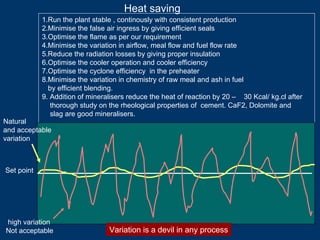

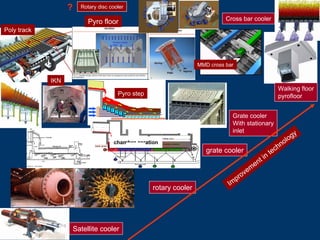

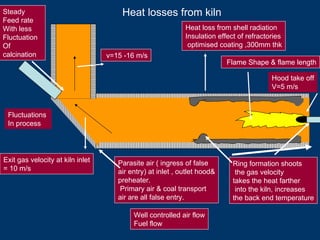

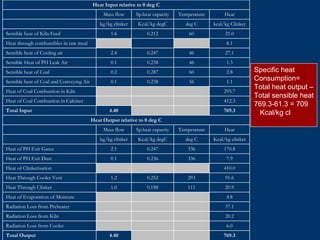

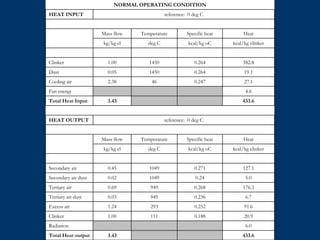

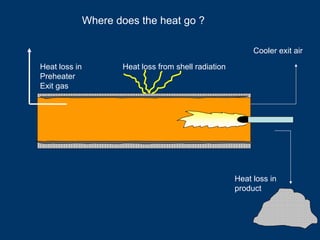

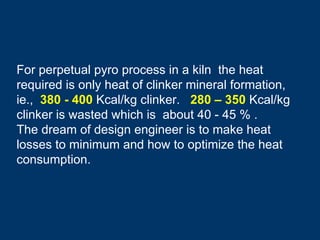

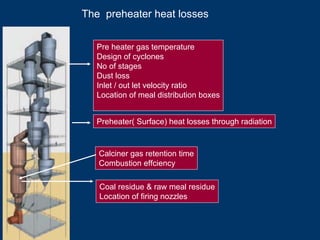

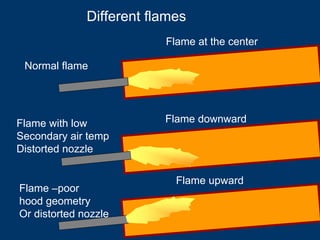

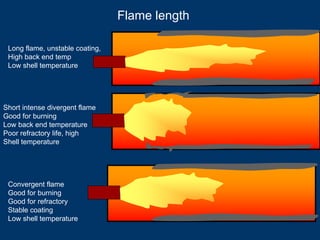

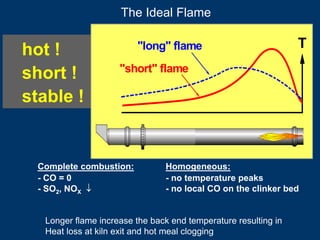

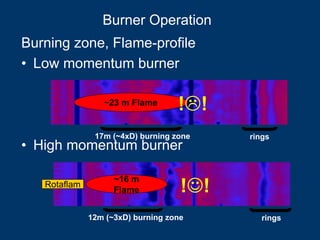

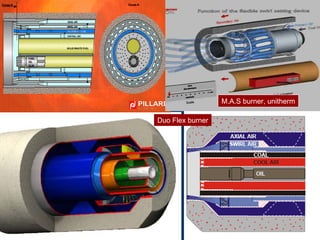

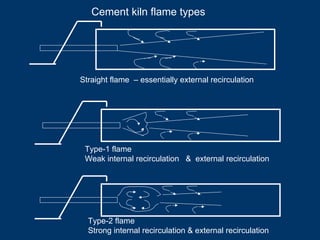

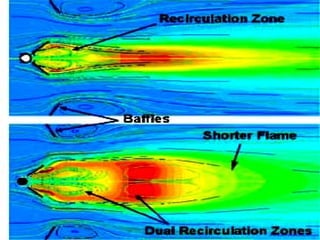

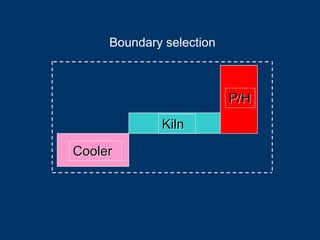

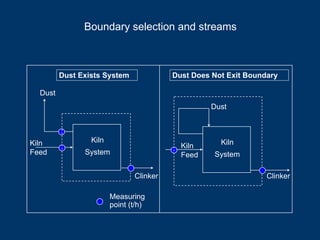

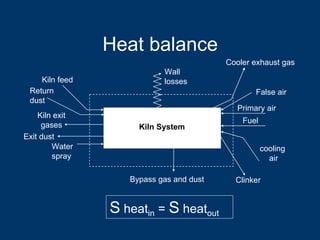

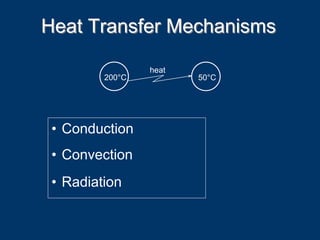

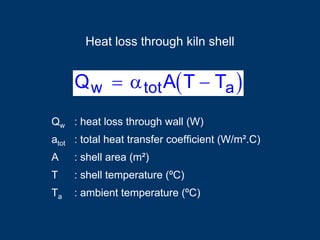

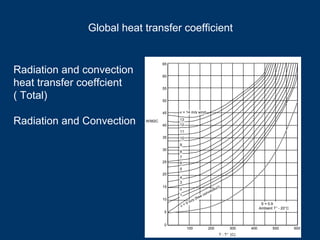

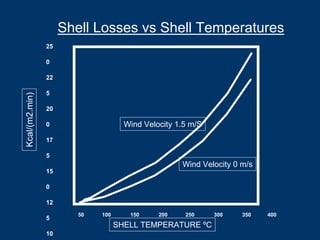

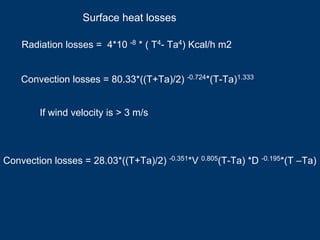

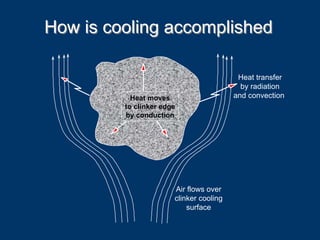

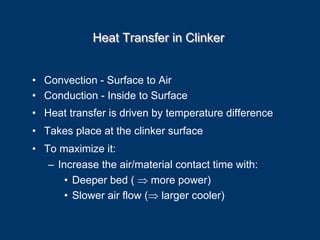

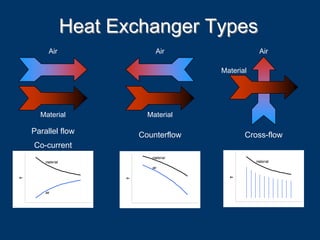

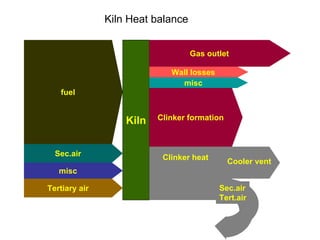

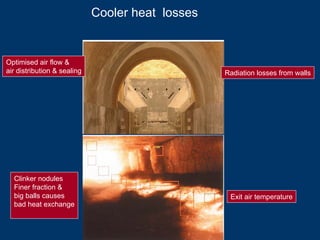

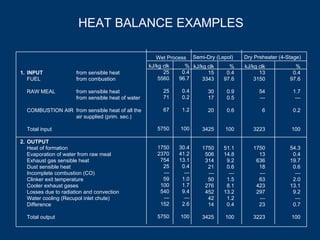

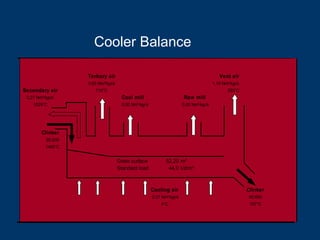

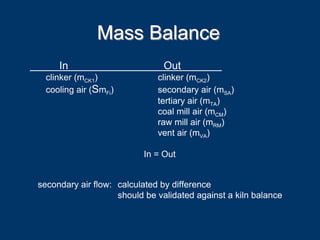

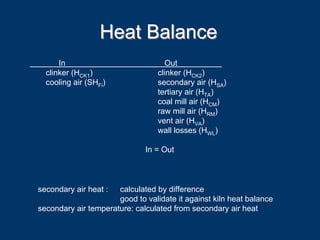

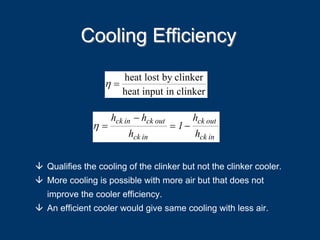

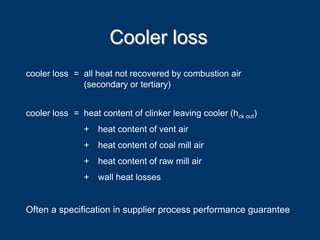

This document discusses heat optimization in cement production processes. It identifies major areas of heat loss, including through shell radiation, unused heat in exit gases and cooler exit air. The goal of design engineers is to minimize heat losses and optimize consumption. Key factors that influence heat losses are discussed for the preheater, calciner, kiln and cooler systems. Different burner and flame types are also examined in relation to combustion efficiency and heat distribution in the kiln. Heat balances are provided as examples to account for all heat inputs and outputs in the clinker production process.

![Operating results cooler

Coolerefficiency[%]

Combustion air Nm³/kgKl.

0,75 0,8 0,85 0,9 0,95

60

65

70

75

80

85

Standard - cooler New - competition REPOL RS

New-type coolers

Old-type coolers](https://image.slidesharecdn.com/heatoptimisation-pradeepkumar-130426034411-phpapp01/85/Heat-optimisation-pradeep-kumar-63-320.jpg)