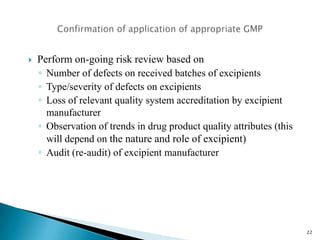

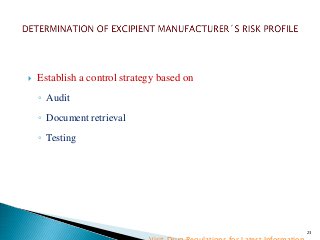

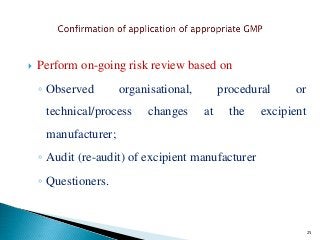

This presentation outlines the guidelines and practices concerning good manufacturing practices (GMP) for excipients used in medicinal products, as mandated by the European Directive 2011/83/EC. It emphasizes the importance of risk assessment and management in ensuring the quality and safety of excipients, detailing processes for evaluating risks from various sources and documenting compliance with GMP principles. The document encourages pharmaceutical professionals to utilize resources from the non-profit organization Drug Regulations for the latest regulatory information.