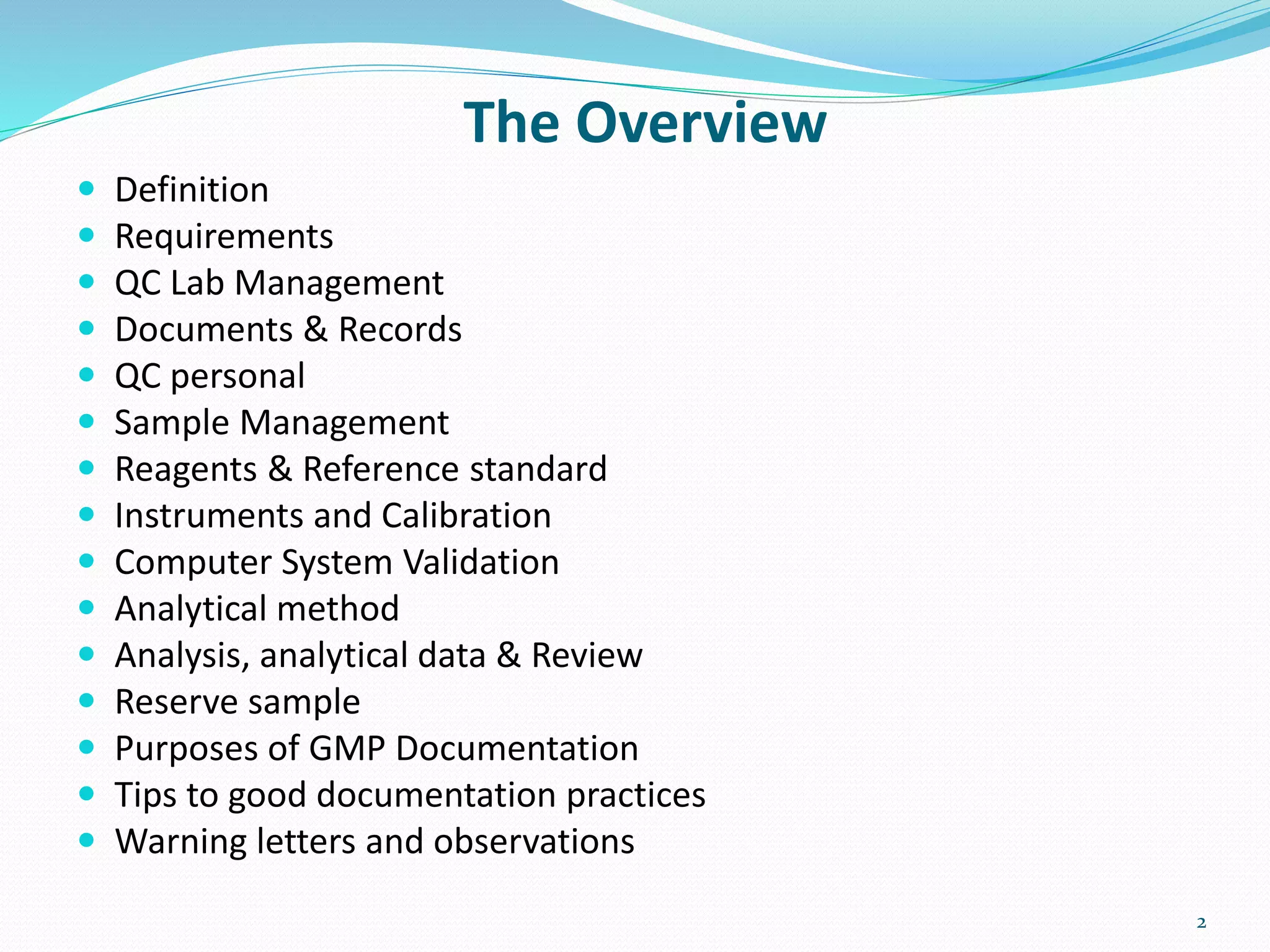

The document provides definitions and guidelines for quality control laboratory management. It discusses definitions of key terms, requirements for quality control documentation and records, personnel qualifications, sample management, use of reagents and reference standards, instrument calibration, analytical methods, and data review. The document emphasizes that quality control laboratories must meet regulatory requirements and operate according to good practices and management systems to ensure the quality of pharmaceutical products.