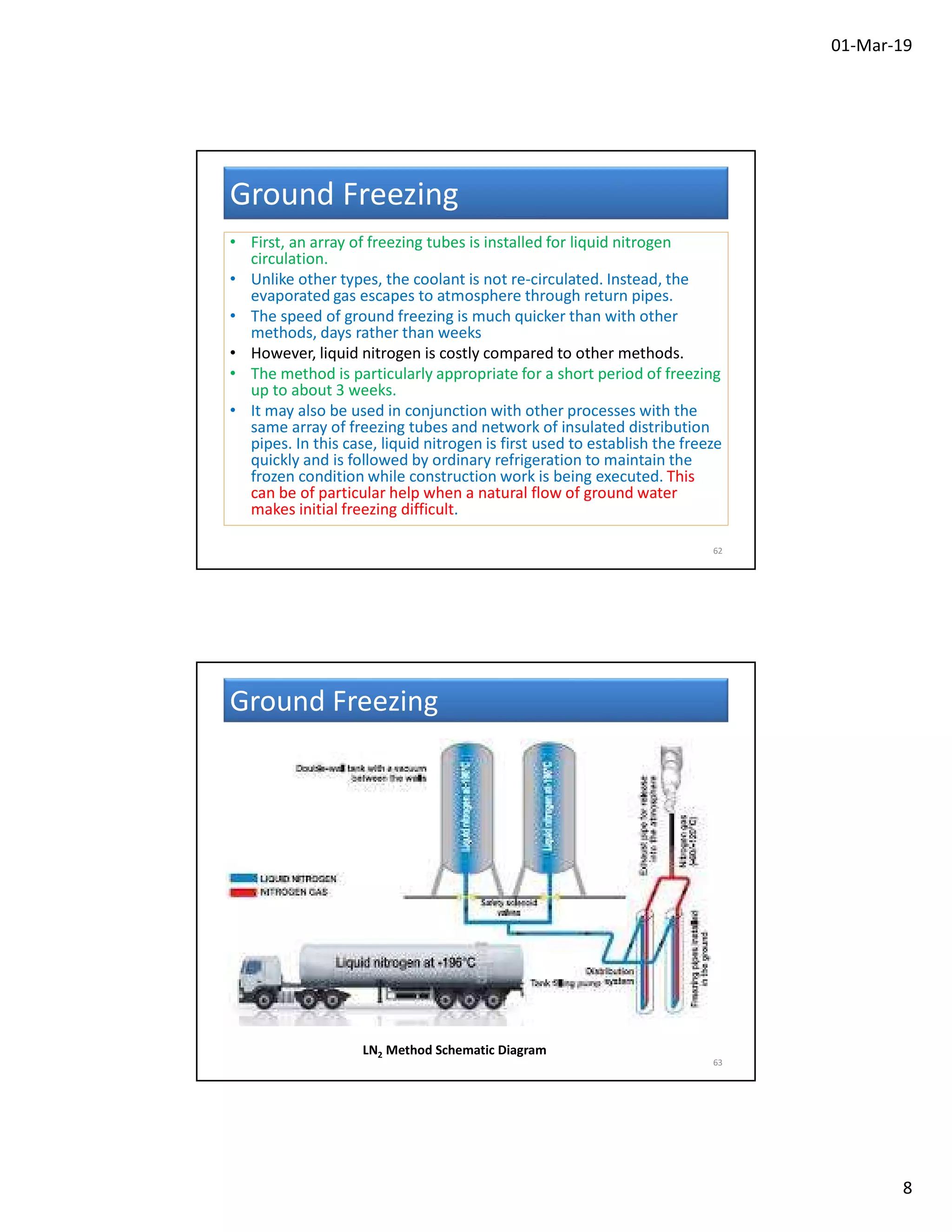

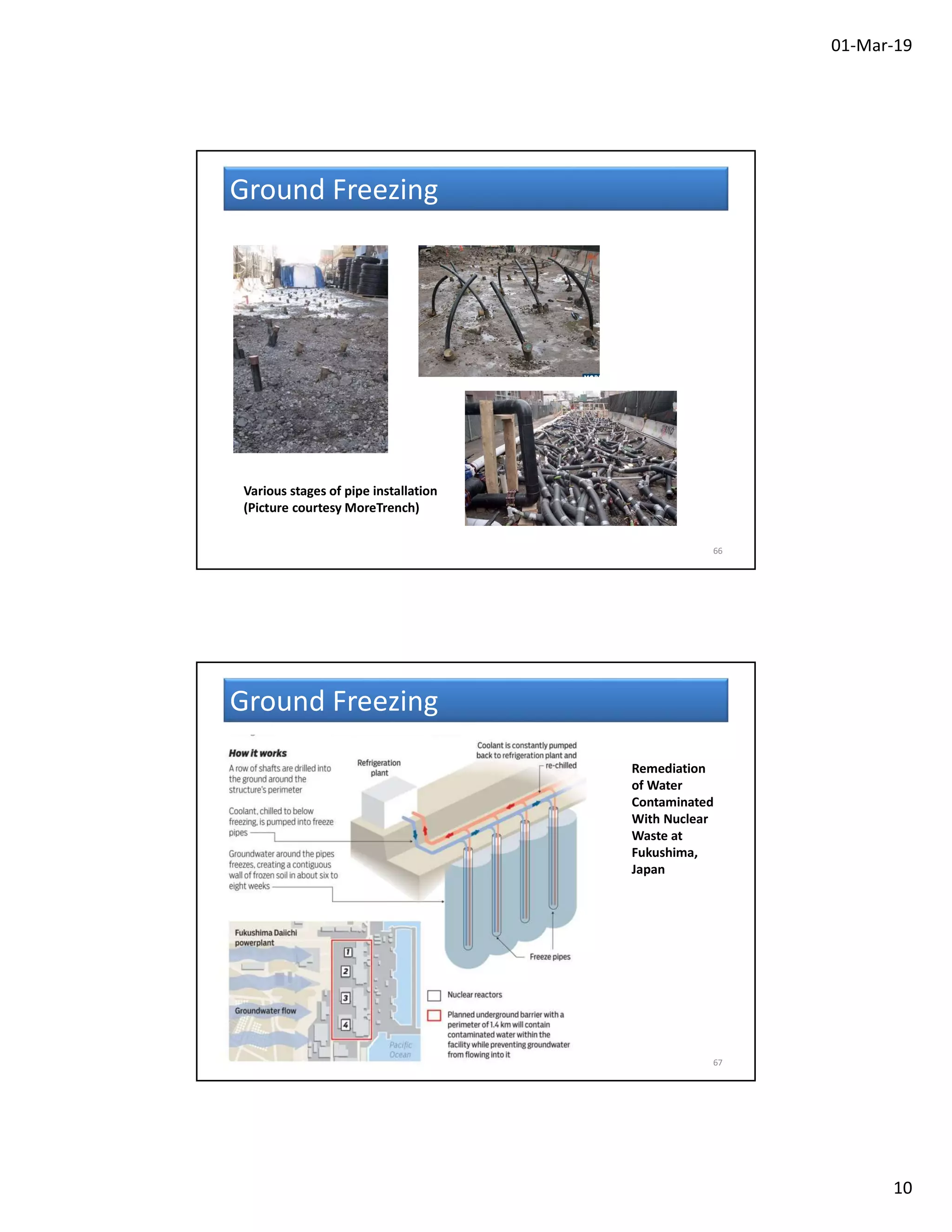

This document discusses ground freezing techniques used in construction projects. It describes how freezing the ground by circulating refrigerants through pipes increases soil strength and stops water seepage. Several methods are outlined, including indirect freezing using a secondary coolant and direct freezing of the primary refrigerant or liquid nitrogen directly into the soil. Applications include tunneling, excavations, shafts and temporarily stabilizing structures or containing waste. Diagrams illustrate the freezing process and equipment used.