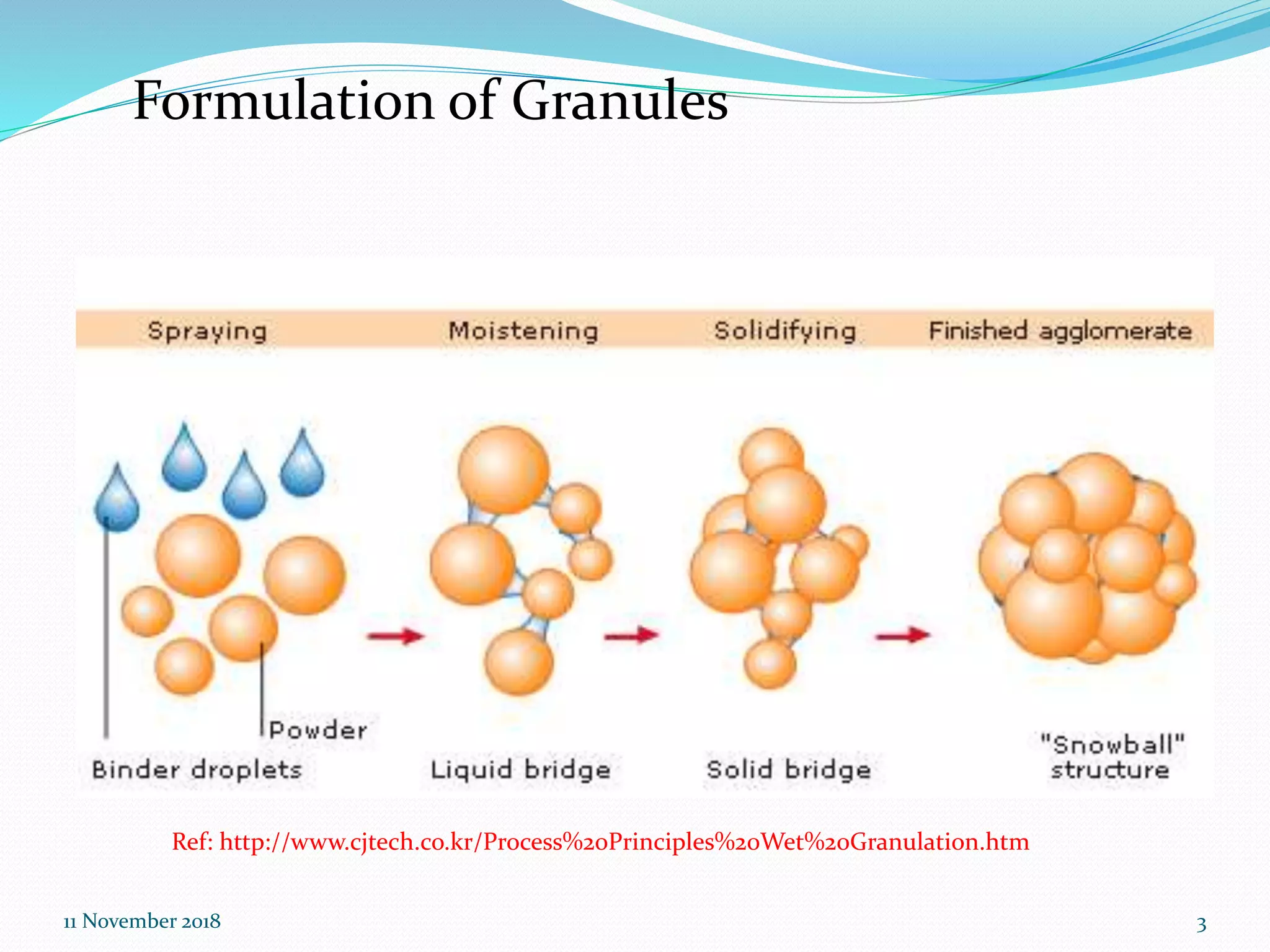

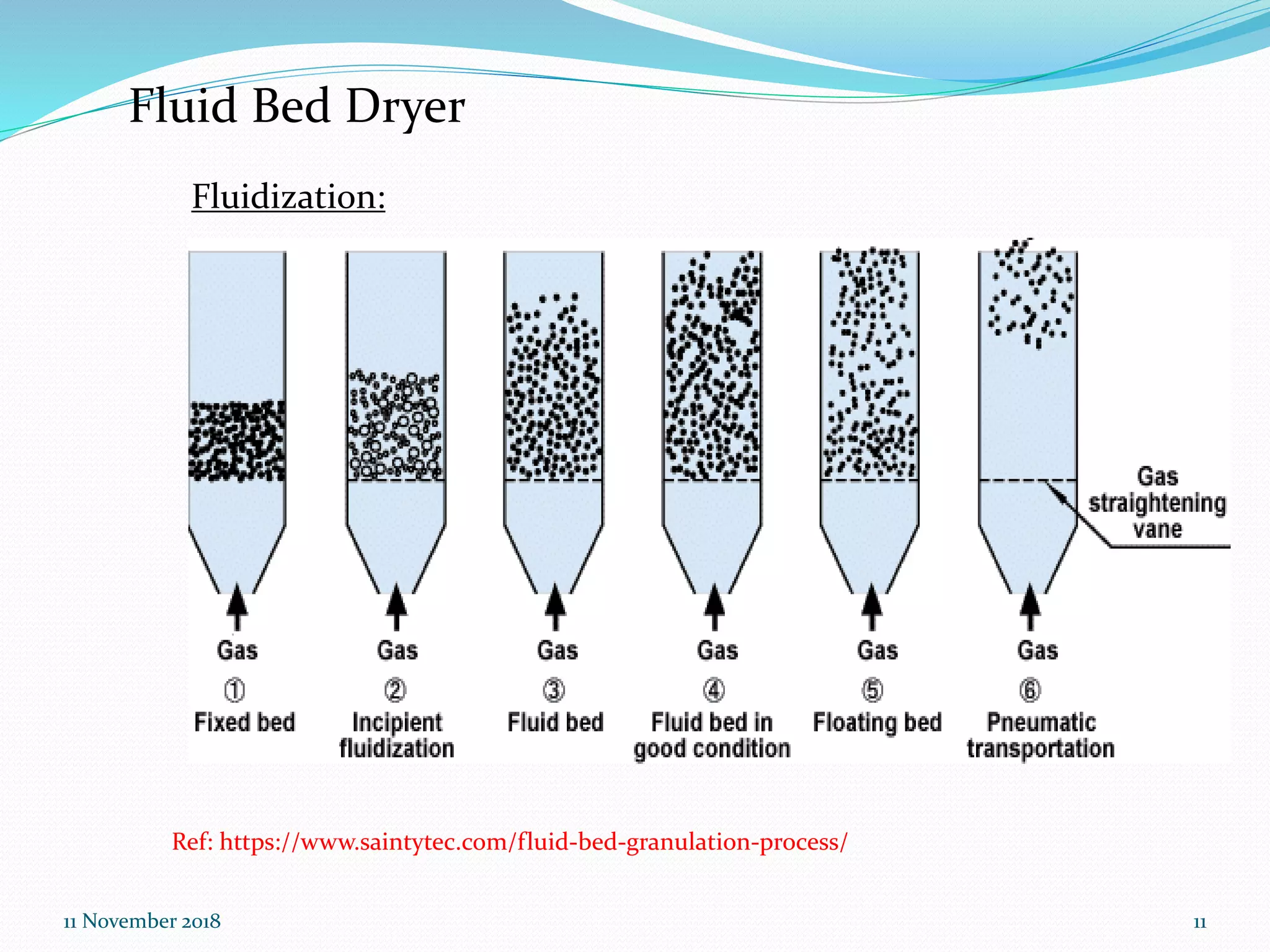

Granulation is the process of forming powders or particles into larger, agglomerated granules. It involves collecting particles together using compression or a binding agent to form bonds between them. Granulation is widely used in tablet and pellet manufacturing. The document outlines the key steps in wet granulation processing which includes mixing, drying, screening, and blending. It describes the equipment used such as rapid mixer granulators, fluid bed dryers, and octagonal blenders. The goal of granulation is to improve powder flow and the mechanical properties of tablets for efficient production.