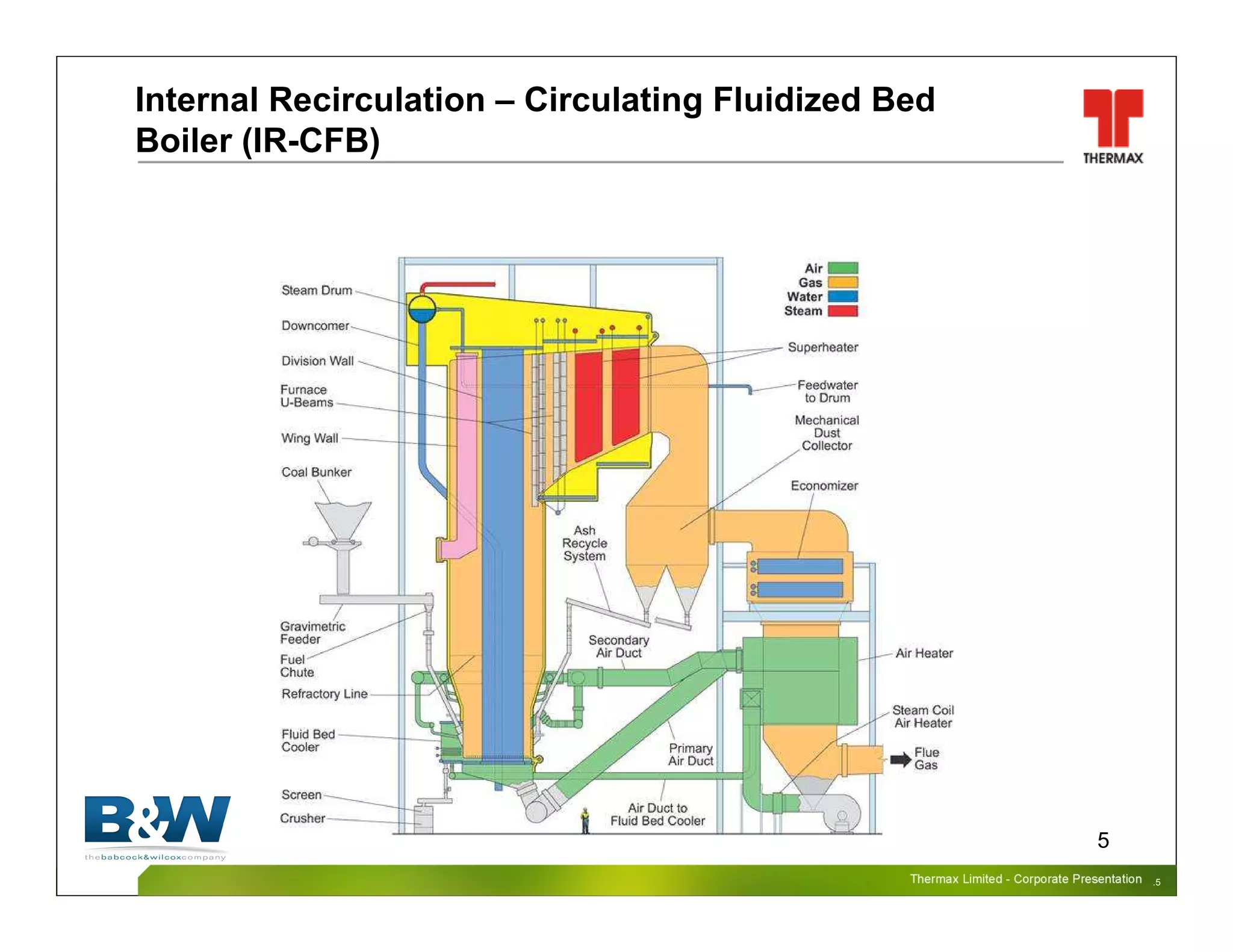

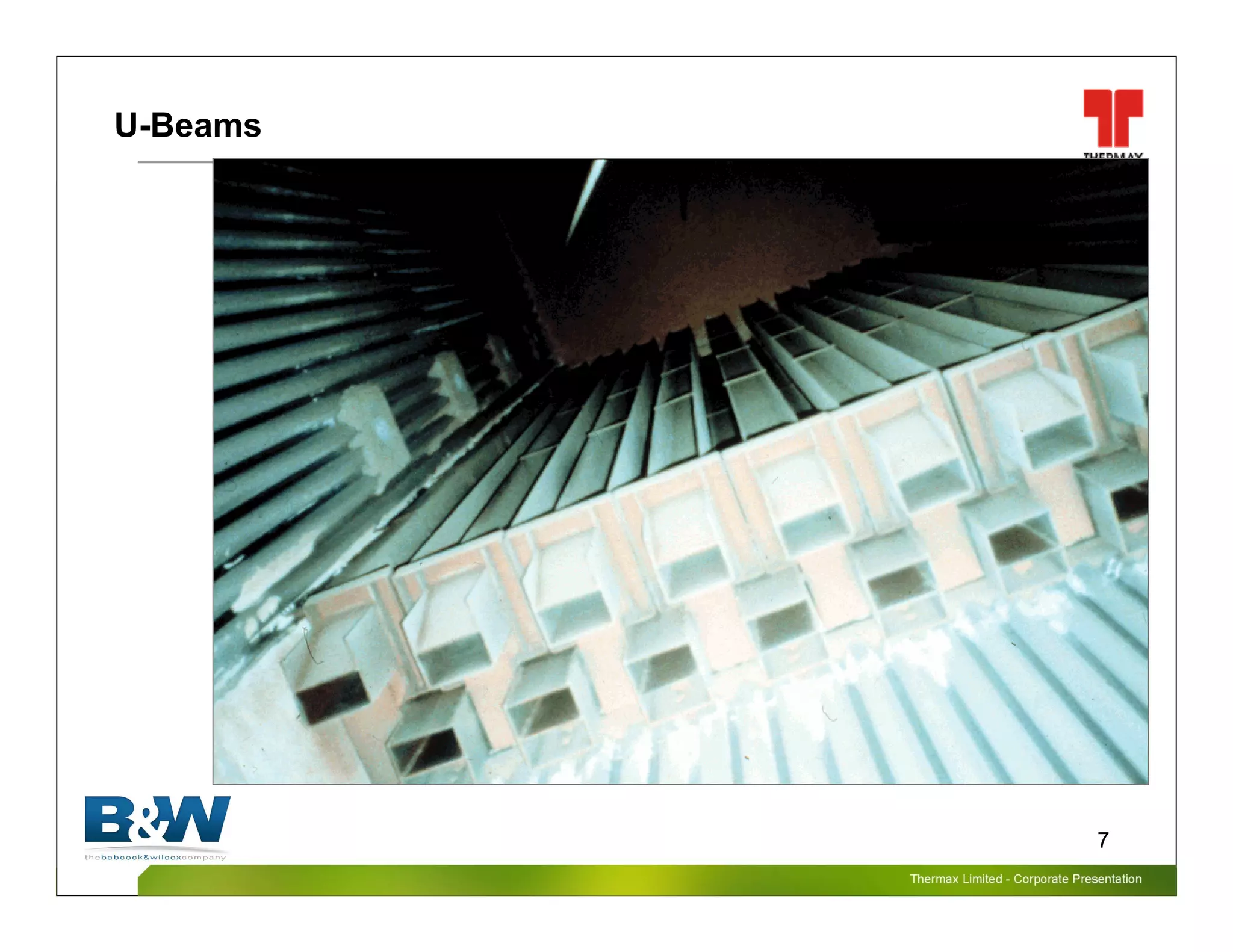

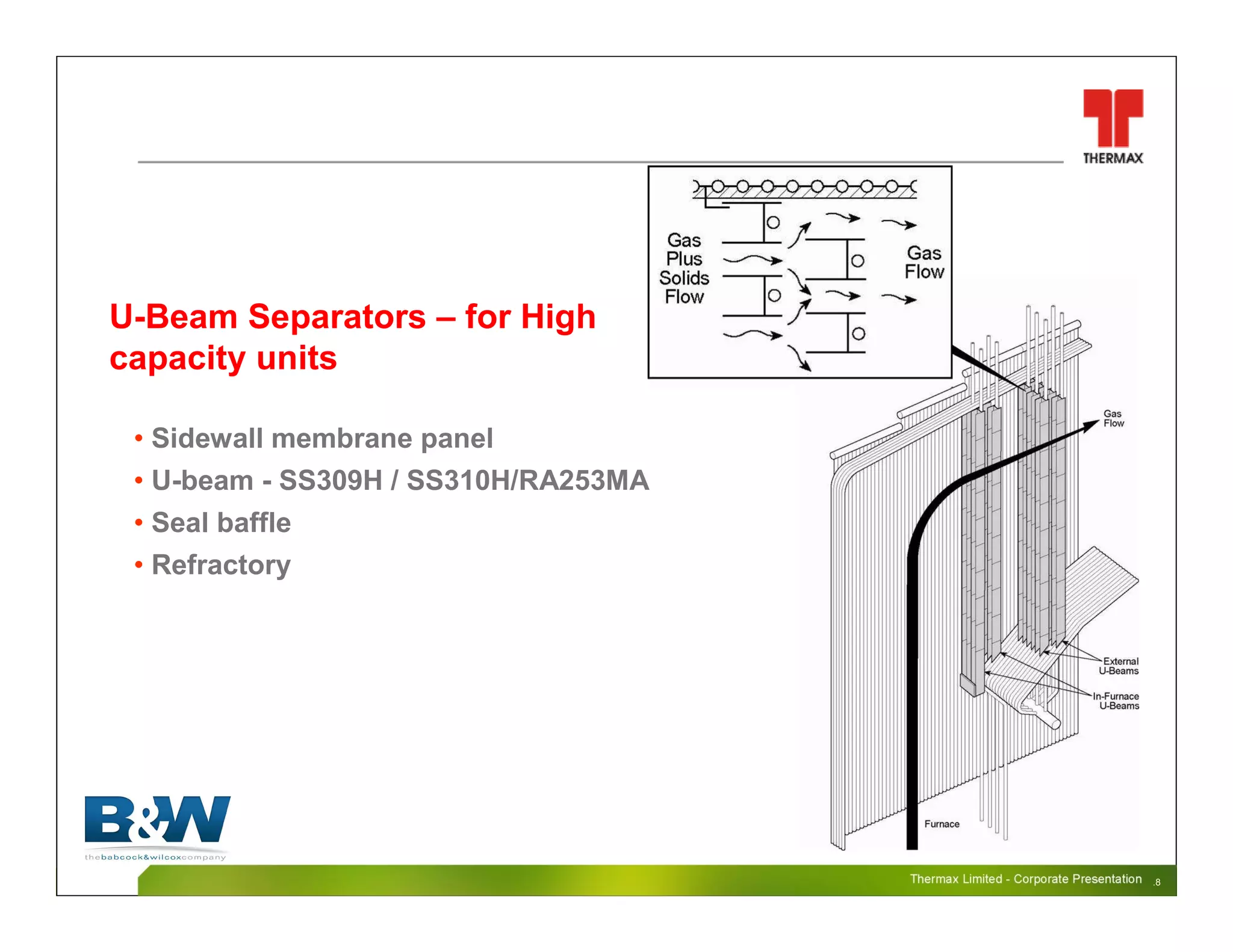

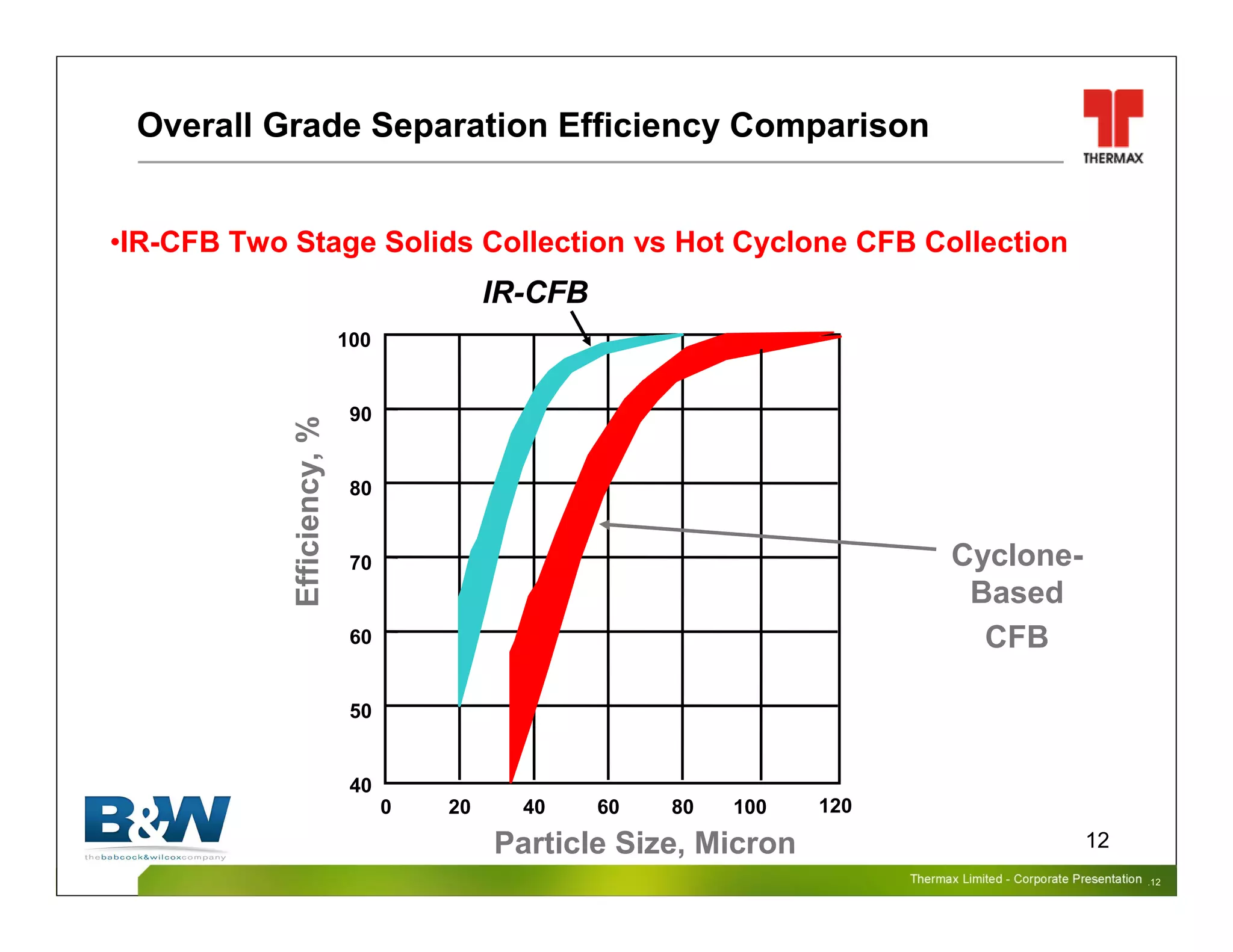

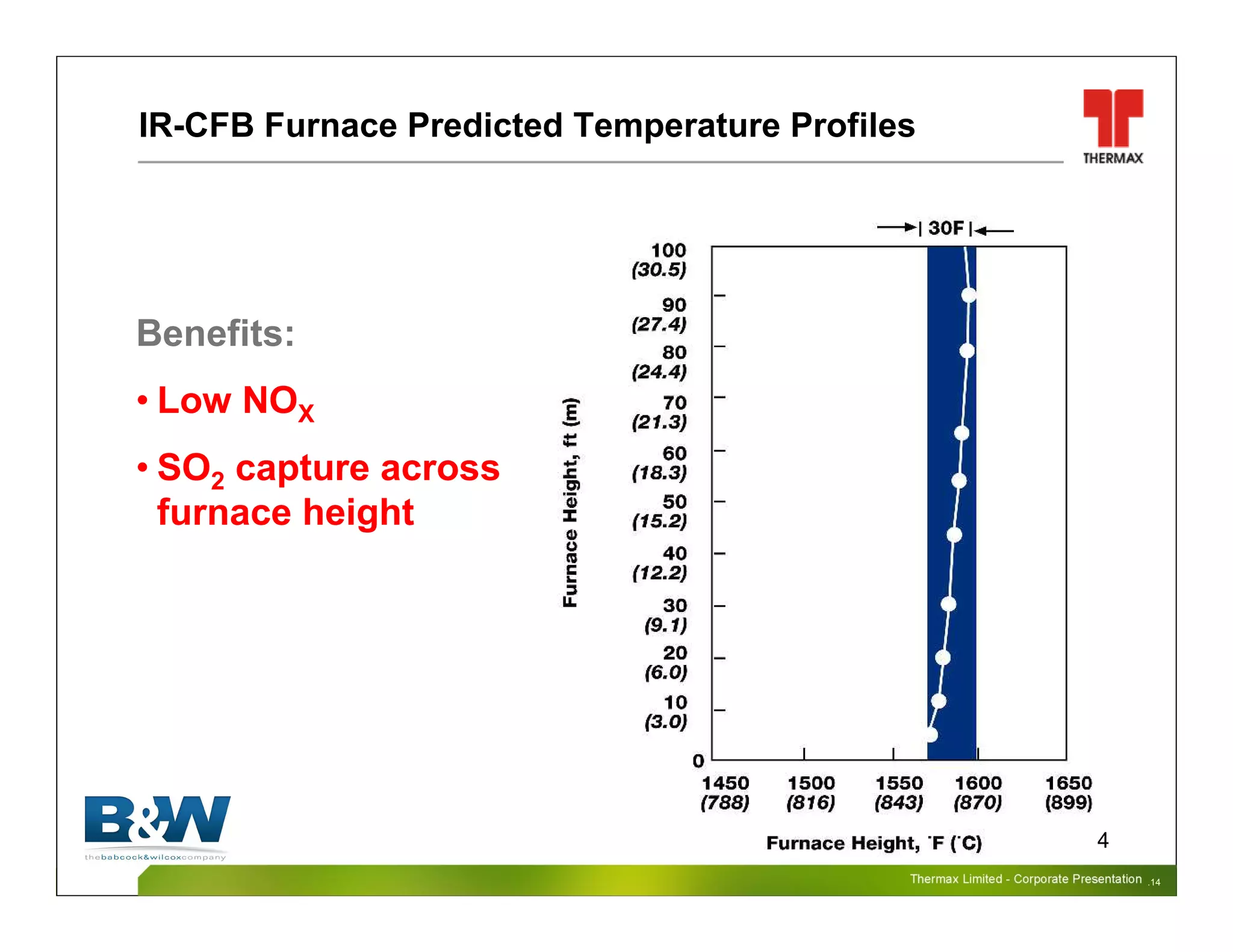

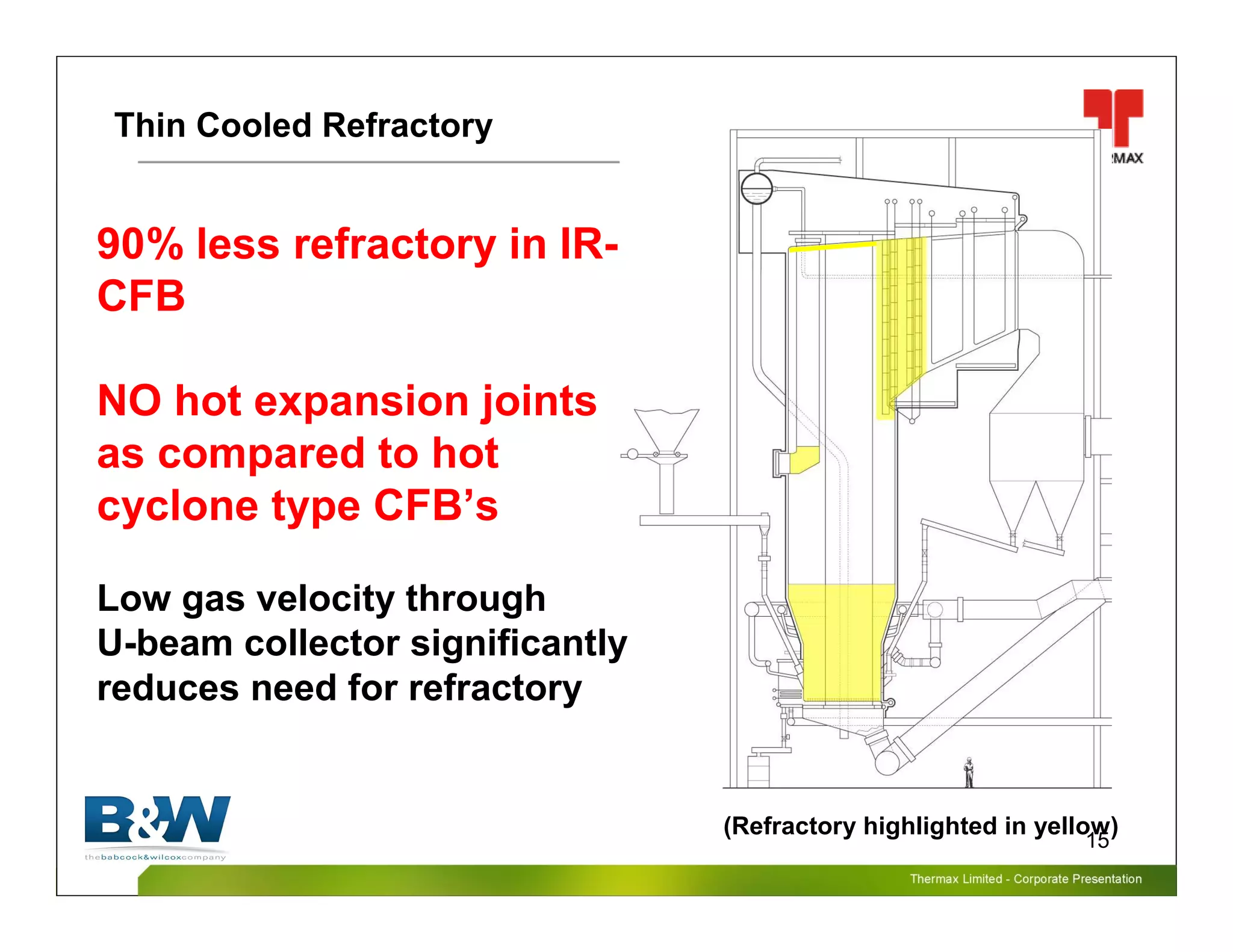

The document discusses Thermax Limited's internal recirculation circulating fluidized bed (IR-CFB) boiler technology. Some key benefits of IR-CFB boilers include higher separation efficiency across smaller particle sizes, uniform furnace temperatures, thin refractory, and lower operating and maintenance costs compared to other CFB designs. IR-CFB boilers also offer benefits such as high heat transfer rates, extended turndown ratios without auxiliary fuels, low auxiliary power needs, and fast shutdown times. The technology is supported by the operational experience of multiple installed IR-CFB boilers.