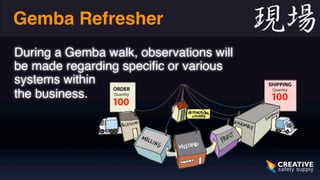

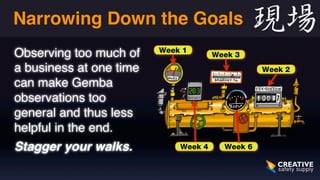

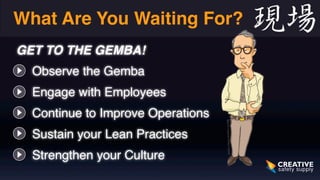

The document discusses the gemba method, which emphasizes the importance of observing and engaging directly in the workplace to identify and improve inefficiencies. Gemba walks are strategic observations aimed at recognizing issues affecting production, fostering safety, and enhancing overall efficiency. Effective implementation requires careful planning and preparation to ensure authentic observation of normal employee behavior.