This document reports the results of a grain size analysis of two sandstone samples:

1) Dupitila sandstone - The histogram shows a bimodal distribution with modes between 0.5-1 mm and 0.25-0.125 mm. The median is 0.175 mm. Sorting is well at 2.68 and skewness is finely skewed at 2.21.

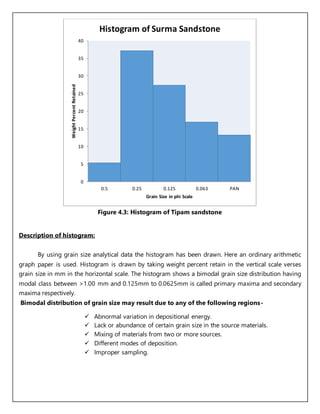

2) Surma Group sandstone - The histogram again shows a bimodal distribution with modes above 1 mm and 0.125-0.063 mm. The median is 0.9 mm. Sorting is well at 2.206 and skewness is finely skewed at 1.259.