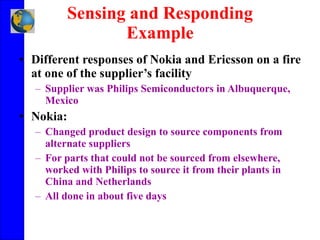

The document discusses global supply chain management strategies for a multinational automotive company. It outlines the company's manufacturing locations around the world and production responsibilities at each plant. It then discusses factors like foreign competition, technology diffusion, costs, taxes, and regulations that companies must consider for an effective global supply chain. Risk management strategies are also summarized, including redundancy, rapid response, and adaptability across the supply chain.